Pavement structure for structure transfer and performance recovery of semi-rigid base asphalt pavement

A semi-rigid base and asphalt pavement technology, applied in road repair, roads, roads, etc., can solve the problems of waste of resources, occupation of land resources, secondary environmental pollution, etc., to prevent secondary pollution, save resources, and prevent rainwater. Penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

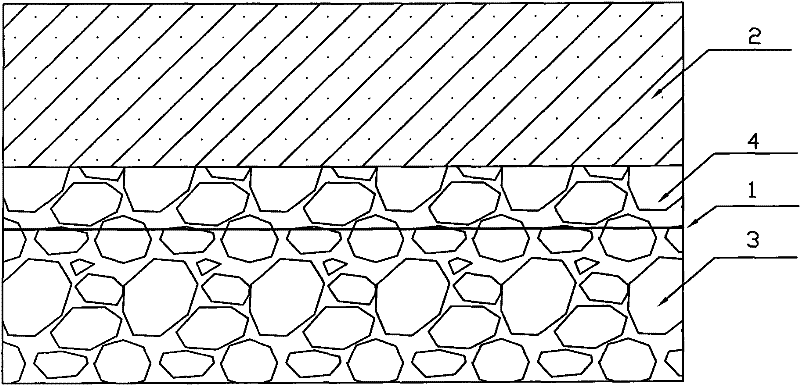

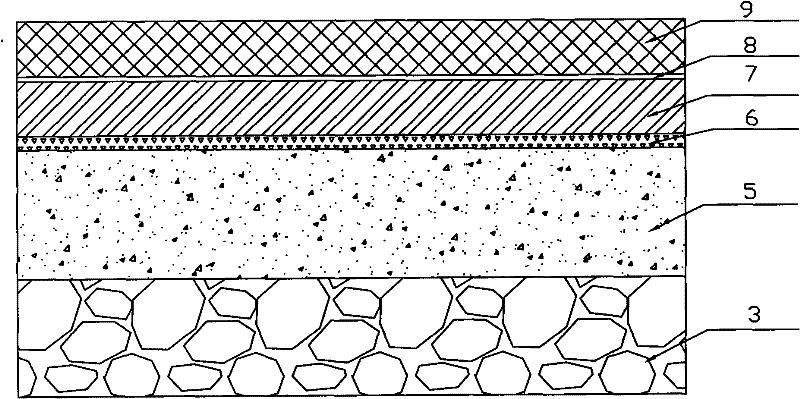

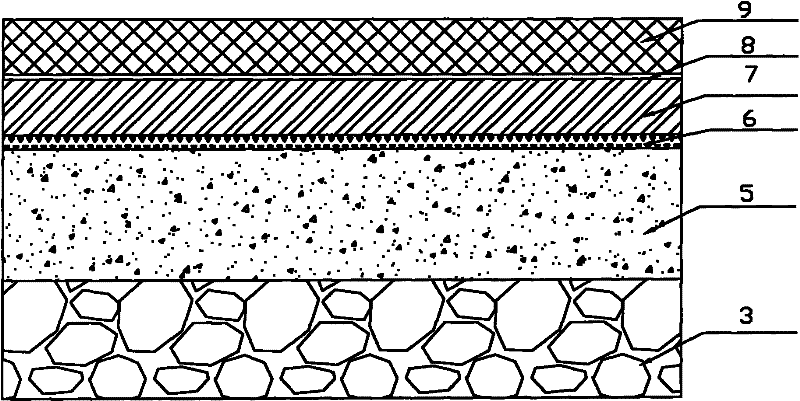

[0026] see figure 1 , figure 2 , a pavement structure for semi-rigid base asphalt pavement structure conversion and performance recovery, the semi-rigid base asphalt pavement is composed of the original asphalt pavement semi-rigid base 1, the original asphalt pavement surface layer 2, the original asphalt pavement semi-rigid base 1 The undamaged part is the undamaged semi-rigid base 3 of the original asphalt pavement, and the damaged part of the semi-rigid base 1 of the original asphalt pavement is the damaged semi-rigid base 4 of the original asphalt pavement. The above is the cold recycled semi-flexible base layer 5 after structural conversion, the modified emulsified asphalt slurry seal layer 6 is on the cold recycled semi-flexible base layer 5, and the modified emulsified asphalt slurry seal layer 6 is the lower layer of the asphalt pavement 7, the asphalt pavement The lower layer 7 is a modified emulsified asphalt adhesive layer 8, and the modified emulsified asphalt ad...

Embodiment 2

[0039] see figure 1 , figure 2 , a pavement structure used for semi-rigid base asphalt pavement structure conversion and performance recovery, the construction method of which is the same as in Example 1.

[0040] The thickness of the undamaged semi-rigid base 3 of the original asphalt pavement is 11 cm.

[0041] The cold recycled semi-flexible base layer 5 is mixed with the following materials by weight, milling material: 100 parts; new aggregate: 21 parts; asphalt: 3.1 parts; inorganic binder: 2.0 parts; water: 12 parts The milling material is composed of the material obtained from the damaged semi-rigid base layer 4 of the original asphalt pavement, the material obtained from the milling original asphalt surface layer 2, and the material obtained from the damaged semi-rigid base layer 4 of the original asphalt pavement and The mass ratio between the materials obtained by milling the original asphalt surface layer 2 is 100:65; the asphalt is foamed asphalt, which is forme...

Embodiment 3

[0048] see figure 1 , figure 2 , a pavement structure used for semi-rigid base asphalt pavement structure conversion and performance recovery, the others are the same as in Embodiment 1.

[0049] The semi-rigid base layer 1 of the original asphalt pavement has been completely damaged.

[0050] The cold recycled semi-flexible base layer 5 is mixed with the following materials by weight, milling material: 100 parts; new aggregate: 15 parts; asphalt: 2.8 parts; inorganic binder: 1.7 parts; water: 10 parts The milling material is composed of the material obtained from all semi-rigid bases 1 of the original asphalt pavement and the material obtained from milling the original asphalt surface layer 2, and the material obtained from all semi-rigid bases 1 of the original asphalt pavement and milled The mass ratio between the materials obtained from the original asphalt surface layer 2 is 100:45; the asphalt is foamed asphalt, which is formed by mixing high-temperature hot-melt asph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com