Fluid boundary control-based quantitative measurement method for fluid slippage on super-hydrophobic surface

A super-hydrophobic surface and boundary control technology, which is applied in the direction of measuring devices, surface/boundary effects, instruments, etc., can solve the problems of slip length test deviation difference, uneven cross section, and no improvement method is given, so as to improve the test Accuracy, the effect of ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

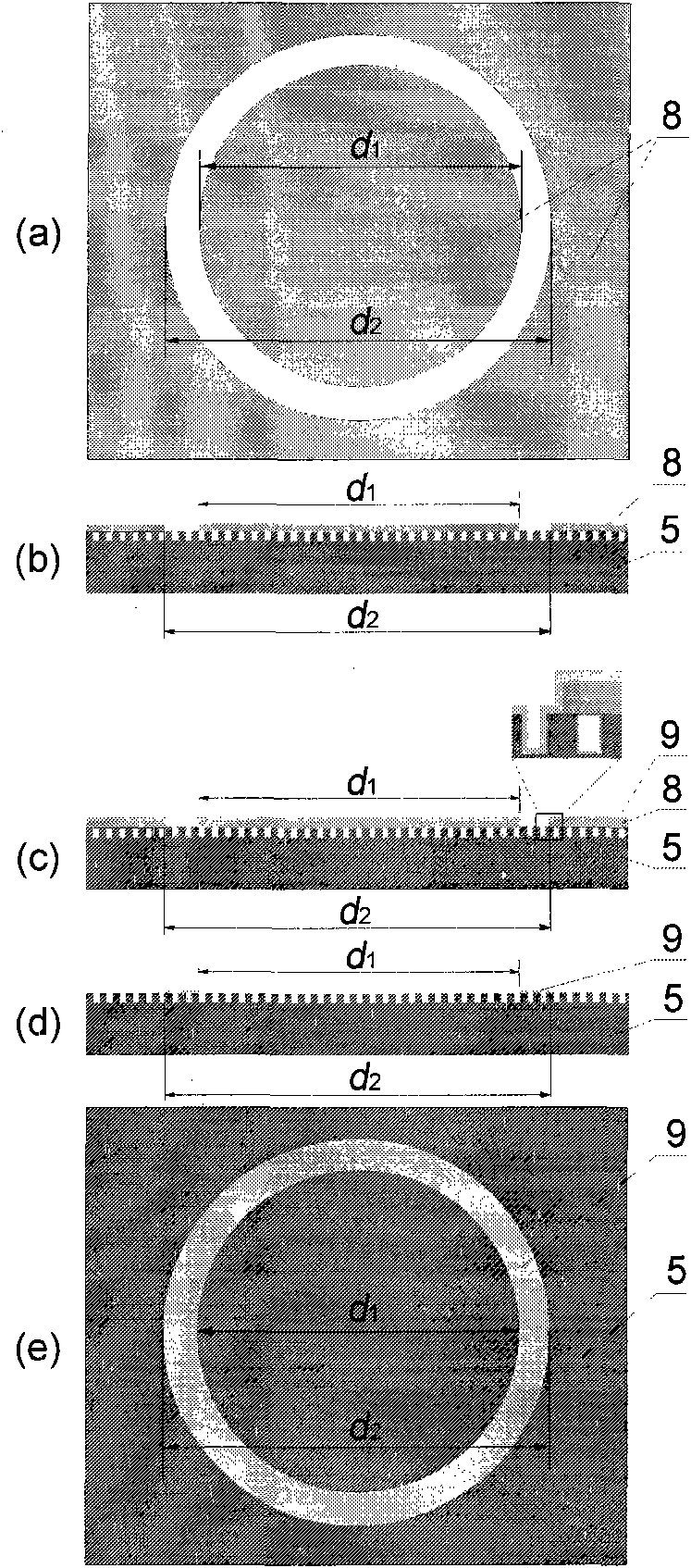

[0032] Embodiment one (using flat fixture to measure, as image 3 , Figure 4 )

[0033] image 3 Schematic diagram of the process of treating the prepared superhydrophobic surface. First process two masks 8, the diameter d of the circular mask 1 than fixture d 2 The diameter is small, the effect is better when the diameter is 1-3mm smaller, the aperture d of the circular hole mask 2 with fixture diameter d 2 Equal, no special requirements for external shape, such as image 3 (a) shown. Cover the prepared mask 8 on the superhydrophobic surface 5, such as image 3 (b) shown. Hydrophilic treatment is carried out on the superhydrophobic surface 5 covered with the mask 8, generally by spraying gold or spraying hydrophilic metal materials, and other hydrophilic coating treatment methods can also be used to perform superhydrophobic treatment after hydrophilic coating treatment. There is an extremely thin coating 9 on the surface 5 and the mask surface 8, such as image 3 ...

Embodiment 2

[0036] Embodiment two (use cone-plate fixture to measure, as image 3 , Figure 5 )

[0037] The difference from the first embodiment is that the cone-plate fixture 4 is used for measurement, and the calculation formula for the fluid slip length used is the calculation formula (4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com