Bearing structure of three-dimensional garage with energy-consumption truss lateral-resistance form vertical-lifting type high-rise steel structure

A three-dimensional garage, vertical lifting technology, applied in the direction of building components, building types, building structures, etc., can solve the problems of large lateral displacement, low lateral stiffness, and prolong the construction period, so as to increase the seismic energy consumption capacity, reduce the The effect of destruction and construction convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

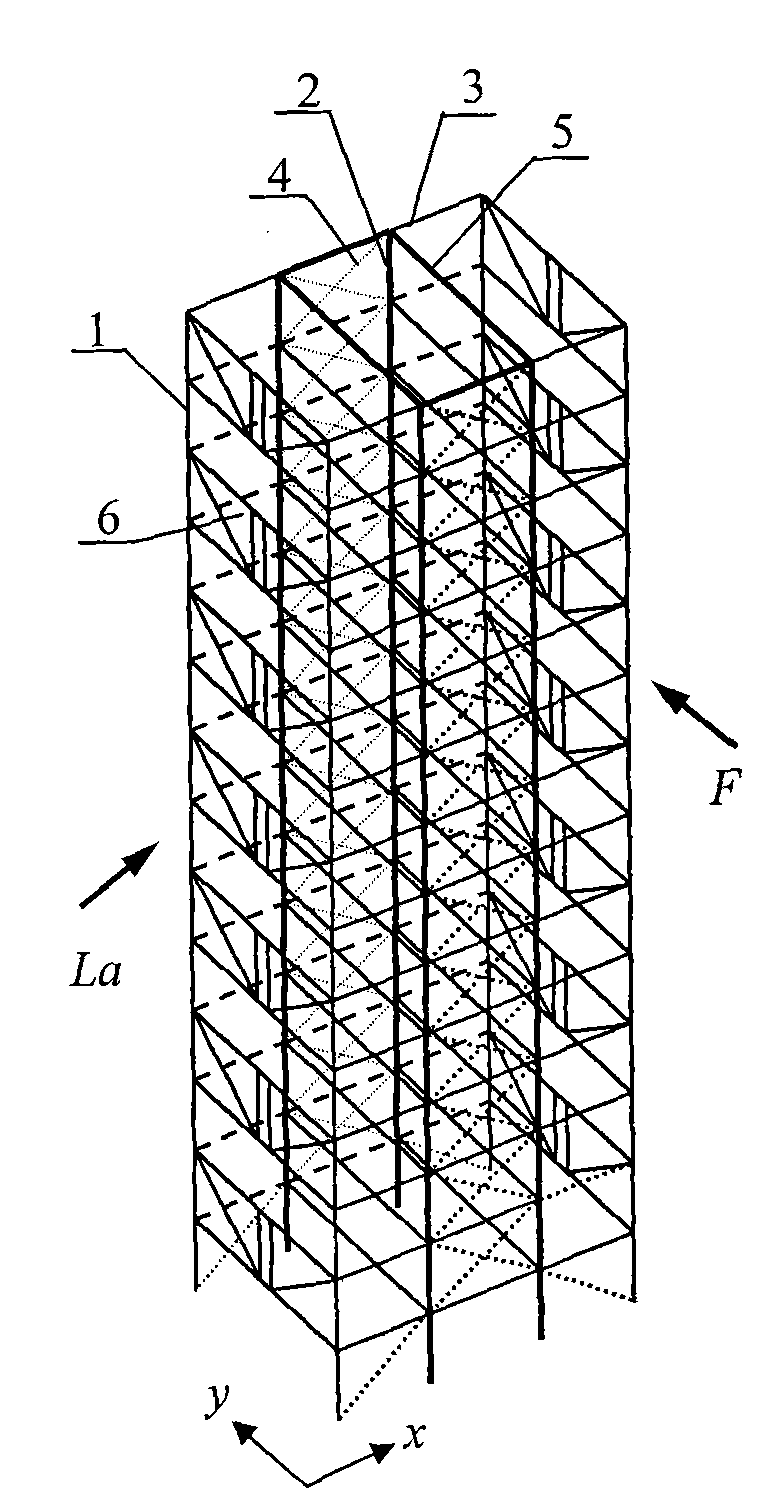

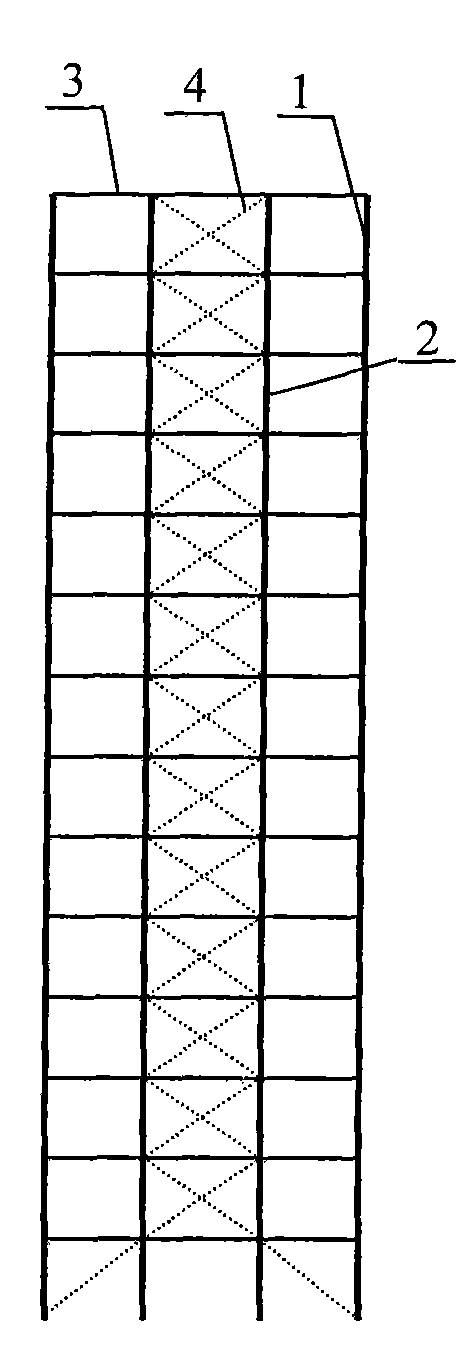

[0016] In this embodiment, the vertical lifting type high-rise steel structure three-dimensional car load-bearing structure has a horizontal length S of 6 meters, a longitudinal length L of 7.8 meters, and a floor height h of 2.2 meters. ) frame beam 3, the X-shaped support 4 arranged between the front and rear facade central columns, the middle transverse (y-direction) frame beam 5 and the energy-dissipating trusses 6 on both sides, forming the middle lifting shaft I and the parking spaces on both sides II. The energy-dissipating trusses 6 arranged in the facade compartments on both sides of the structure constitute the anti-side member for the structure to bear the in-plane horizontal force.

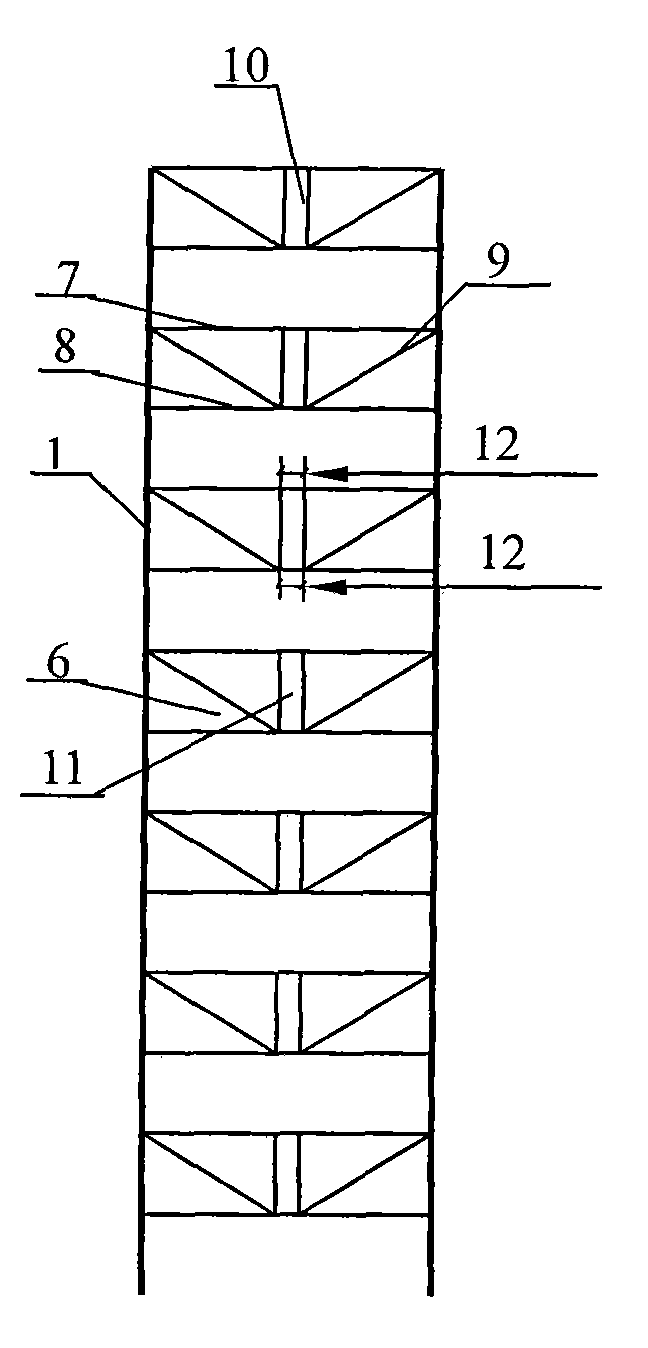

[0017] The energy-dissipating truss 6 of this embodiment is composed of an upper chord 7, a lower chord 8, two oblique webs 9 and two vertical webs 10. All the webs are symmetrically arranged, and the height of the truss is the same as the height of the structure. The truss and the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com