Flexible shield-type hydraulic support for coal mine

A hydraulic support and flexible cover technology, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problems of easy wrinkling and deformation of steel wire rope, insufficient support strength, and difficult control of collapsed gangue, so as to prevent personal safety accidents of miners , enhance stability and safety, and prevent the effect of falling and hurting accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

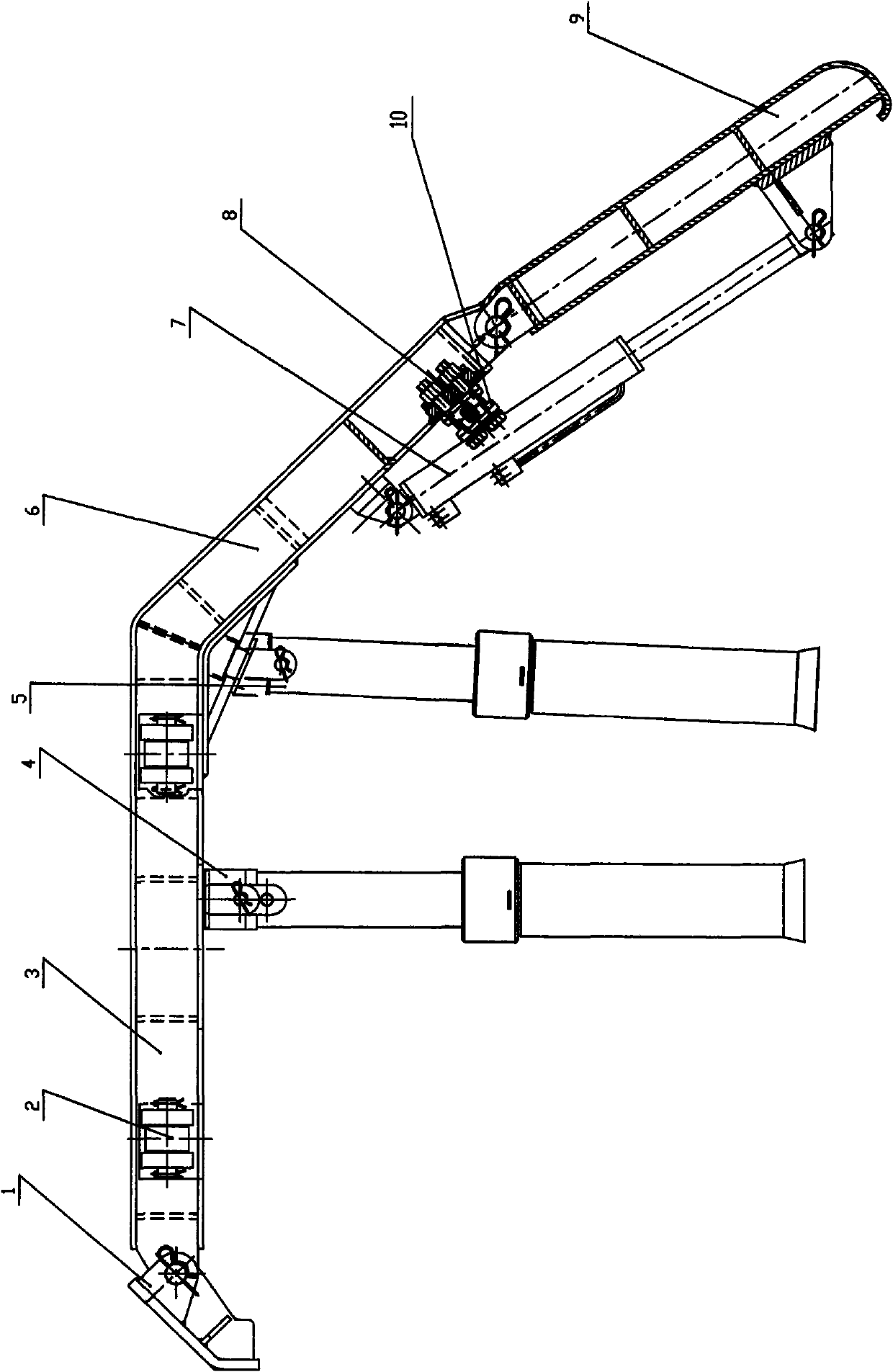

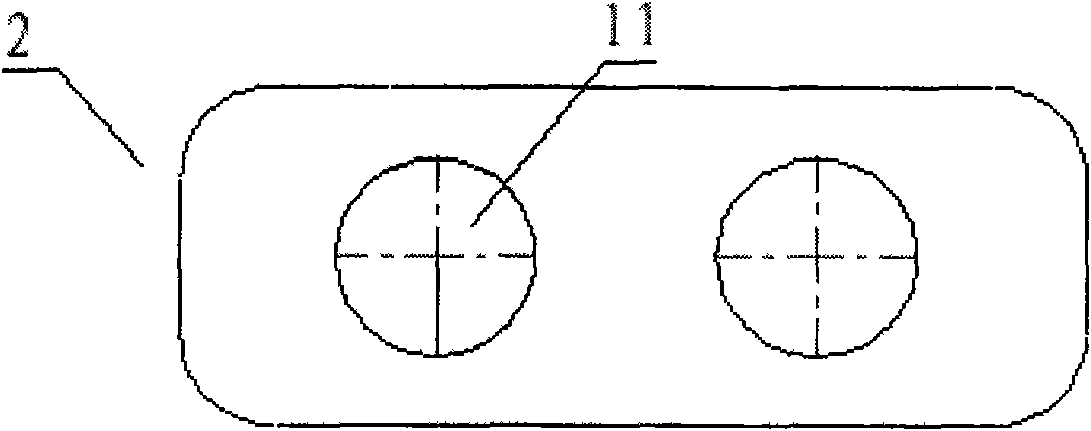

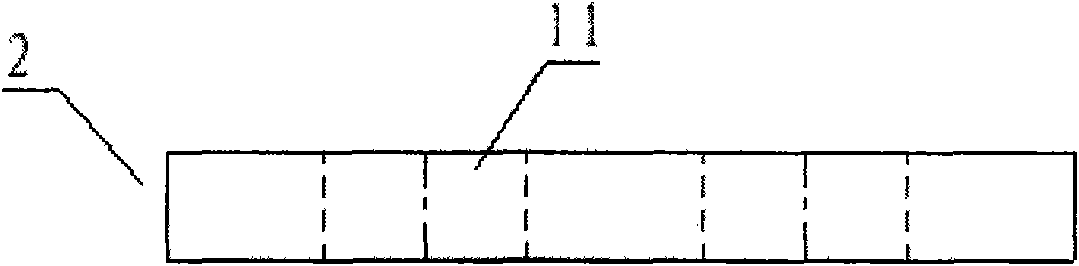

[0022] to combine Figure 1 to Figure 3 As shown, the flexible cover type hydraulic support for coal mines of the present invention includes a top beam 3 and a cover beam 6, and the top beam 3 is equipped with two hinged connectors 2 for hinged adjacent hydraulic support top beams, hingedly connected A hinge hole 11 is opened on the piece 2 . The center of the bottom surface of the top beam 3 is provided with a hydraulic two-way column 4 slightly close to the side of the cover beam 6, and a direction-adjusting hydraulic two-way column 5 is installed at the position where the top beam 3 and the cover beam 6 are connected. The function of the hydraulic two-way column 4 is to increase the working resistance and support strength of the hydraulic support, so as to ensure the support safety of the working face and the life safety of the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com