Rigid hinged support for bridge

A rigid hinge and bridge technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of insufficient support, troublesome installation and disassembly, and influence of support force, and achieve the purpose of reducing peak stress, improving safety, and facilitating installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

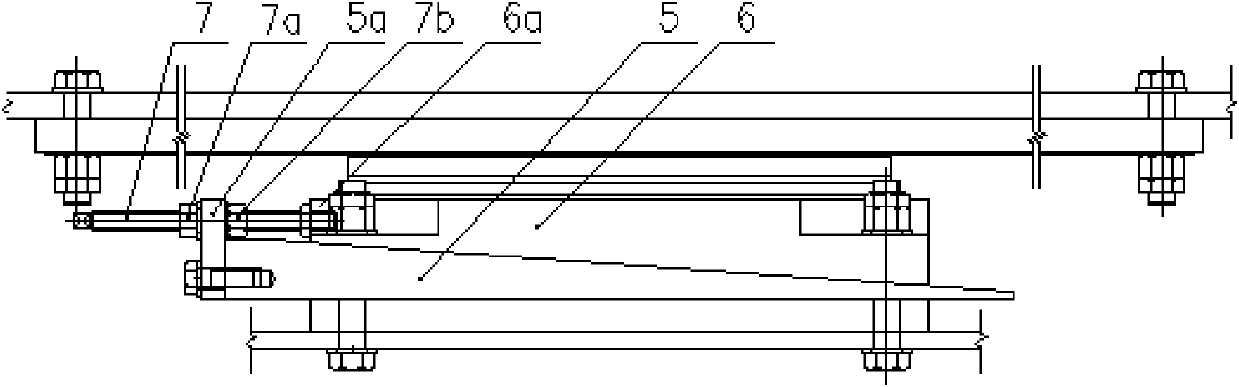

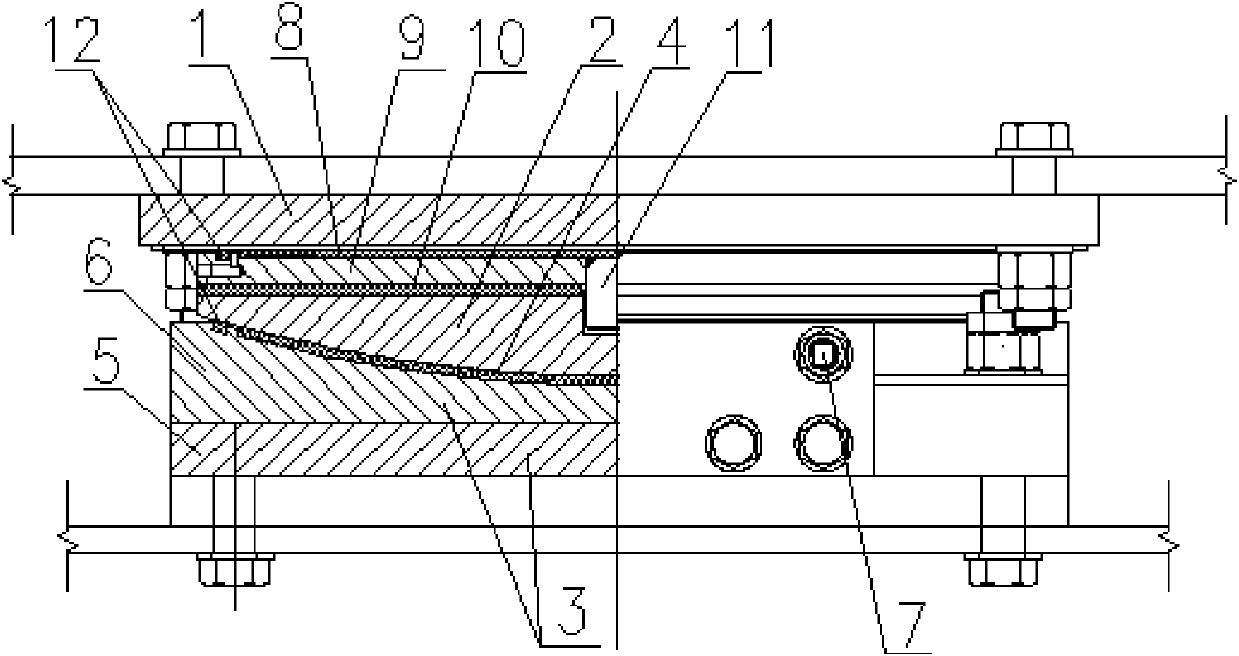

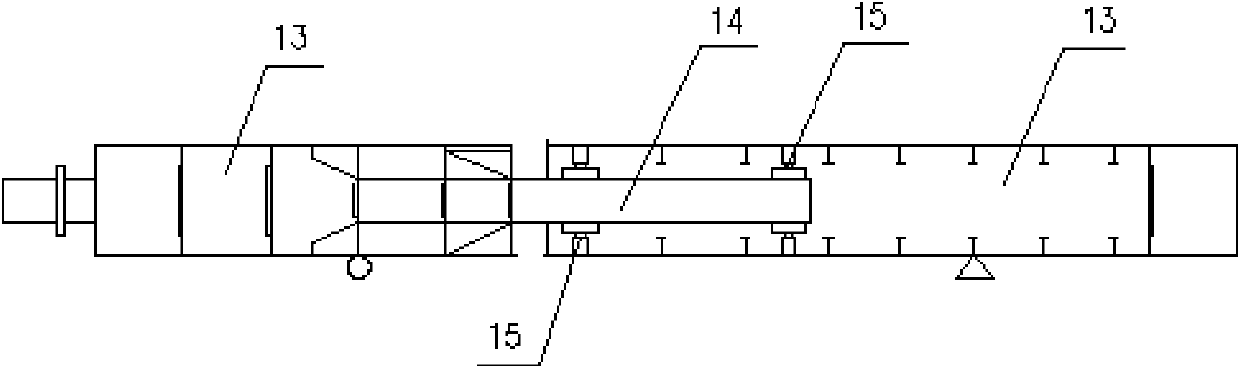

[0016] Example: such as figure 1 , 2 Shown: a rigid hinge support for bridges, including an upper support plate 1, a spherical crown liner 2 and a lower support plate 3 arranged from top to bottom, the spherical crown liner 2 and the lower support A spherical sliding plate 4 is arranged between the plates 3, and the lower support plate 3 is composed of a bearing seat 5 and an adjusting plate 6 whose cross-sections are all wedge-shaped, and the bearing seat 5 and the adjusting plate 6 are bonded by two inclined surfaces , at the same end of the bearing seat 5 and the adjustment plate 6, the bearing seat adjustment lug 5a and the adjustment plate adjustment lug 6a are respectively arranged, and an adjustment screw 7 is screwed on the two lugs; the upper support plate and the spherical crown Between the lining boards 2, a plane slide plate 8, an intermediate steel lining board 9 and a vibration-damping rubber pad 10 are sequentially arranged from top to bottom, and a shear forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com