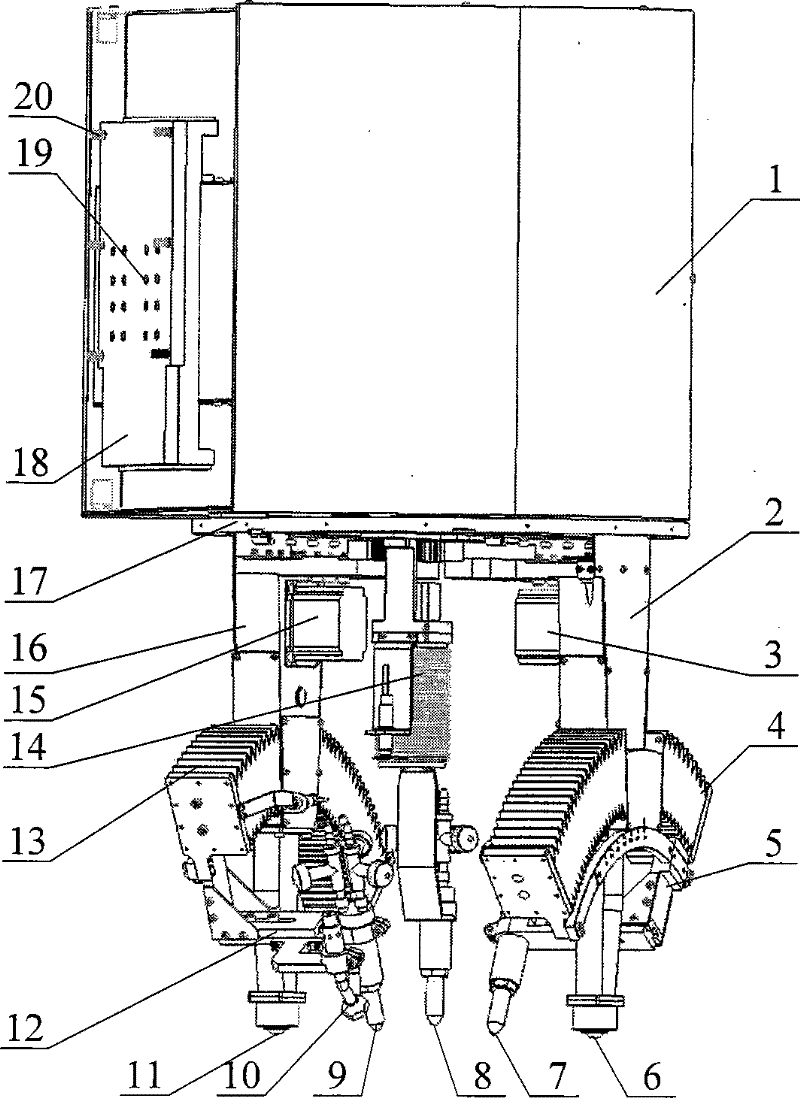

Cutting trajectory planning method and device for cutting workpiece with flame three-torch device

A cutting track and three-torch technology, which is applied to the cutting track planning and device field for cutting workpieces by a flame three-torch device, and can solve the problems that the cutting device cannot meet the requirements and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

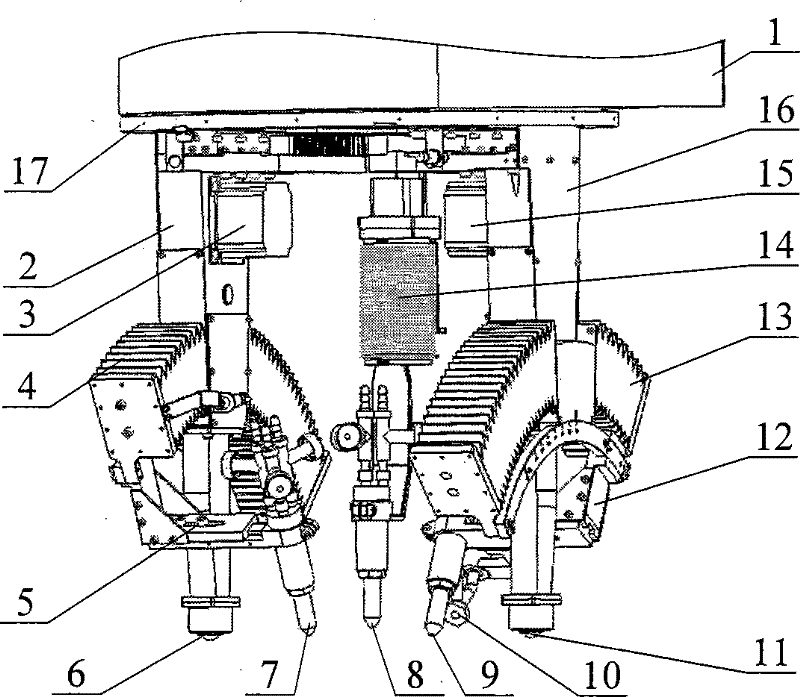

[0044] The technical scheme of the present invention will be further described below in conjunction with the embodiment shown in the accompanying drawings:

[0045] A cutting trajectory planning method for cutting a workpiece using a three-flame cutting torch device, the method includes the following steps:

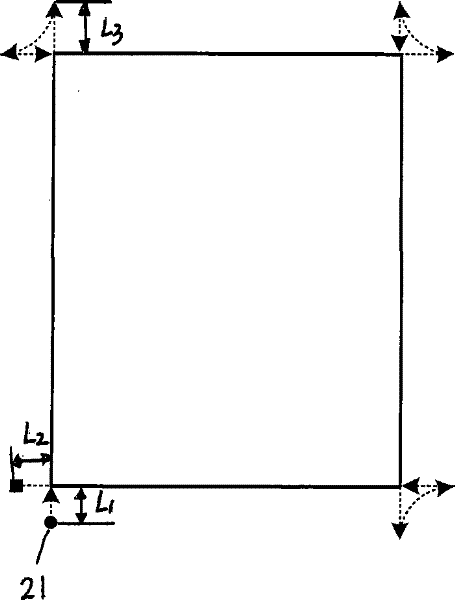

[0046] Step (1), setting a cutting bevel line on the cutting blank, and the cutting bevel line divides the workpiece into a workpiece forming area and a non-workpiece forming area. Workpieces are divided into inner cut workpieces and outer cut workpieces. For inner cut workpieces, the cutting groove line is the inner contour line of the workpiece to be formed. The inner side of the cutting groove line is the non-workpiece forming area, and the outer side is the workpiece forming area; The workpiece, the cutting groove line is the outer contour line of the workpiece to be formed, the inner side of the cutting groove line is the workpiece forming area, and the outer side is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com