Quantification ball dripping device assembly

A technology of components and balls, applied in the field of hand tools, can solve problems such as unstable clamping of tweezers, troublesome work of installing bearings, inconvenient operation, etc., and achieve the effect of simple structure, flexible use, and reduced operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

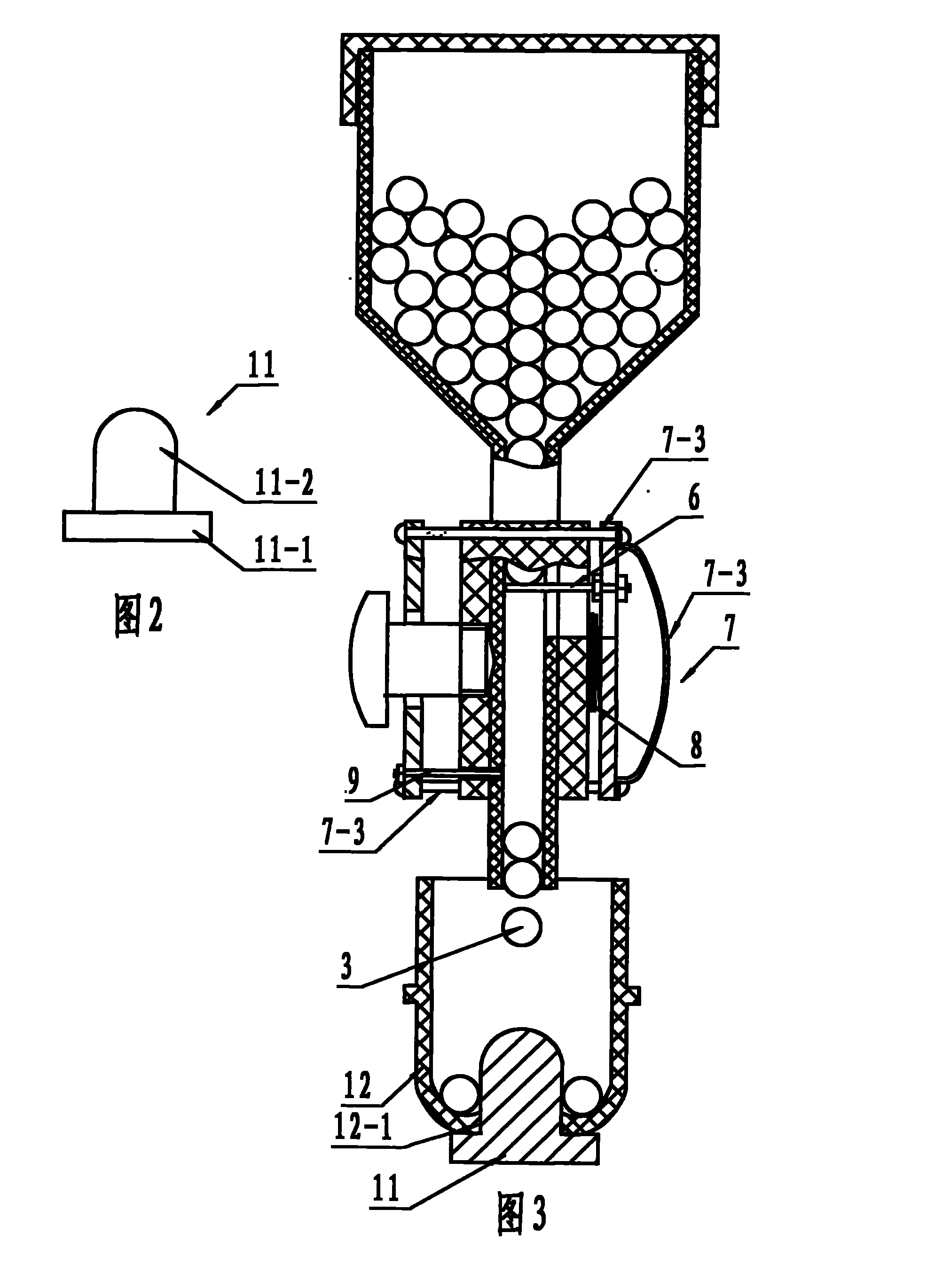

[0013] The invention consists of a quantitative bead dropper and a matching ball distributing base.

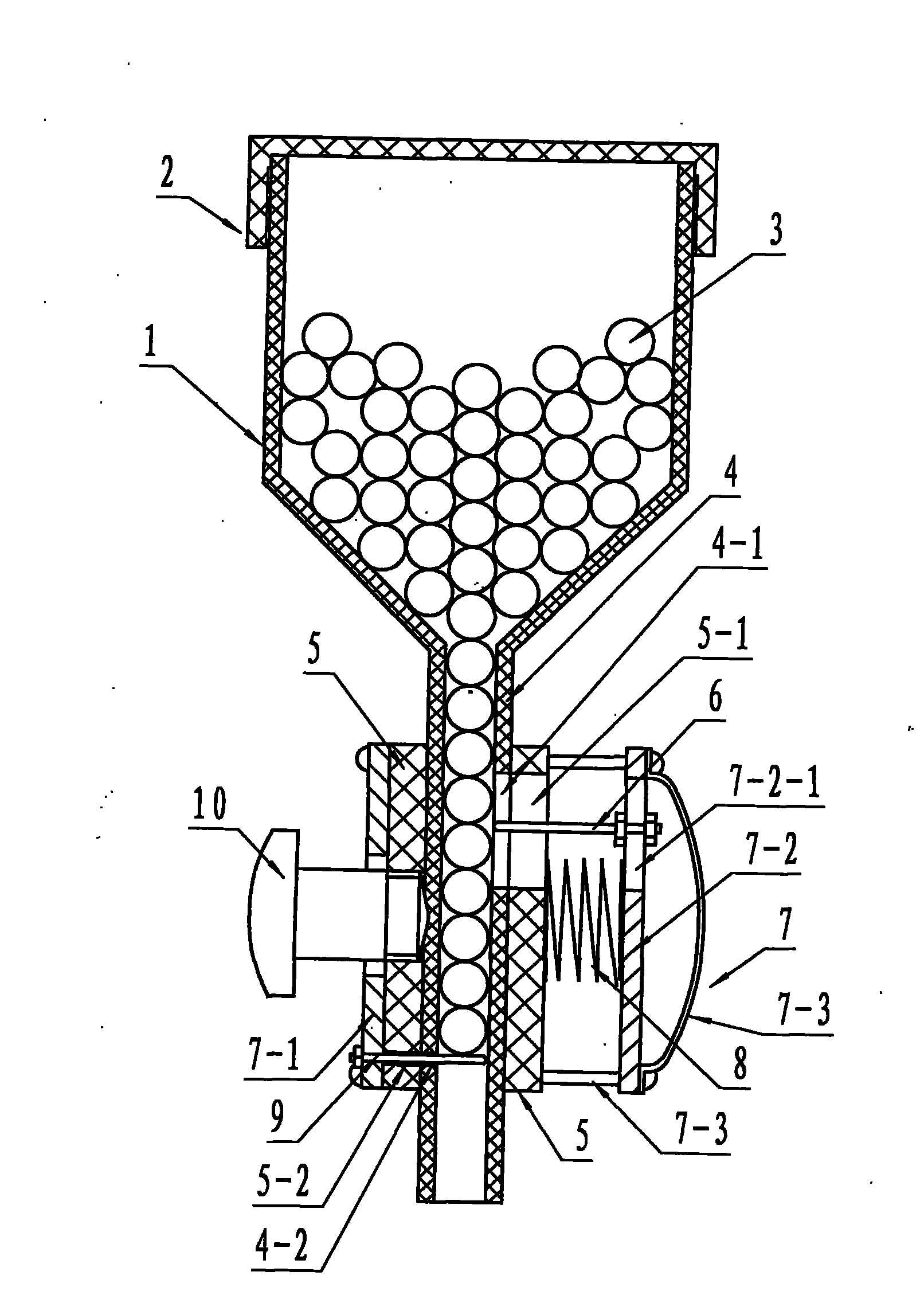

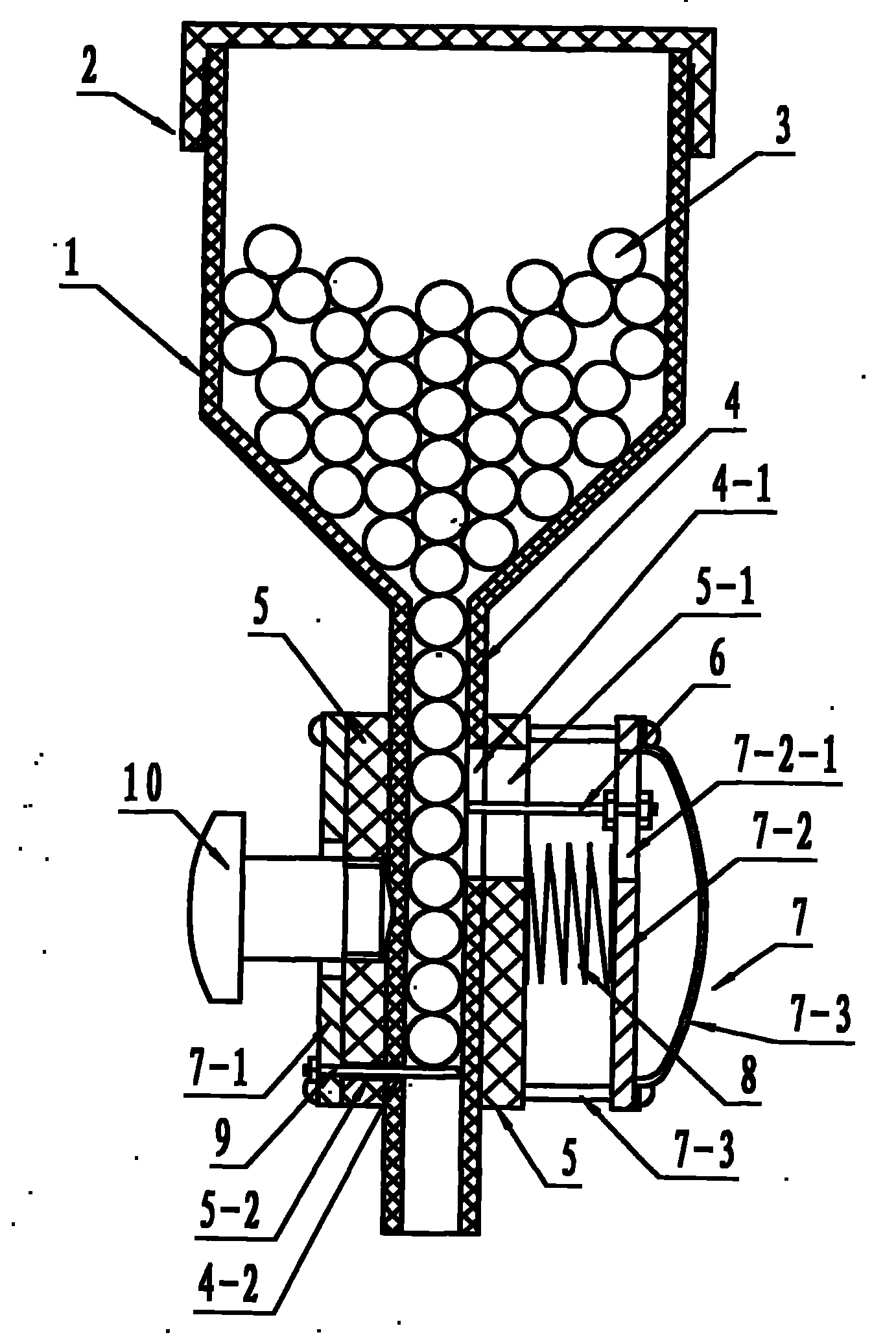

[0014] see figure 1 , Quantitative bead dropper is used to quantitatively inject balls into the tubular bearing sleeve. The quantitative bead dropper includes a ball bucket 1 , a bead guide tube 4 , a deck 5 , an infusion stand 7 and a return spring 8 . Balls are filled in the ball bucket, and a block cap 2 is arranged on the top of the ball bucket. The guide bead tube is communicated with the lower opening of the ball bucket, the inner diameter of the guide bead tube matches the outer diameter of the bearing ball, the middle part of the guide bead tube is inserted in the deck 5, and the deck and the guide bead tube are fixed by the deck fixing screw 10. The upper valve port 4-1 and the lower valve port 4-2 are respectively arranged on both sides of the guide bead tube, and the upper valve stem hole 5-1 and the lower valve stem corresponding to the positions of the upper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com