Sweeping mechanism of road sweeper

A cleaning mechanism and road cleaning technology, which is applied in road surface cleaning, cleaning methods, construction, etc., can solve the problem that garbage cannot be smoothly sent into the main rolling cleaning chamber, and achieve the goals of reducing secondary pollution, convenient maintenance and high cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

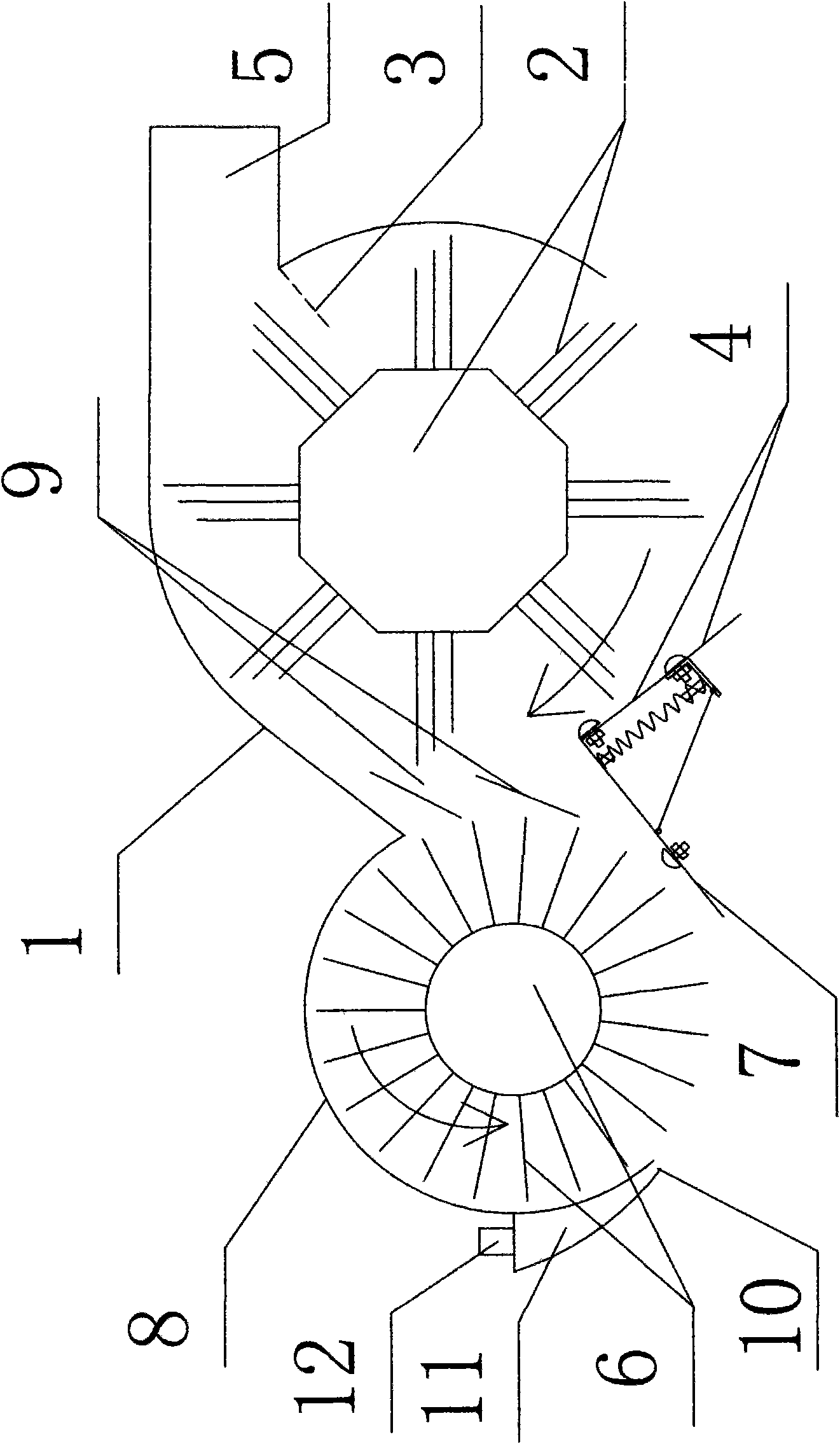

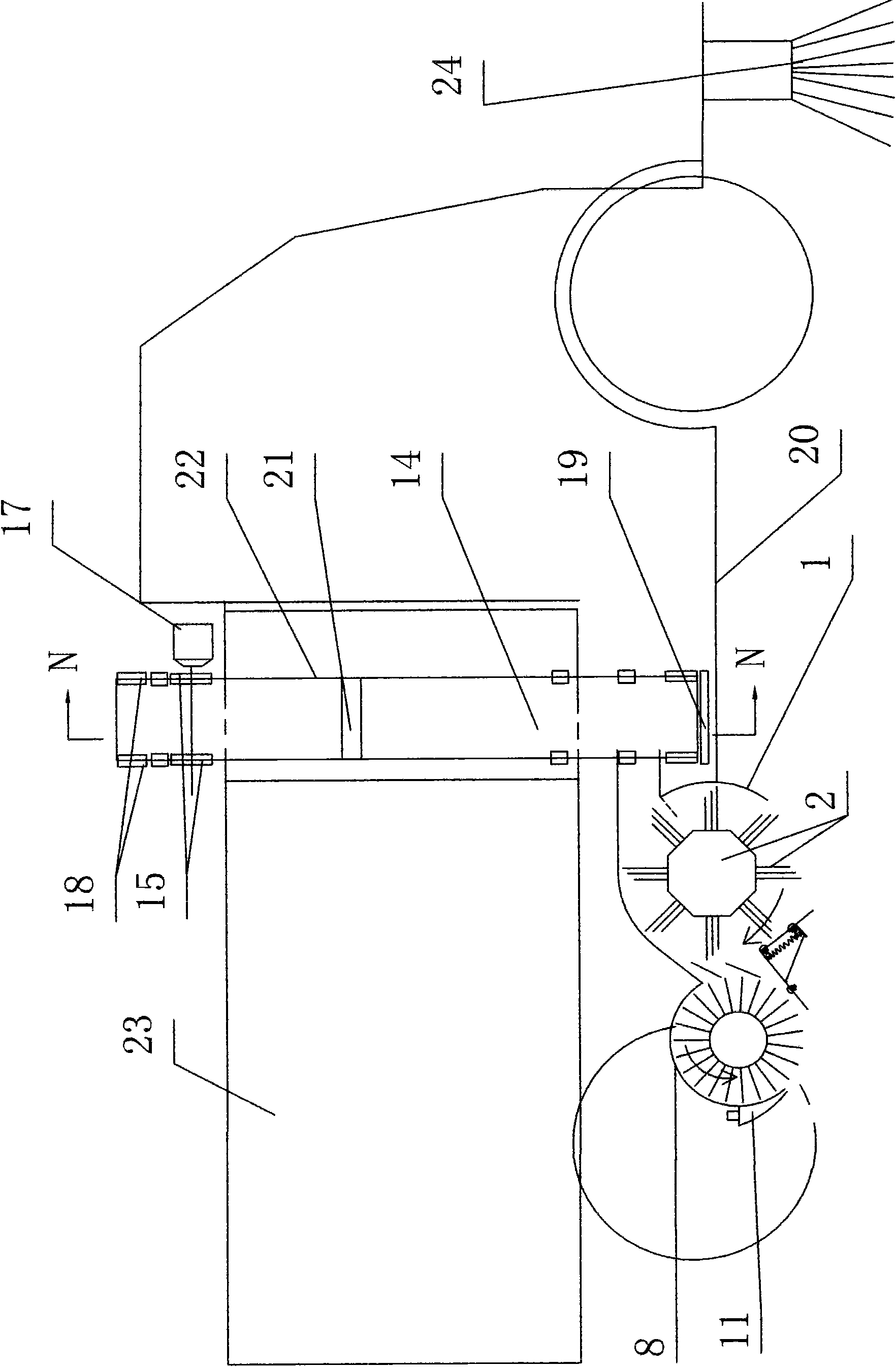

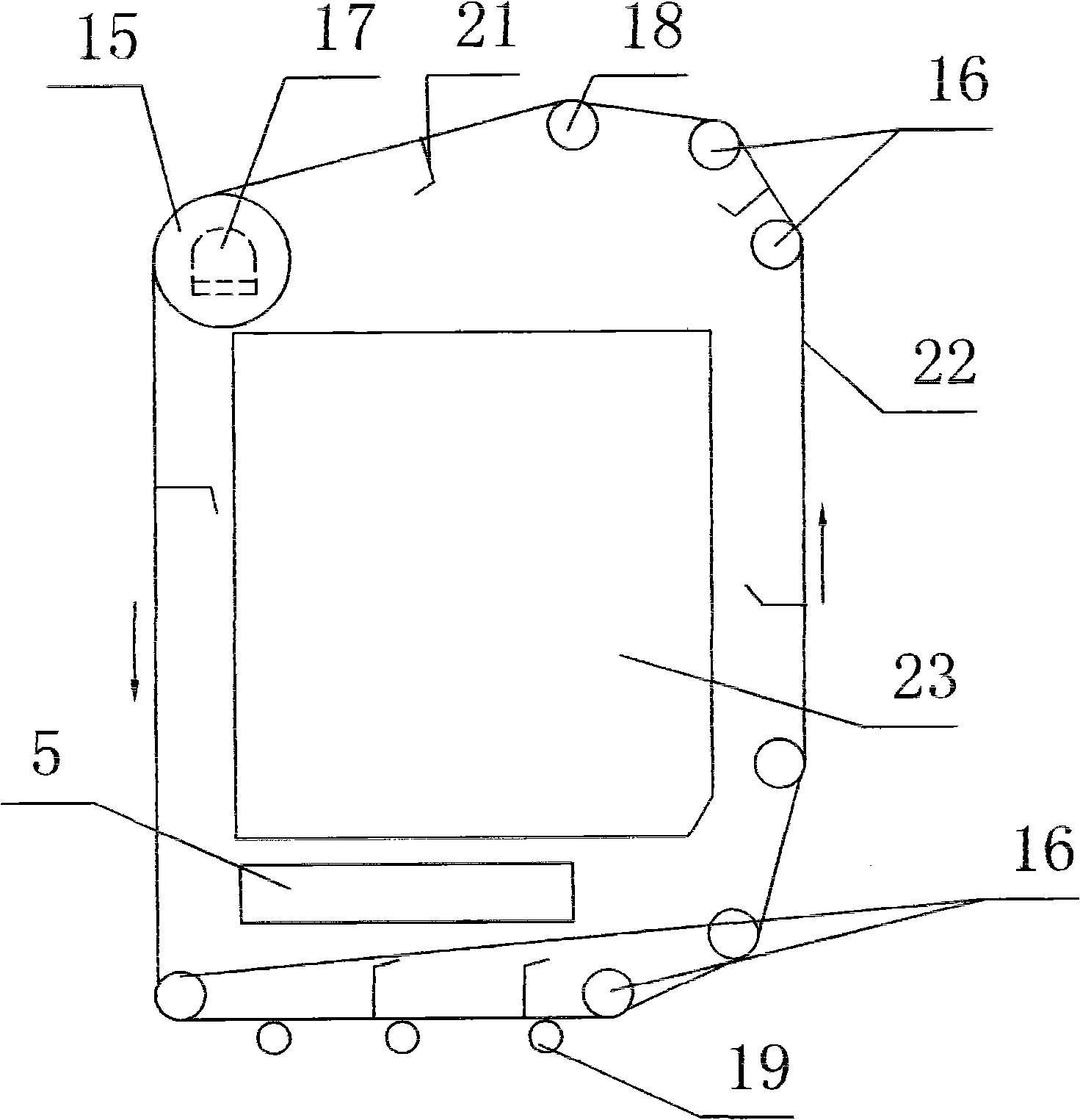

[0028] Such as figure 1 , figure 2 , diagram 2-1 , Figure 2-2 , image 3 , Figure 4 , Figure 5 , Figure 5-1 , Figure 6 , Figure 7 , Figure 7-1 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 Shown, be the sweeping mechanism of road cleaning vehicle of the present invention, it is by a main rolling sweep cover 1, main rolling sweep 2, a secondary rolling sweep 6, secondary rolling sweeping cover 8, comb type dust shield, elastic dust guide plate, The transmission system and other components (see the structural principle for details) figure 1). Its structural principle is that the cleaning mechanism of the present invention is installed in the middle section of the bottom of the chassis 20, and the cleaning mechanism of the present invention can be moved up and down on the car body by manipulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com