Method for supporting steel strip connecting bridge of arch-shaped soft rock roadway with large section

A technology of large section and roadway, applied in the direction of tunnel, tunnel lining, earthwork drilling, etc., can solve the problems of insufficient contact and poor roadway support effect, so as to enhance adaptability, reduce deformation, and improve support capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

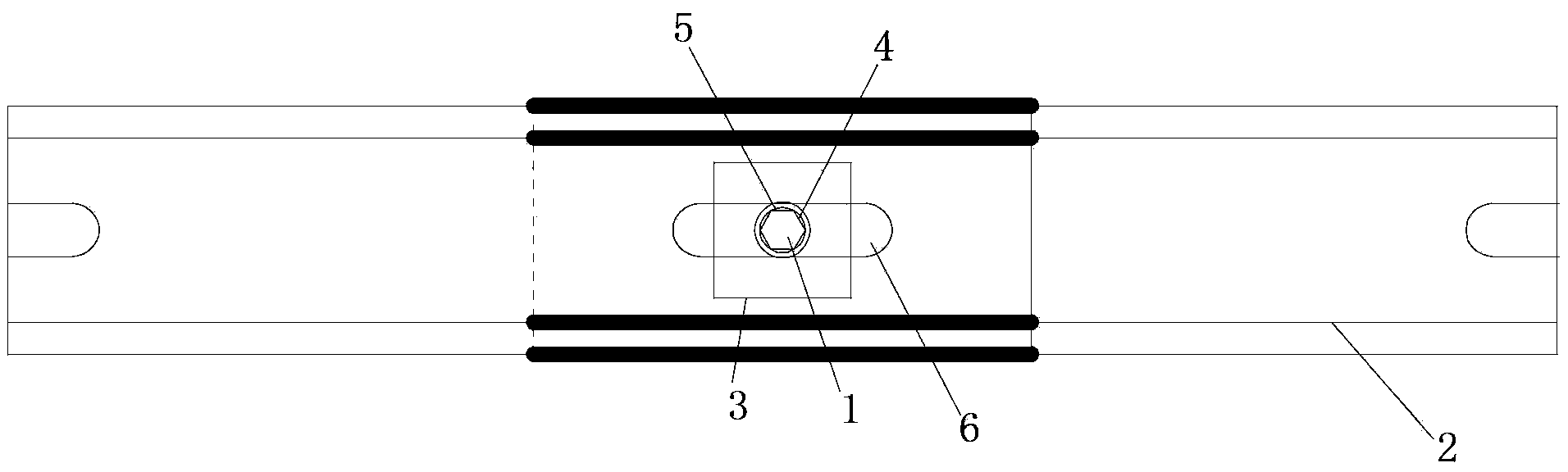

[0018] A large-section arched soft rock roadway steel belt bridge support method, which is to drill the first hole at the middle position of the top of the large-section arched soft rock roadway, such as figure 1 As shown, two W-shaped steel strips 2 are joined along the section of the roadway, so that the first steel strip holes in contact on the two W-shaped steel strips overlap each other to form overlapping holes 6, and ensure that the overlapping holes 6 are located at the above-mentioned drilled holes. Then install the tray 3, pass a high-strength prestressed metal anchor rod 1 through the overlapping hole 6, and tighten the nut 4 with a drilling machine to reach the prestressed anchor rod. Finally, take the first drill hole as the center, follow the extension direction of the two W-shaped steel strips, and drill holes to both sides in sequence. The prestressed anchor rod is used to anchor the W-shaped steel belt. However, it should be noted that the last steel belt hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com