Hydraulic oil cylinder

A technology of hydraulic cylinders and cylinder barrels, which is applied in the field of hydraulic cylinders and can solve problems such as easy swinging of piston rods, mixing, and affecting work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

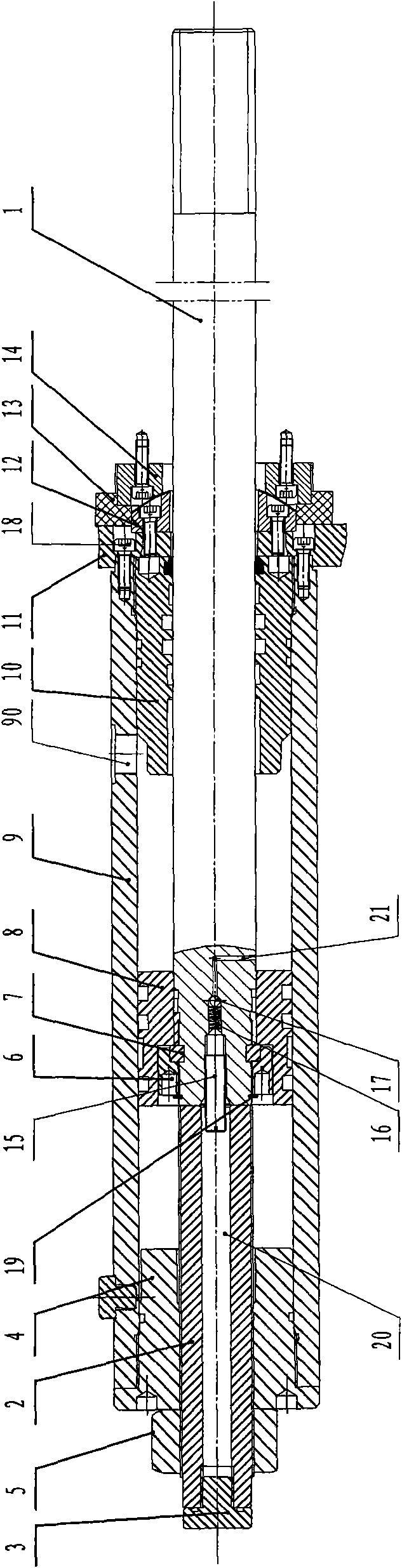

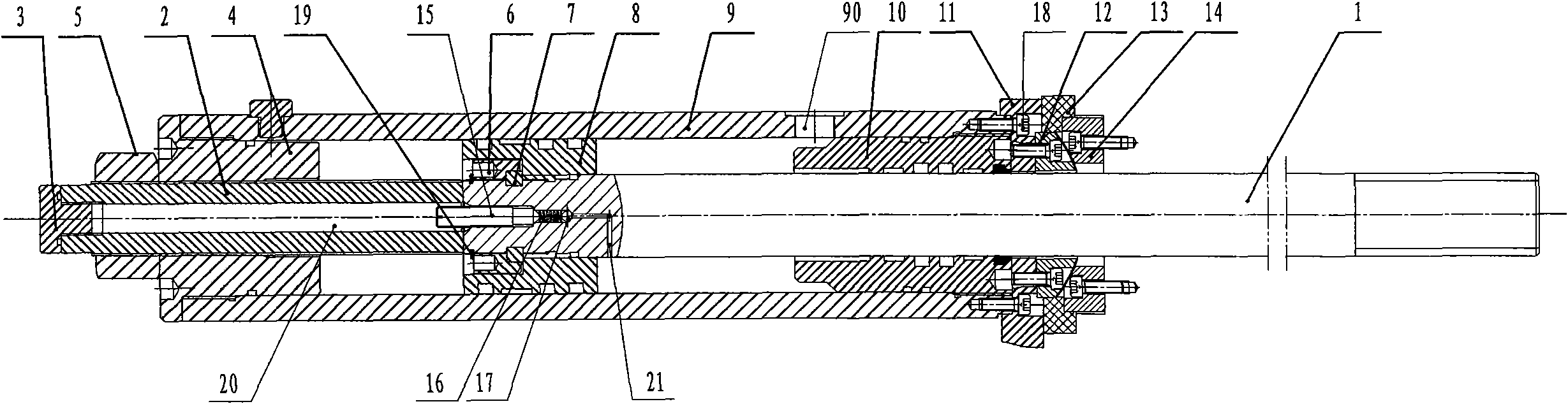

[0015] Implementation: such as figure 1 As shown, the hydraulic cylinder described in this embodiment is mainly composed of a cylinder tube 9, a rear end cover 4, a piston rod 1, a piston 8, and a front end cover composed of a guide sleeve 10 and a stop sleeve 11. The guide sleeve 10 is connected to the cylinder tube 9 in a sealed manner. The stop sleeve 11 is firmly connected to the front end of the cylinder tube 8 through a connecting screw 18. The cylinder wall of the cylinder tube 9 is provided with a hydraulic oil pipe connection port 90, and the piston 8 passes through a compression nut 6, a key 7. The shaft is fixed on the end of the piston rod 1 with a retaining ring 19. A screw hole is opened in the center of the rear end cover 4, and a limit screw 2 is installed on the screw hole. The outer end of the limit screw 2 is fixed by a lock nut 5. The length of the limit screw 2 extending into the cylinder 9 can be adjusted. Adjust the stroke of the piston rod 1. When conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com