Method for preprocessing neopentyl glycol industrial wastewater by catalytic oxidation

A technology for the production of neopentyl glycol and wastewater, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, molecular sieve catalysts, etc., to achieve the effects of reducing organic loads, low cost, and broad prospects for engineering applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

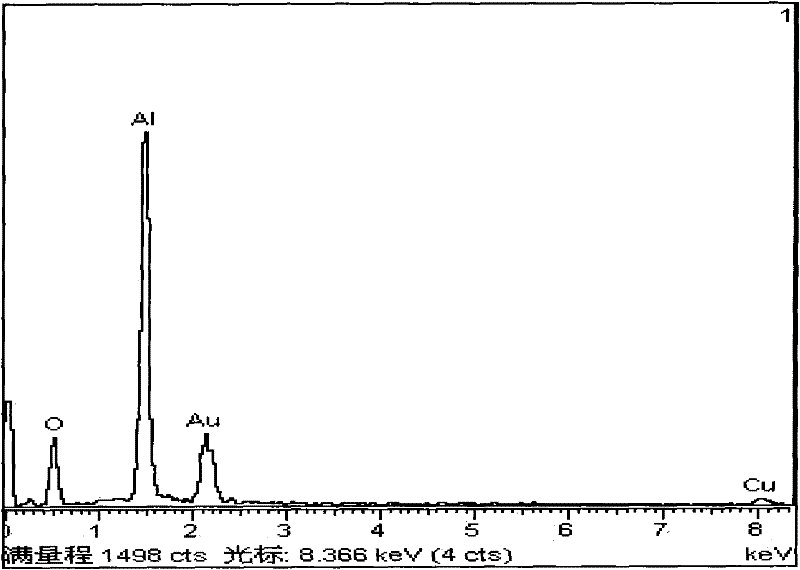

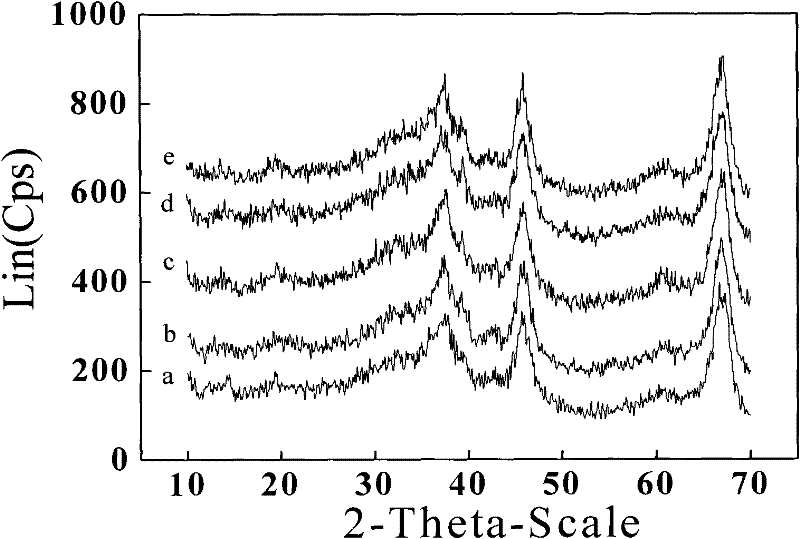

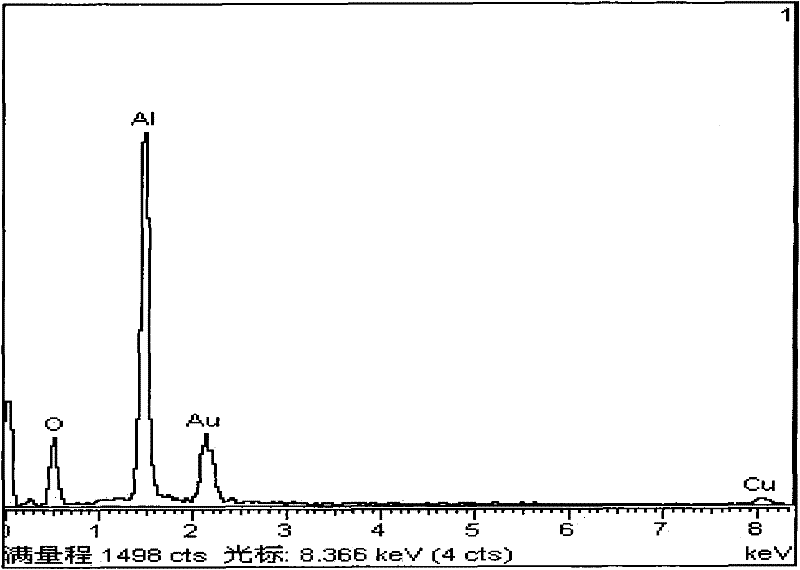

[0021] Take 2.0 grams of copper nitrate to make a copper nitrate solution with a mass fraction of 2.0%; then weigh 20.0 grams of γ-Al 2 o 3 Added to 2.0% copper nitrate solution, the catalyst active component, that is, copper nitrate, was evenly distributed in the γ-Al by equal volume impregnation method. 2 o 3 The catalyst was impregnated for 2 hours, dried at a constant temperature of 100°C for 8 hours, and calcined at 300°C for 3 hours.

Embodiment 2

[0023] Take 1.0 gram of ferric nitrate and make it into a 1.0% ferric nitrate solution; then weigh 20.0 grams of γ-Al 2 o 3 Added to 1.0% ferric nitrate solution, the active component of the catalyst, namely copper nitrate, was evenly distributed in the γ-Al 2 o 3 The catalyst was soaked for 1 hour, then dried at 80°C for 9 hours, and calcined at 200°C for 4 hours.

Embodiment 3

[0025] Take 6.0 grams of copper nitrate to make a copper nitrate solution with a mass fraction of 6.0%; then weigh 20.0 grams of γ-Al 2 o 3 Added to 6.0% copper nitrate solution, the catalyst active component, that is, copper nitrate, was evenly distributed in the γ-Al 2 o 3 The catalyst was impregnated for 2 hours, dried at a constant temperature of 100°C for 8 hours, and calcined at 300°C for 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com