Wet and short flow-process pretreatment process of fabric

A short-process, pre-treatment technology, applied in the field of pre-treatment, can solve the problems of high energy consumption, low efficiency, high emission, etc., achieve the effect of reducing resources and environmental protection, reducing energy consumption, and improving the mercerizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

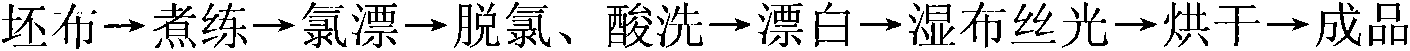

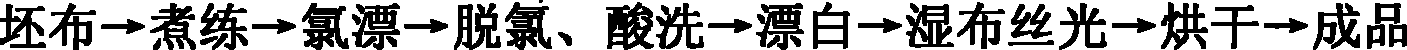

[0019] A wet-wet short-flow pretreatment process for fabrics, characterized in that: the following steps are carried out in sequence:

[0020] Firstly, the gray cloth of 27.8tex*27.8tex pure ramie plain cloth after singeing treatment is scoured, the amount of NaOH is 30-35g / l, the amount of self-made penetrating agent is 3.5g / l, and the steaming temperature is 100±1 ℃; steaming time is 55min;

[0021] Secondly, after the scouring treatment, the gray cloth is washed with water and then bleached with chlorine. The amount of sodium chlorite in the bleach solution is 6g / l, the pH value is adjusted to 10.5, and it is stacked at 20°C for 45 minutes;

[0022] Again, carry out oxygen bleaching treatment after the gray cloth after chlorine bleaching treatment is dechlorinated, pickling, the H in the oxygen bleaching liquid 2 o 2 The dosage is 4.0g / l, the stabilizer is 2.0g / l, the water glass is 3.5g / l, the homemade penetrant M3.5g / l, the pH value is adjusted to 10.5, the steaming tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com