Thin film, shell with decorative pattern and method for manufacturing same

A manufacturing method and film technology are applied in the field of shells and films with decorative patterns, which can solve the problems of insufficient stereoscopic visual effect and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

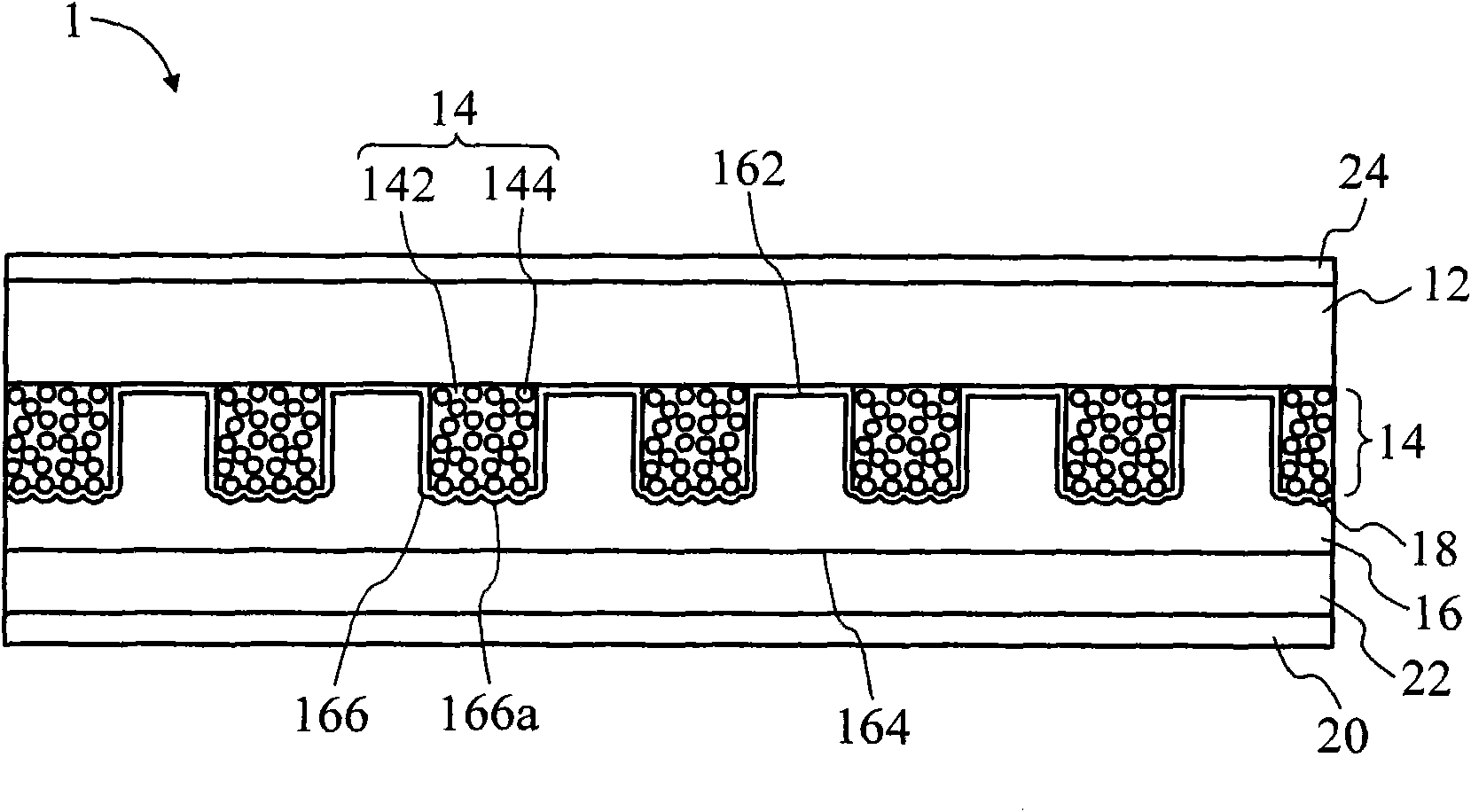

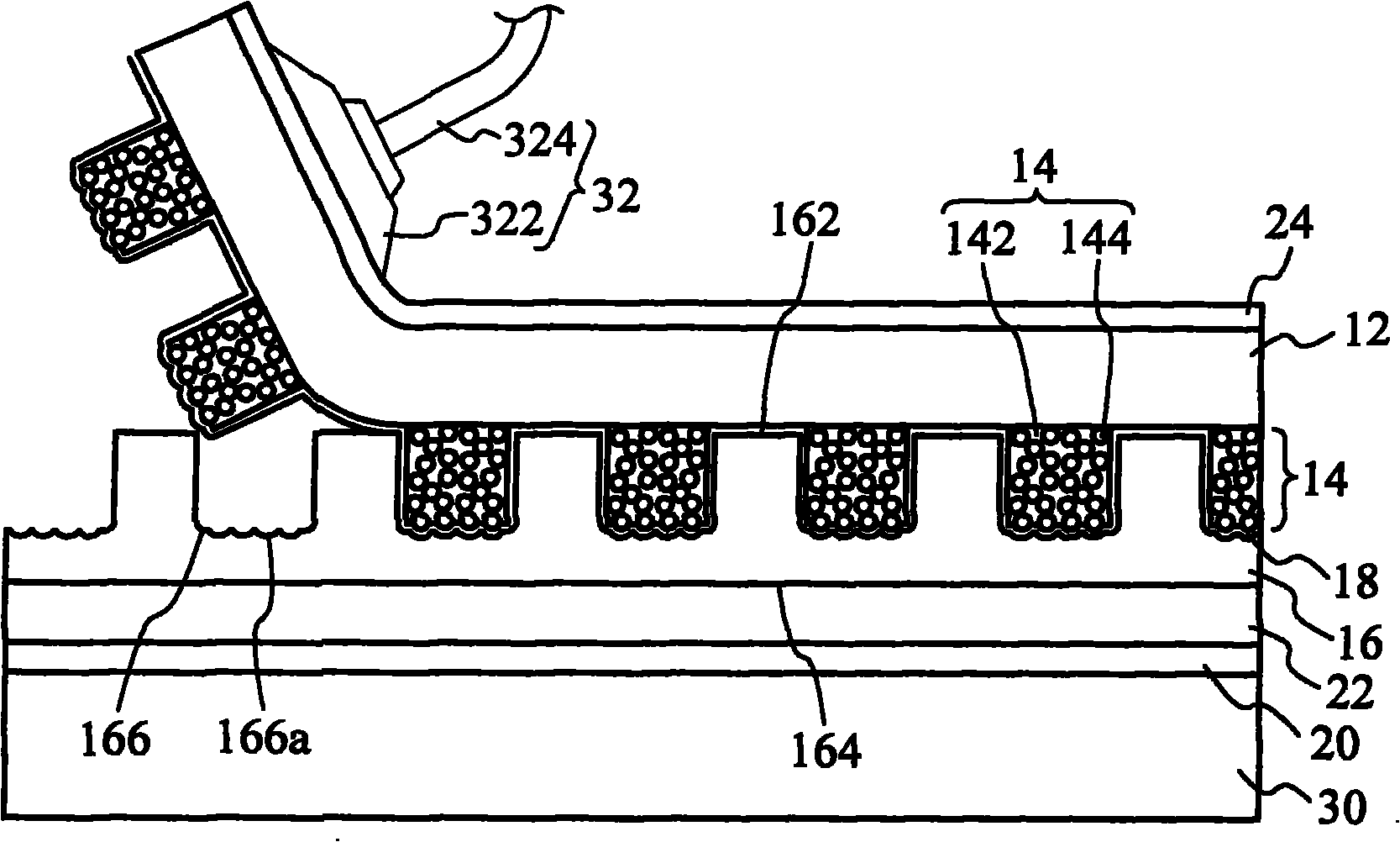

[0047] see figure 1 , figure 1 A schematic cross-sectional view of a film 1 according to a specific embodiment of the present invention is shown. The film 1 includes a carrier film 12 , a structural layer 14 , a hardening layer 16 , a release layer 18 , an adhesive layer 20 , a decoration layer 22 and an antistatic layer 24 . The carrier film 12 is used to carry the multi-layer structure, and its material can be selected from polyester (Polyester, PET), polycarbonate (Polycarbonate, PC), cast polypropylene (Casted Polypropylene, CPP) or other materials that can be used to make a multi-layer structure. The thickness of the material of the structural-functional film may be between 25 microns and 200 microns, and a preferred thickness may be about 20 microns; however, the present invention is not limited thereto.

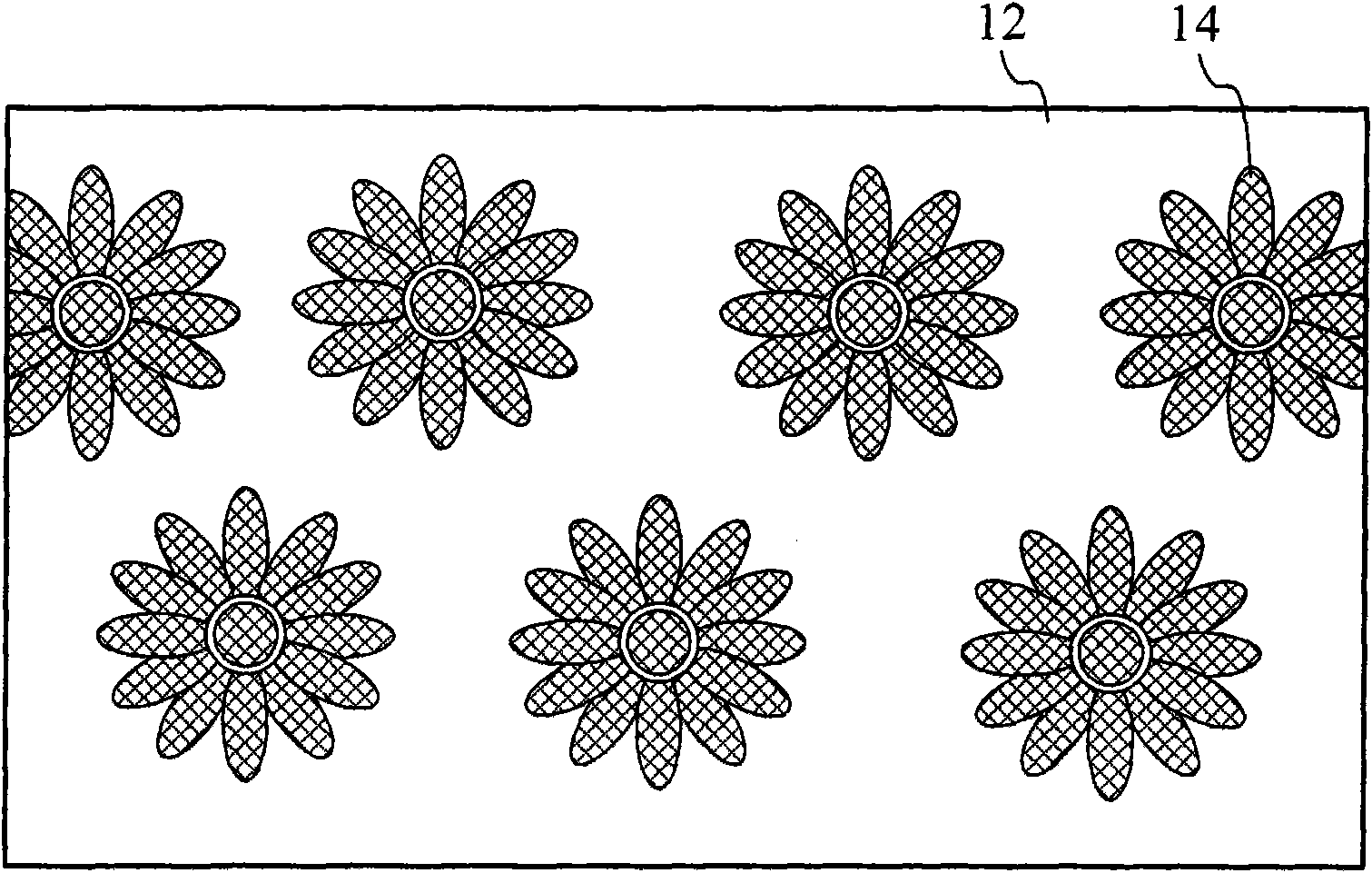

[0048] The structural layer 14 is formed on the carrier film 12 and has a first pattern. The material of the structural layer 14 mainly includes a resin 142 and a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com