Water-resistant power cable

A power cable and water-blocking technology, which is applied to power cables with shielding layers/conductive layers, insulated cables, cables, etc., can solve problems such as cable damage, steel strip, copper strip metal corrosion, and insulation performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

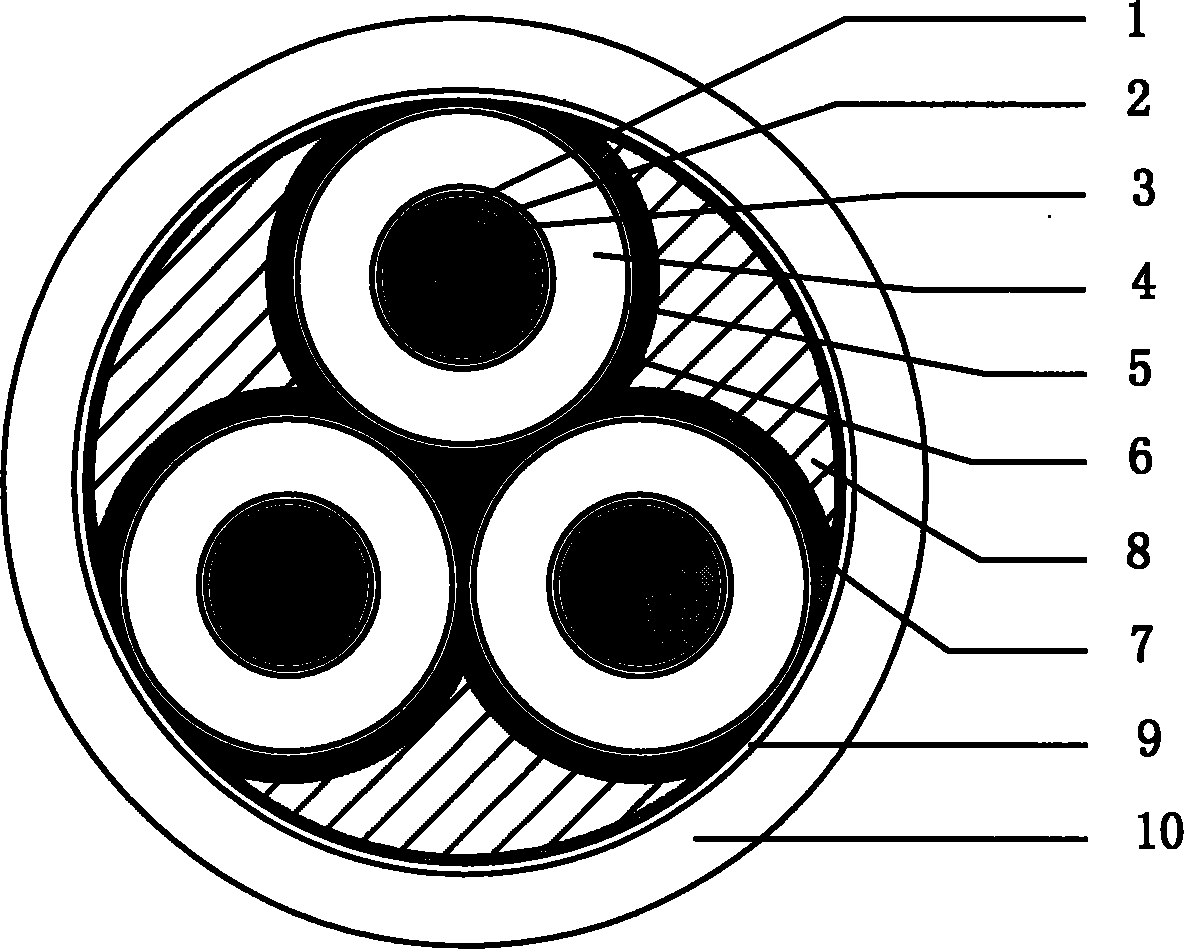

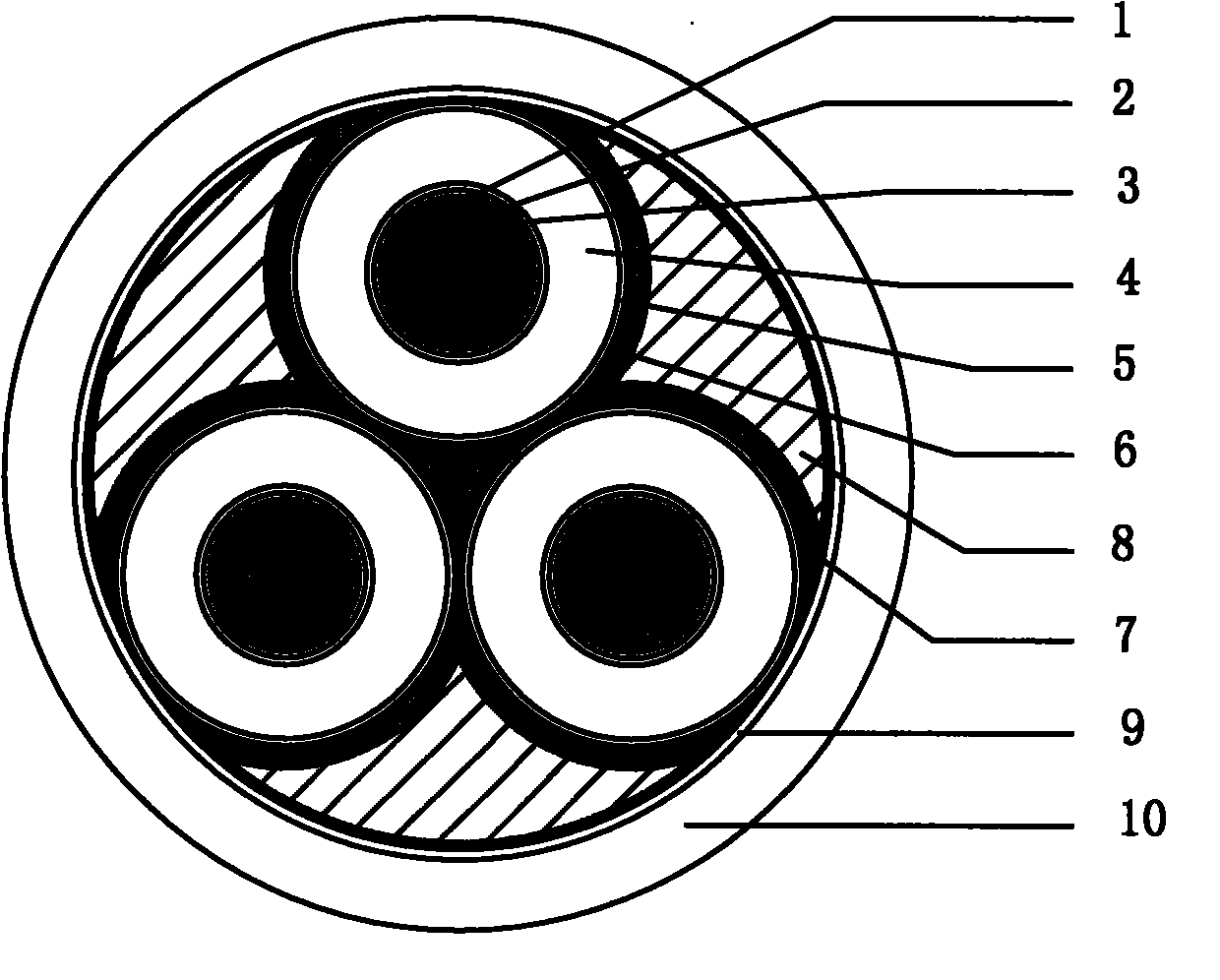

[0009] Such as figure 1 As shown, a water-blocking power cable mainly includes a wire core, a wire core water-blocking layer 7, a wrapping tape 9 and an outer sheath 10; wherein the wire core is sequentially provided with a water-blocking layer 2 and an inner shielding layer outside the conductor 1 3. It is composed of insulating layer 4, outer shielding layer 5 and copper shielding layer 6. After several wire cores are cabled, a wire core water-blocking layer 7 is installed on the outside. The gap between the wire core water-blocking layers 7 is filled with filling strips 8. A wrapping tape 9 and an outer sheath 10 are arranged in sequence outside the core water-blocking layer 7 .

[0010] The invention solves the impact on the cable caused by the damage of the cable and the entry of water or water vapor during the joint, and reduces the resulting cost; moreover, the cable also plays a certain protective role after the cable is damaged after laying. At the same time, the cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com