A kind of mercerizing penetrant and preparation method thereof

A technology of mercerizing penetrant and starter alcohol, which is applied in the fields of plant fiber, fiber treatment, textile and paper making, and can solve problems such as easy foaming, increased production cost, and environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

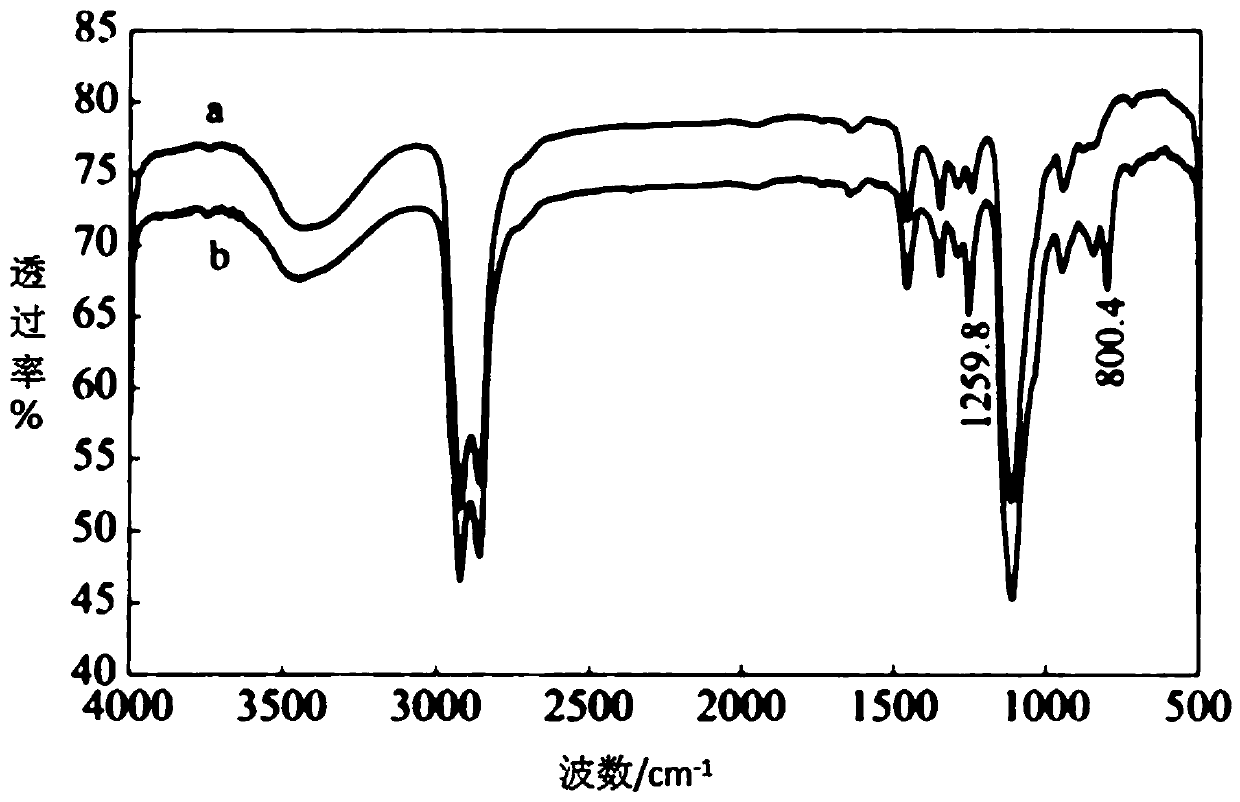

Image

Examples

Embodiment 1

[0069] Table 1

[0070]

[0071] The proportioning ratio of each raw material component of the penetrant in this embodiment is shown in Table 1. Wherein, the alkyl diphenyl ether sulfonate is sodium octyl diphenyl ether sulfonate; the fatty alcohol polyoxyethylene sulfate is isomerized decanol polyoxyethylene ether sulfate (EO number is 3);

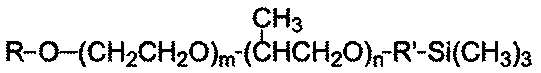

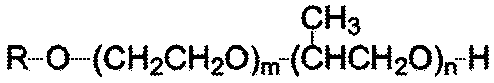

[0072] Preparation of silicon-modified polyether:

[0073] (1) Preparation of polyether: In a pressure reactor, add 100 parts of isomeric tridecanol (EXXAL TM 13) and KOCH 3 (The amount is 0.2% of the weight of isomeric tridecyl alcohol), replace the air in the kettle with nitrogen for 3 times, heat up to 110° C., and dehydrate for 30 minutes under a vacuum environment below −0.09 MPa. Then the temperature was raised to 120°C, and ethylene oxide was slowly added dropwise (the molar ratio of ethylene oxide to isotridecyl alcohol was 9:1), and the ring-opening polymerization was carried out at a pressure of 0.2 MPa and a temperature o...

Embodiment 2

[0086] The proportioning ratio of each raw material component of the penetrant in this embodiment is shown in Table 1. Wherein, alkyl diphenyl ether sulfonate is sodium dodecyl diphenyl ether sulfonate; fatty alcohol polyoxyethylene sulfate is isomeric tridecyl alcohol polyoxyethylene ether sulfate (EO number is 4);

[0087] Preparation of silicon-modified polyether:

[0088] (1) Preparation of polyether: In a pressure reactor, add 100 parts of isooctyl alcohol (6-methyl-1-heptanol) and KOH (the amount is 0.2% of the weight of isooctyl alcohol), and replace the kettle with nitrogen Inner air 3 times, heat up to 110°C, and dehydrate for 30min in a vacuum environment below -0.09MPa. Then the temperature was raised to 120°C, and ethylene oxide was slowly added dropwise (the molar ratio of ethylene oxide to isooctyl alcohol was 3:1), and the ring-opening polymerization was carried out at a pressure of 0.25 MPa and a temperature of 130°C. After the ethylene oxide is finished, the...

Embodiment 3

[0100] The proportioning ratio of each raw material component of the penetrant in this embodiment is shown in Table 1. Among them, alkyl diphenyl ether sulfonate is sodium decyl diphenyl ether sulfonate; fatty alcohol polyoxyethylene sulfate is C 12-14 Alcohol polyoxyethylene ether sulfate (EO number is 3);

[0101] Preparation of silicon-modified polyether:

[0102] (1) Preparation of polyether: In a pressure reactor, add 100 parts of isomeric tridecanol (EXXAL TM 13) and KOH (the amount of which is 0.3% of the weight of isomeric tridecanol), replace the air in the kettle with nitrogen for 3 times, heat up to 110°C, and dehydrate for 30min under a vacuum environment below -0.09MPa. Then the temperature was raised to 120°C, and ethylene oxide was slowly added dropwise (the molar ratio of ethylene oxide to isotridecyl alcohol was 10:1), and the ring-opening polymerization was carried out at a pressure of 0.35 MPa and a temperature of 130°C. After the dropwise addition, ripen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com