Device and method for assembling and disassembling axle box nodes

A technology of dismantling device and axle box, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of long time, large investment, cumbersome procedures, etc., and achieve the effect of simple procedure, saving investment and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

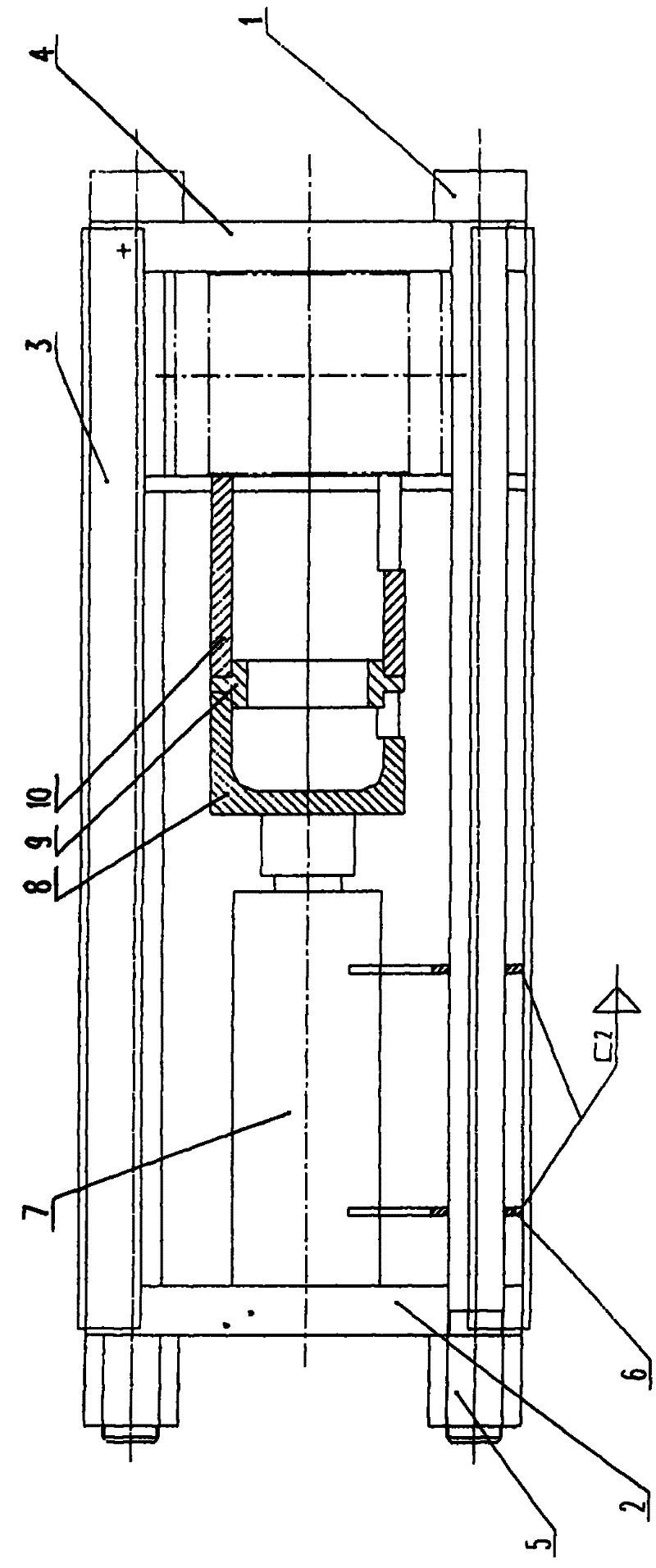

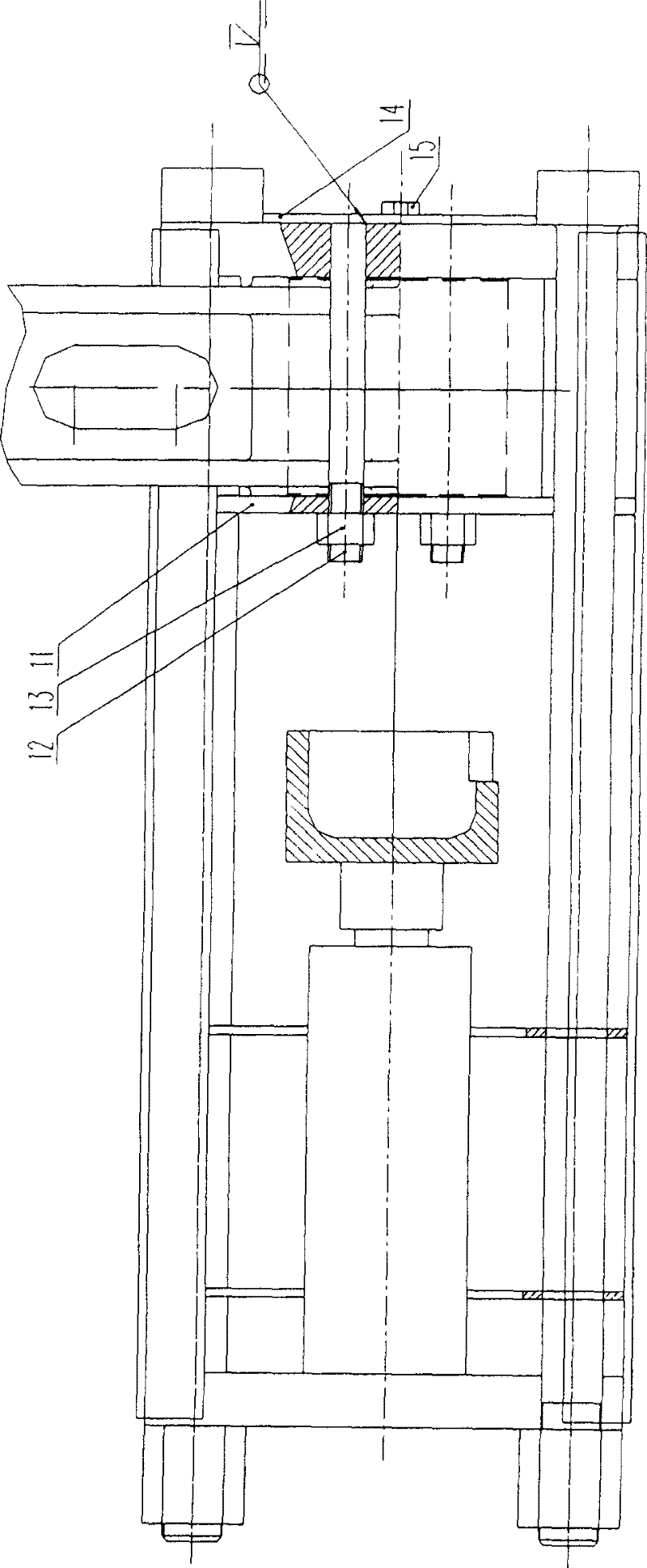

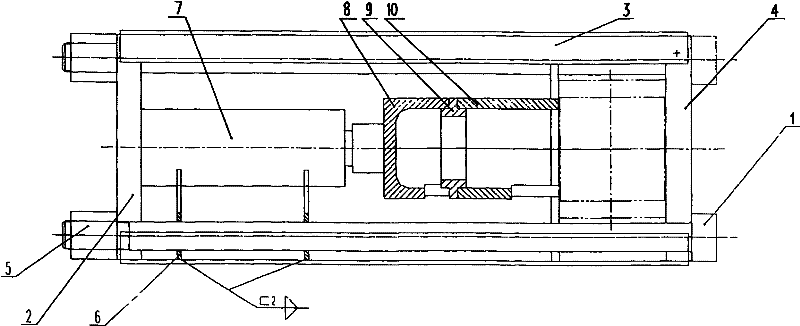

[0017] refer to figure 1 , figure 2 , the present invention comprises pull rod 1, bottom plate 2, angle iron 3, pull plate 4, support plate 6, hydraulic jack 7, stud 12, pressure plate 11, baffle plate 14, pull plate and pressure plate have the circle that axle box node passes through Hole, pull plate, pressure plate, support plate and bottom plate all go through the pull rod, the pull rod is locked on the side of the bottom plate through the tie rod nut 5, the bottom plate and the pull plate are fixedly connected by angle iron, the hydraulic jack is set After the drawing plate and the pressing plate are locked and fixed by the clamping nut 13 and the pressing plate, the baffle is fixed on the outer surface of the drawing plate by the baffle screw 15, and the baffle has a round hole through which the wedge-shaped head of the axle box node passes, and the hydraulic jack Between the pressure plate and the pressure plate, there is an extruding device for extruding the axle box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com