Wind-driven generator with rotary blades

A wind engine, rotary technology, applied to wind engines, wind turbine components, engines, etc., can solve problems such as low efficiency and achieve high wind energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

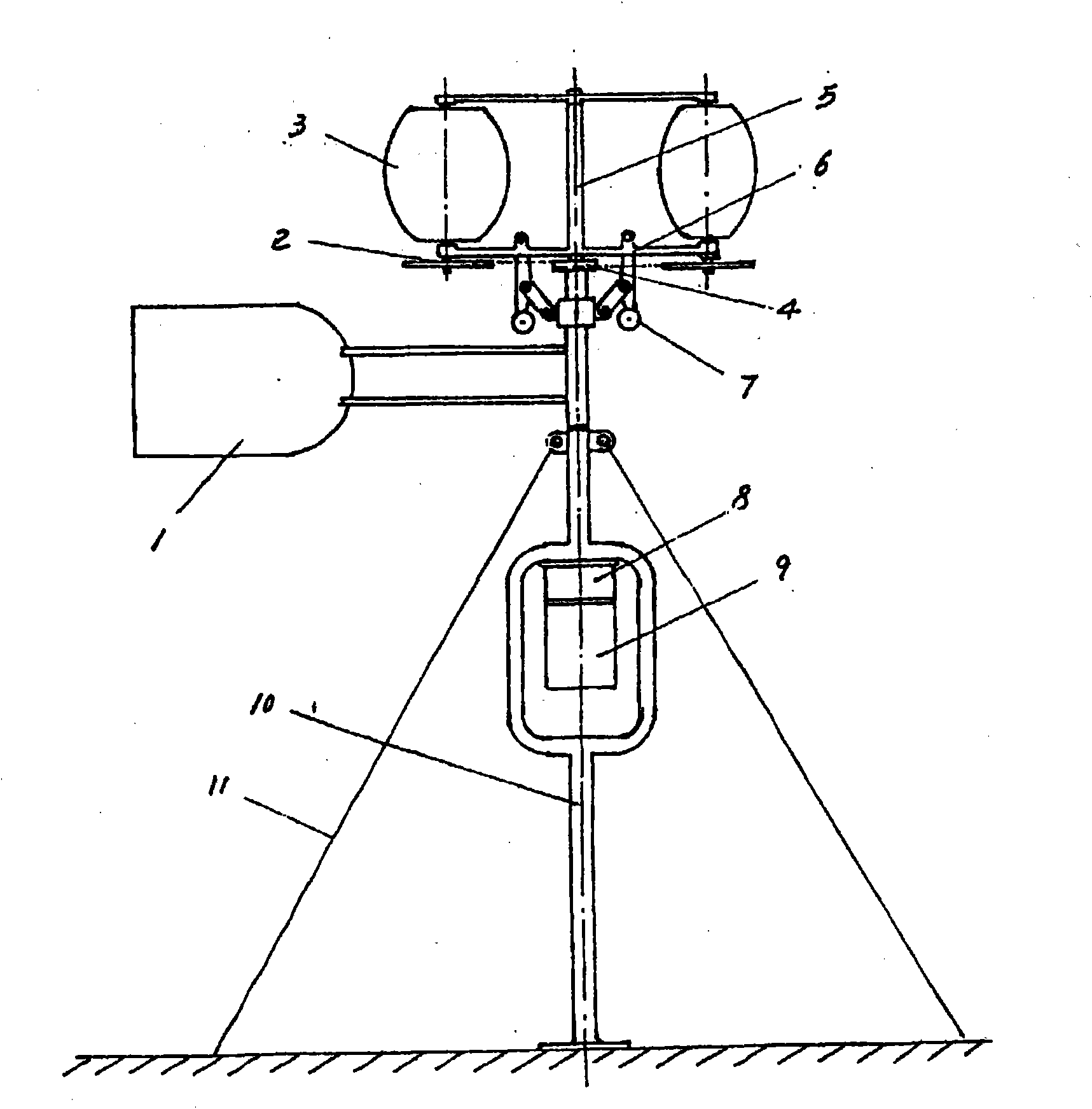

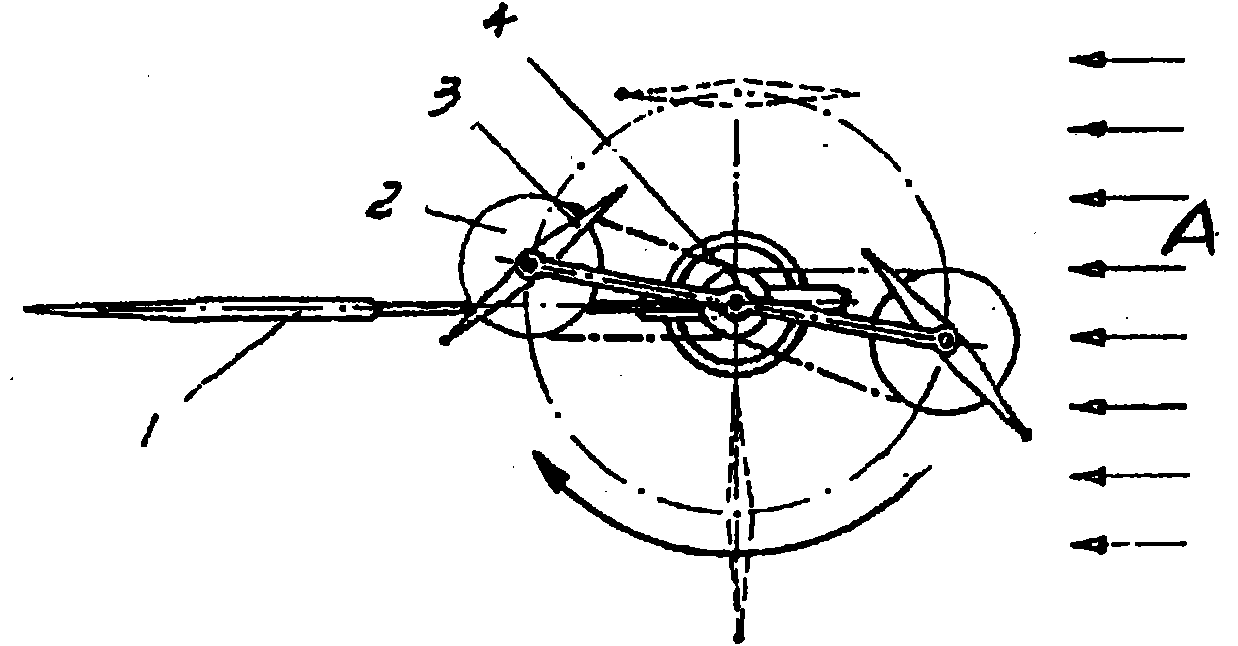

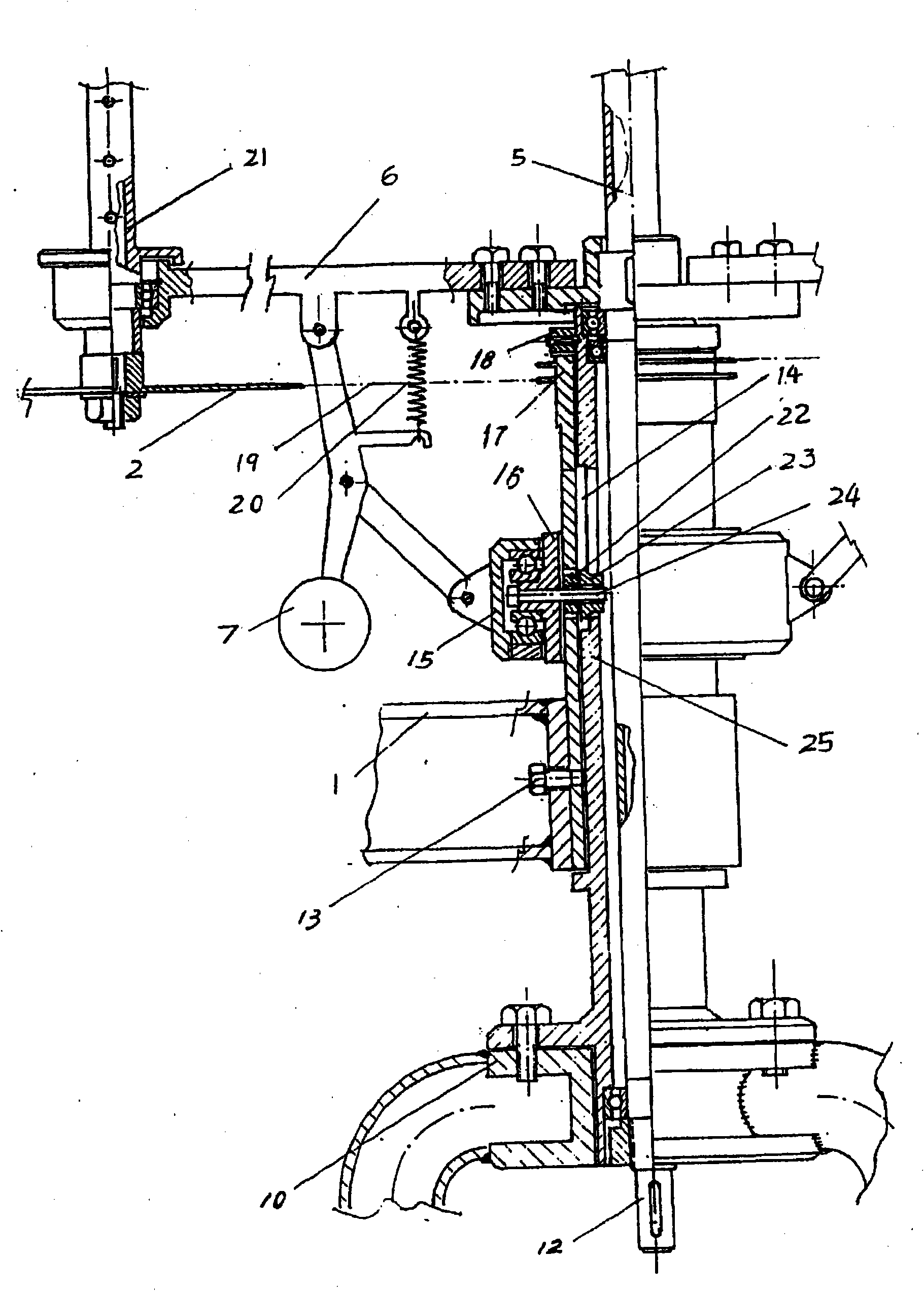

[0011] Example 1, see figure 1 , figure 2 , image 3 The wind wheel of the blade wind power engine is vertically arranged, the planetary wheel and the center wheel are sprockets and are driven by a chain, the output shaft 12 at the bottom of the wind wheel shaft drives the generator 9 to generate electricity through the speed increasing mechanism 8, the speed increasing mechanism and the generator are installed In the frame 10, the frame 10 is installed on the foundation and tightened by the bell rope 11. The frame is equipped with a bracket hollow shaft 25. The lower part of the bracket hollow shaft is equipped with a wind rudder 1 and is tightened with screws 13. The bracket hollow shaft The middle part is equipped with a sliding sleeve 16 rotating sleeve us, a thrust bearing is installed between the sliding sleeve and the rotating sleeve, the upper part of the hollow shaft of the bracket is equipped with a backstop 18 that limits the axial position of the sleeve; There i...

Embodiment 2

[0012] Example 2, see Figure 4 , the wind wheel is set vertically, the planetary wheel uses bevel gear 27, the center wheel uses bevel gear 26, and the bevel gear is coupled with the bevel gear at the outer end of the shaft 28, the bevel gear at the inner end of the shaft 28 is coupled with the bevel gear 26, and the bevel gear 26 is contained on the sleeve 17, constitutes planetary gear drive.

Embodiment 3

[0013] Embodiment 3, see Fig. 6, wind wheel horizontal arrangement, bevel gear 27 is housed on the axle of blade 3, and bevel gear 27 is coaxial with the cylindrical gear on the shaft 28, and this cylindrical gear and gear 29 (central wheel) gnaw house, and gear 29 are contained on the sleeve 17.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap