High-efficiency ammonia-water absorption-type refrigeration device

An absorption refrigeration, ammonia water technology, applied in refrigerators, refrigeration components, adsorption machines, etc., can solve problems such as system efficiency decline, and achieve the effect of improving the refrigeration coefficient, increasing the absorption pressure, and simplifying the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

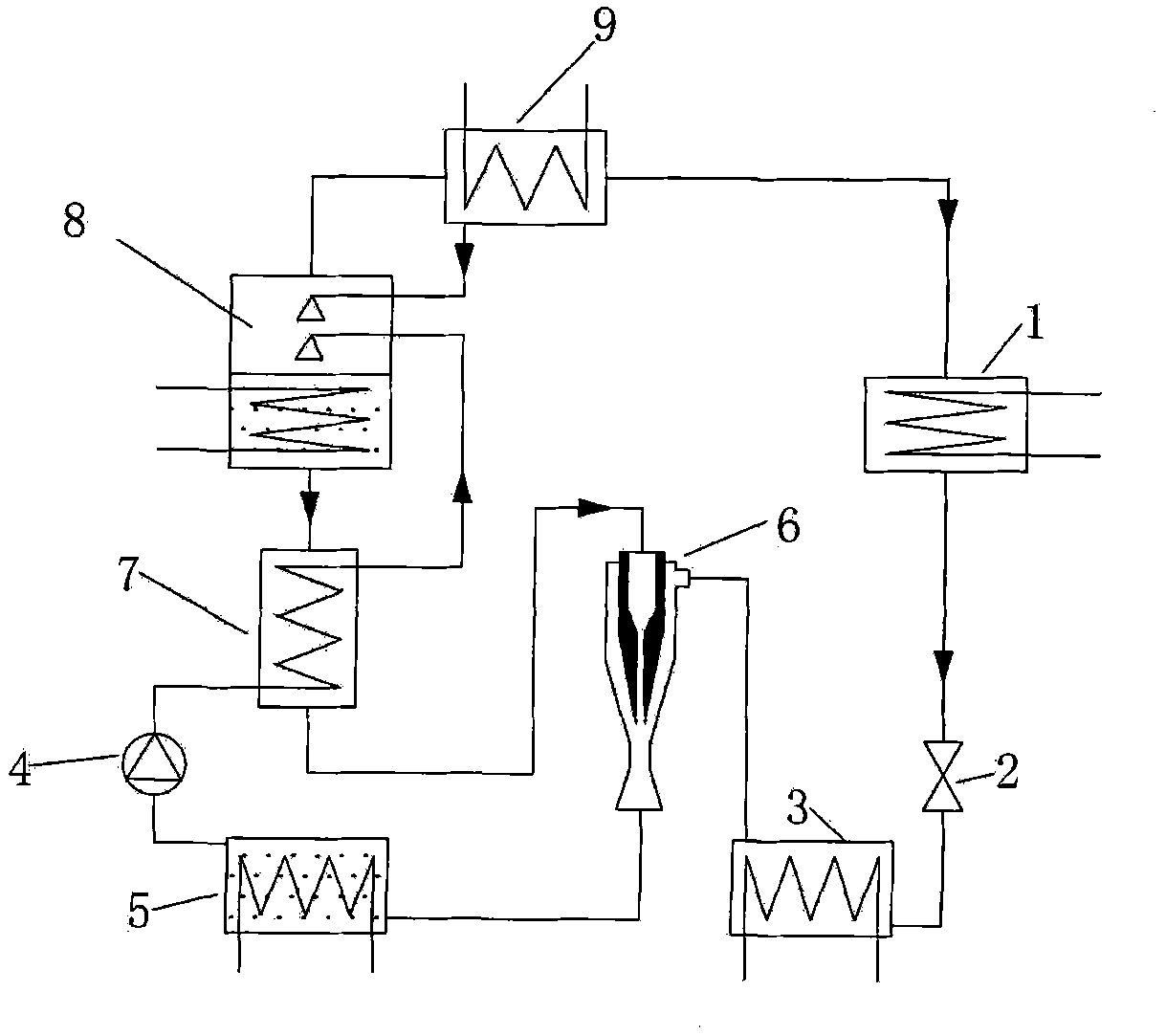

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

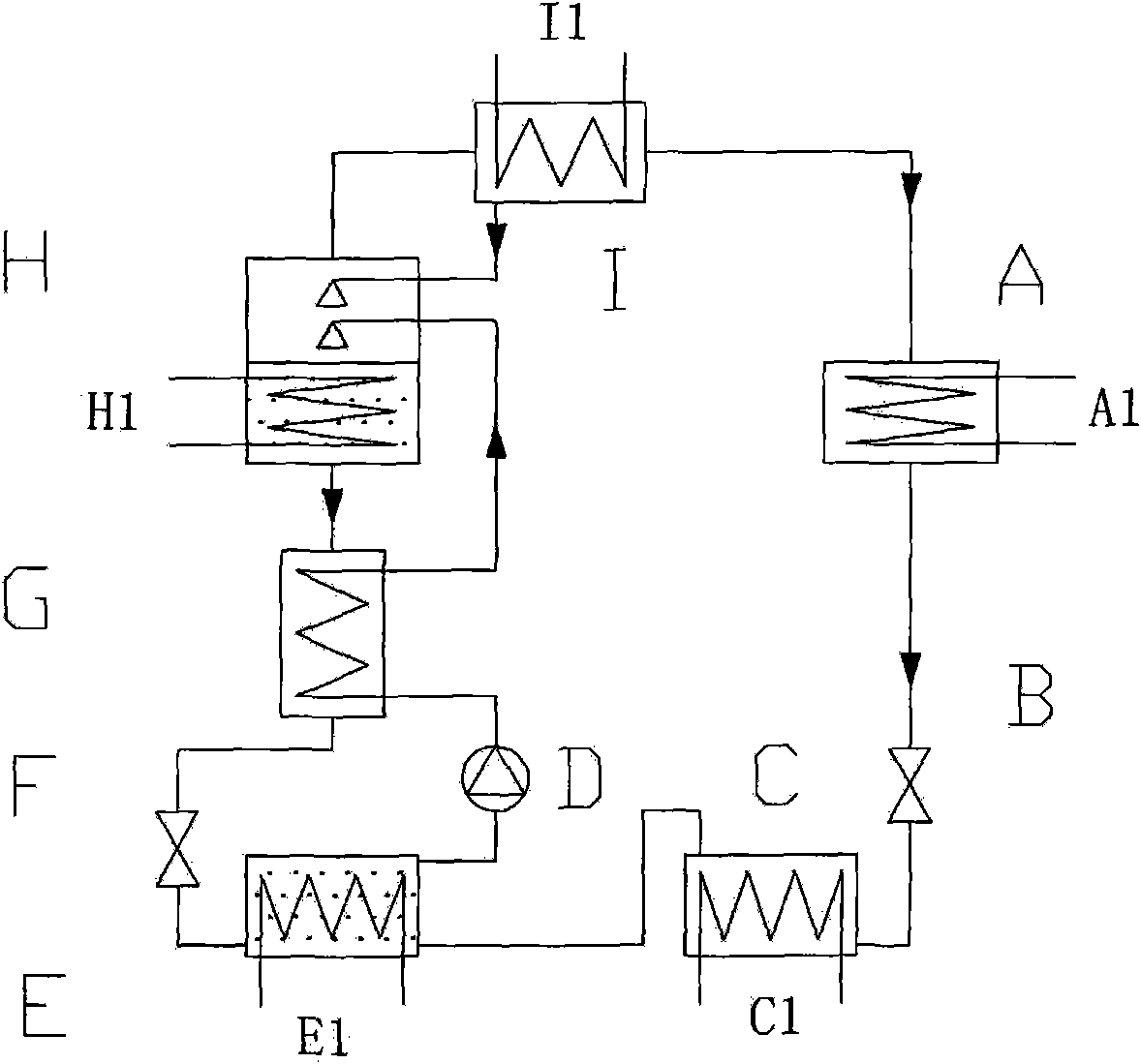

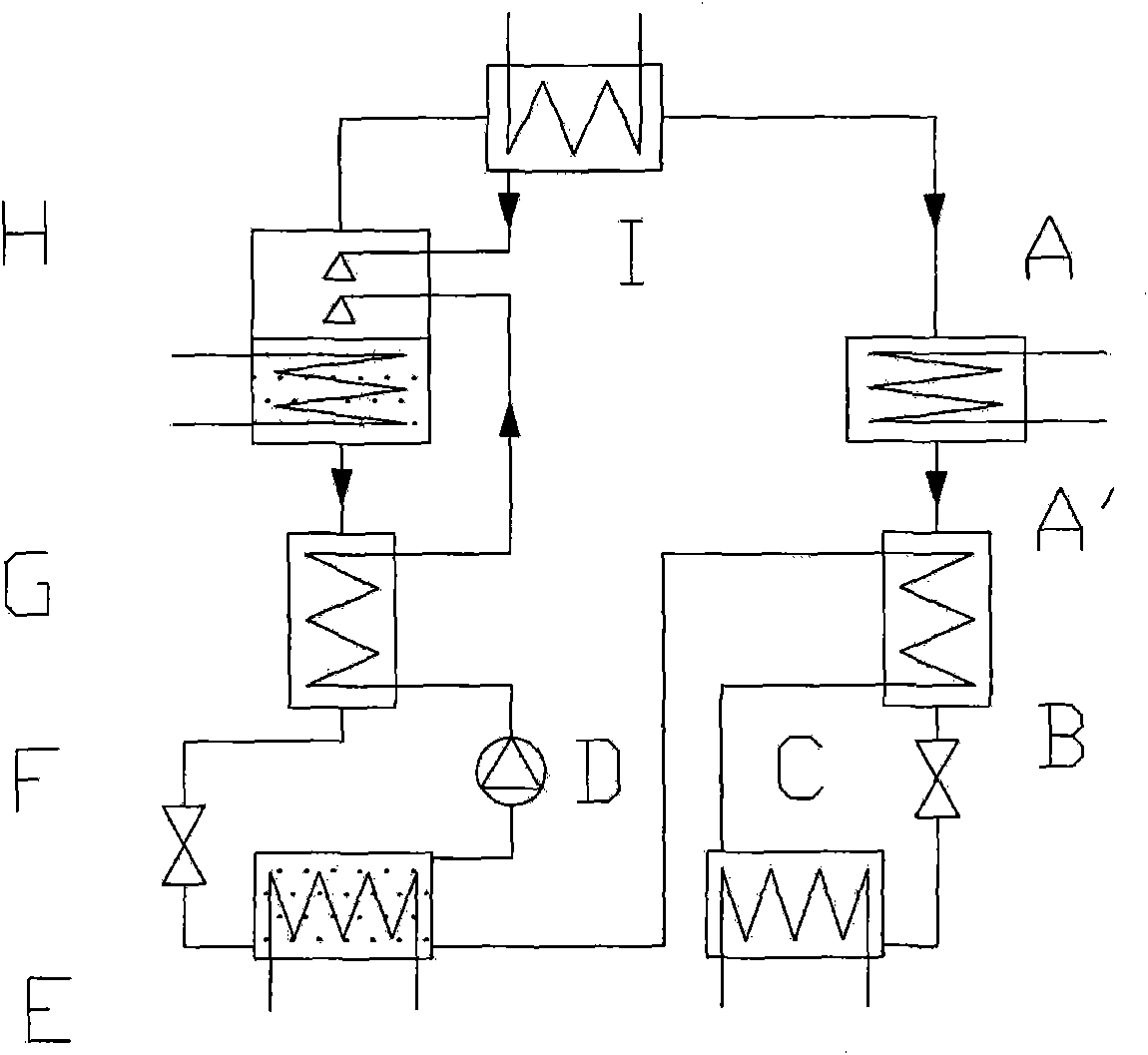

[0026] In order to solve the problems existing in the prior art, the present invention provides a new type of ammonia water absorption refrigeration system. The system uses ejectors to replace the original dilute solution throttling device, and the dilute solution from the solution heat exchanger is used as the ejector. The working fluid, the ammonia vapor from the evaporator is the injection fluid; the dilute solution and the ammonia vapor are mixed and pressurized in the ejector and then injected into the absorber. The ejector recovers the energy in the process of depressurizing the dilute solution to increase the absorption pressure of the absorber. Under the same conditions as the cooling water temperature and the heat source temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com