Photocatalytic reaction differential automatic test system

An automatic test system and photocatalytic reaction technology, which is applied in the field of catalytic chemical reaction test experimental system, can solve the problems of lack of reaction pressure control, etc., and achieve the effect of simple and clear system, simple connection and easy uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

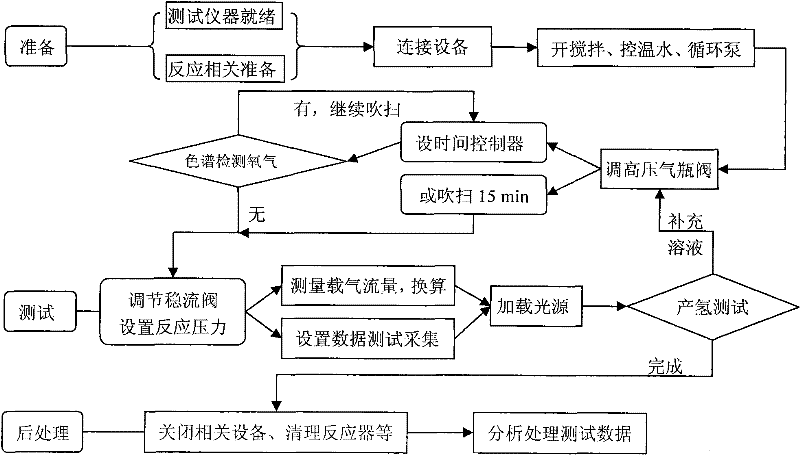

[0031] The content of the present invention will be described in further detail below in conjunction with the accompanying drawings.

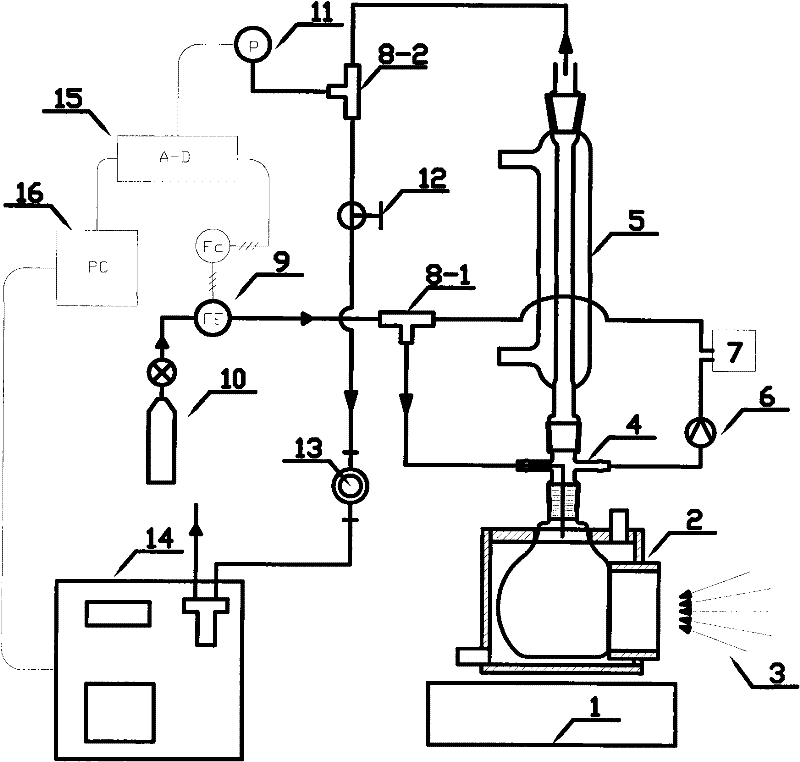

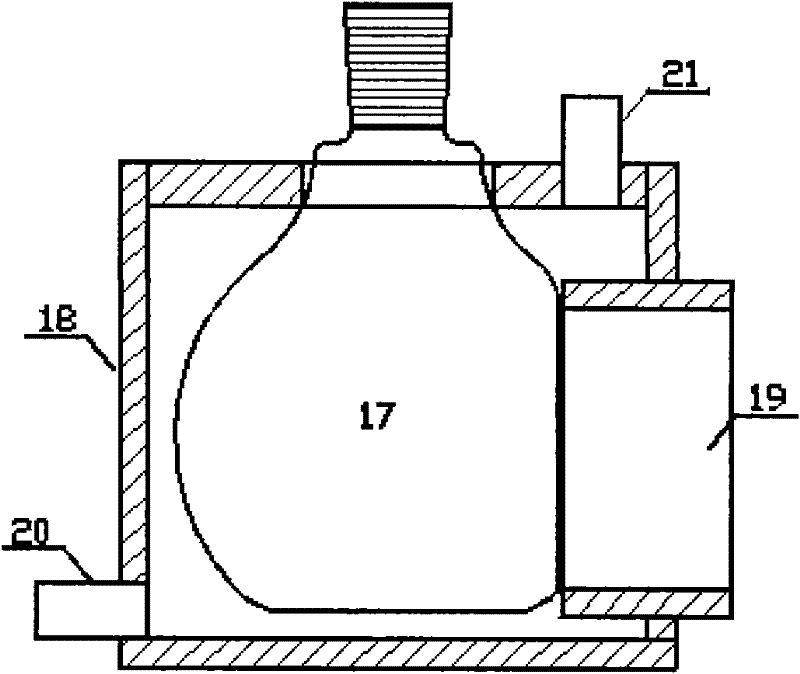

[0032] Such as figure 1 As shown, the photocatalytic reaction differential automatic test system: in this system, the magnetic stirrer 1 is located at the bottom of the photocatalytic reactor 2, and its right side is a xenon lamp point light source 3 (the horizontal side of the light path faces the photocatalytic reactor 2, from left to Right to the light-receiving surface), which is connected to the grinding port, which is used to connect the split air pipe 4. The split air pipe 4 has four ports, the upper and lower are grinding ports, and the left and right are branch pipes; the upper grinding port is connected to the condenser pipe 5; the left branch pipe is connected to the three-way valve 8-1, and the right branch pipe is the circulating gas outlet, which is connected to the circulating pump 6 through the pipeline and the continuous analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com