Integral-type underground high-voltage transformation equipment

A kind of substation equipment, integrated technology, applied in the direction of closed substation, substation, substation/power distribution device shell, etc., can solve the problems of occupying ground resources, hindering the beauty of the environment, and being easy to be damaged, so as to achieve easy maintenance, Easy cooling and heat dissipation, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

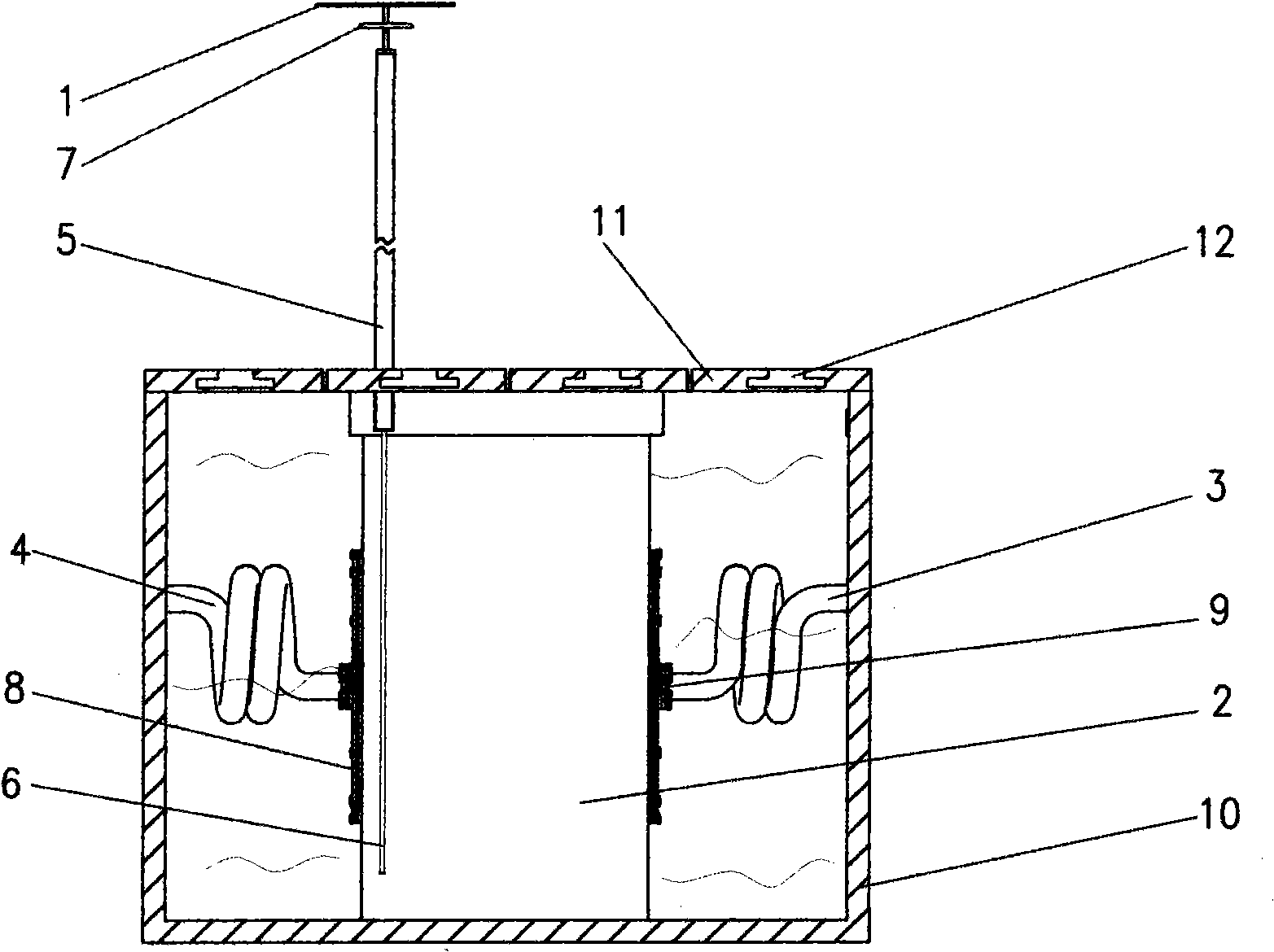

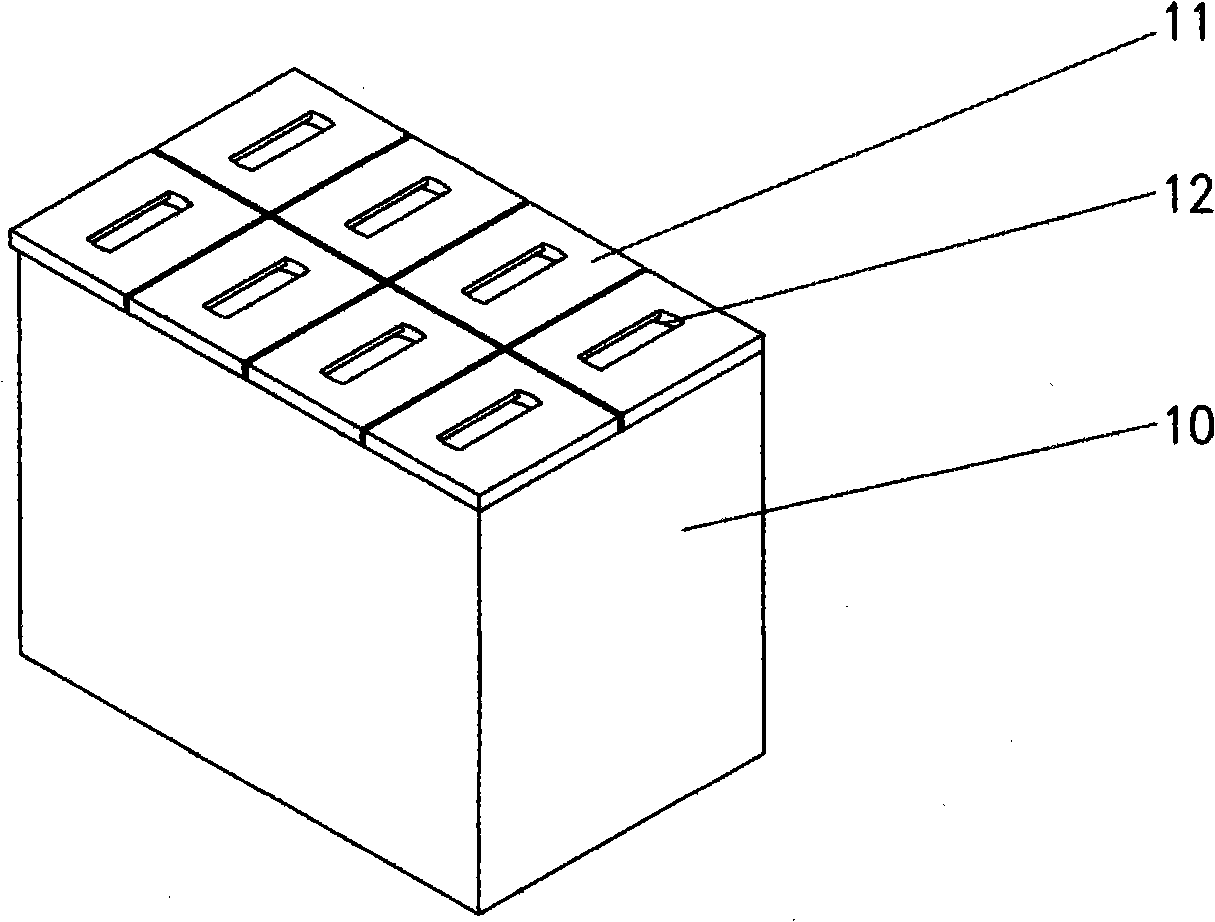

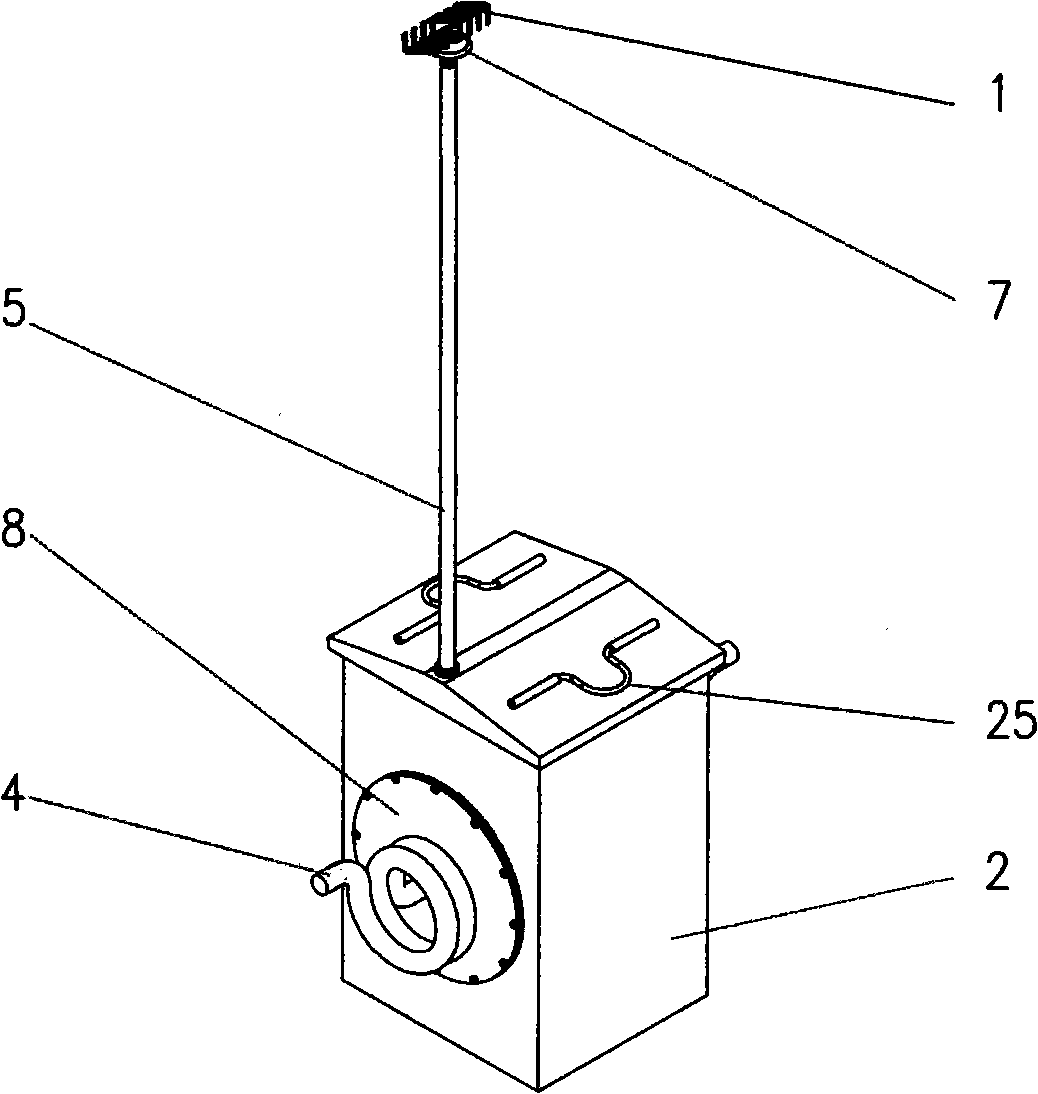

[0016] refer to figure 1 , figure 2 , an integral buried high-voltage power transformation equipment, including a box body 2 and high-voltage power transformation equipment built in the box body 2, the high-voltage power transformation equipment can be a combined transformer, or can be made of multiple electrical components The substation composed of: the box 2 is built in the integral cement pool 10, the top of the cement pool 10 is covered with a cement prefabricated board 11, and the cement prefabricated board is provided with a lifting groove 12; the box 2 is a fully welded airtight structure, and the box body The side wall is provided with an incoming cable 3 and an outgoing cable 4, and the connection between the incoming cable 3 and the outgoing cable 4 and the box body 2 is sealed by a seal 9, and the top of the box body is sealed and connected with an air inlet pipe 5 and an air outlet pipe 6. There is a height difference between the inlet pipe 5 and the air outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com