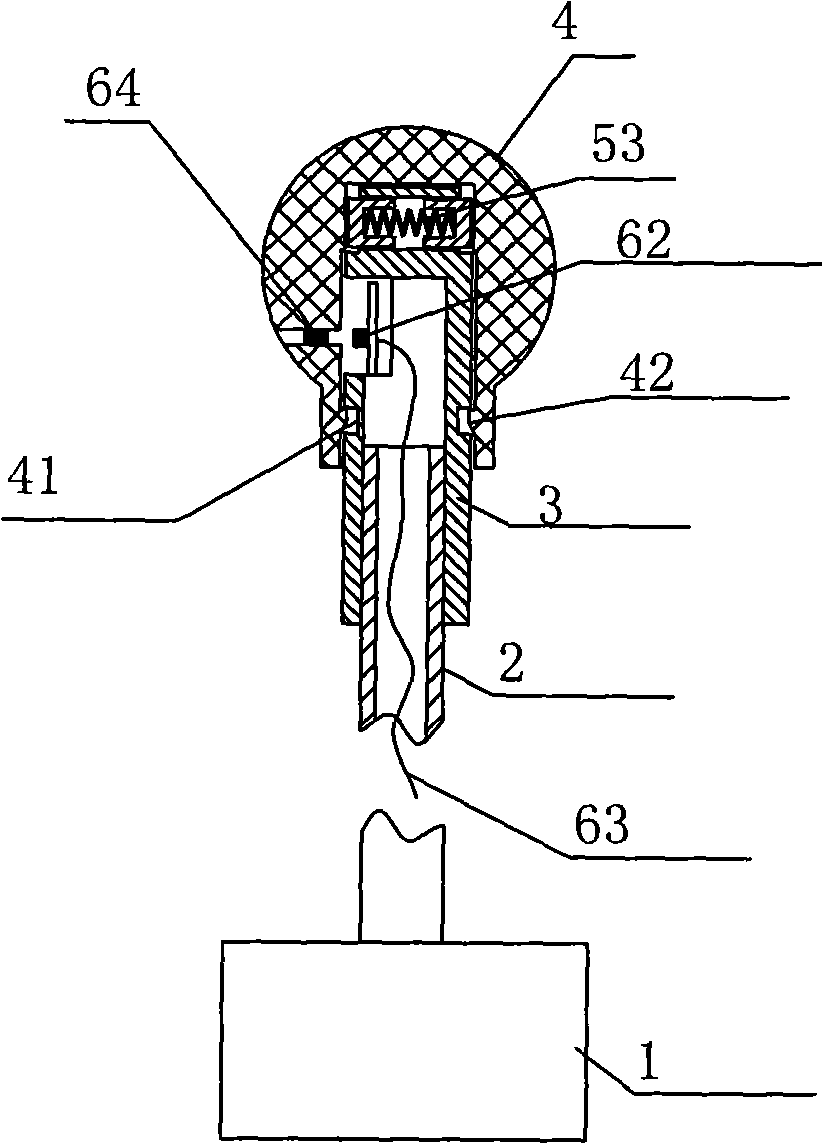

Control handle with rotatable handle ball

A technology for manipulating handles and handles, which is used in transmission control, elements with teeth, belts/chains/gears, etc., can solve the problems of inability to meet control requirements, poor reliability, and inconvenient use of control handles, and achieve long life. , Easy to operate, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

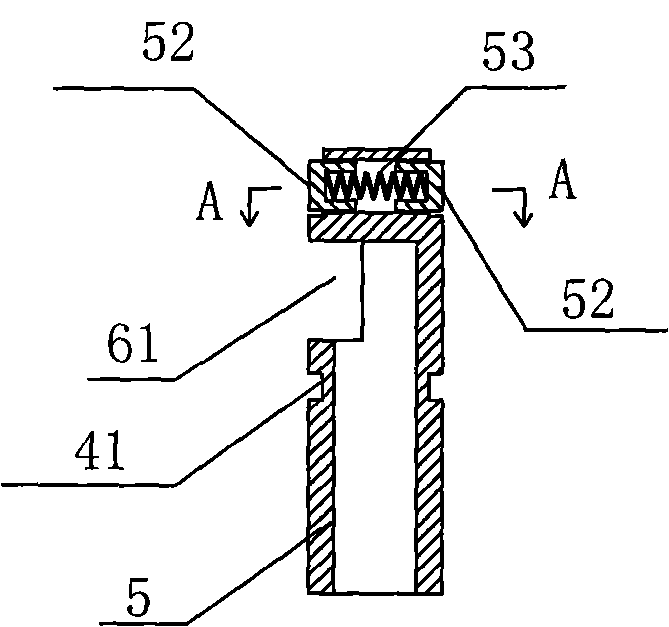

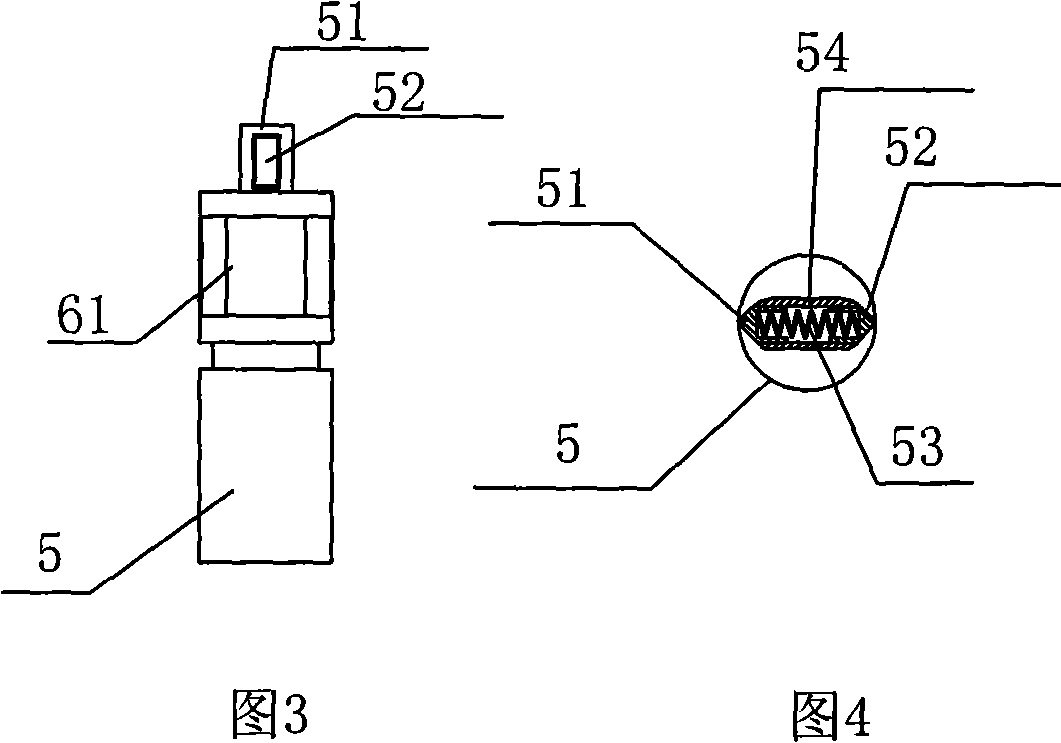

[0025] When the ball head of the handle is rotated, the magnet embedded in the upper shell rotates at the same time, and the Hall element in the handle sleeve will output the corresponding gear signal. The proper position of the handle ball (or on the instrument panel) has an indication of the rotational position of the handle ball. Because the inner end surface of the sleeve hole of the handle ball head has six gear slots and two limit ribs, the handle ball head can only rotate 150° and have only three stop positions, such as Figure 7 , Figure 8 and Figure 9 shown. The handle ball head and the handle sleeve pipe are engaged with the locking block by the locking block, so the handle ball head can only rotate axially relative to the handle sleeve pipe, but cannot move up and down. The positioning slider pushed out by the spring in the slider limit hole on the upper part of the handle sleeve can be pushed back into the slider limit hole by the smooth connection of the adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com