Rotating table device of machine tool

A technology of rotary table and machine tool, used in manufacturing tools, metal processing equipment, metal processing machine parts, etc., can solve the problems of low work efficiency, decreased rigidity of rotary table, unusable clamping mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

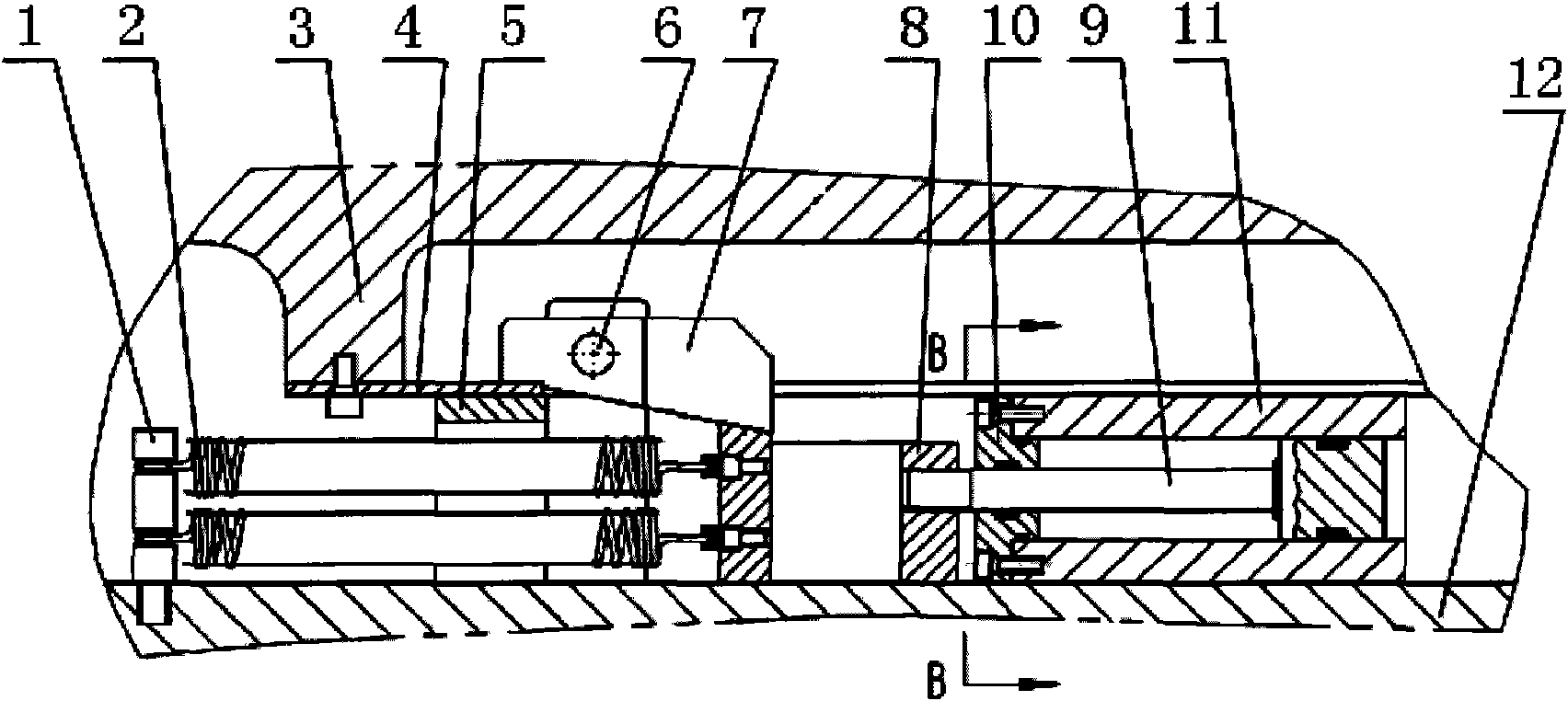

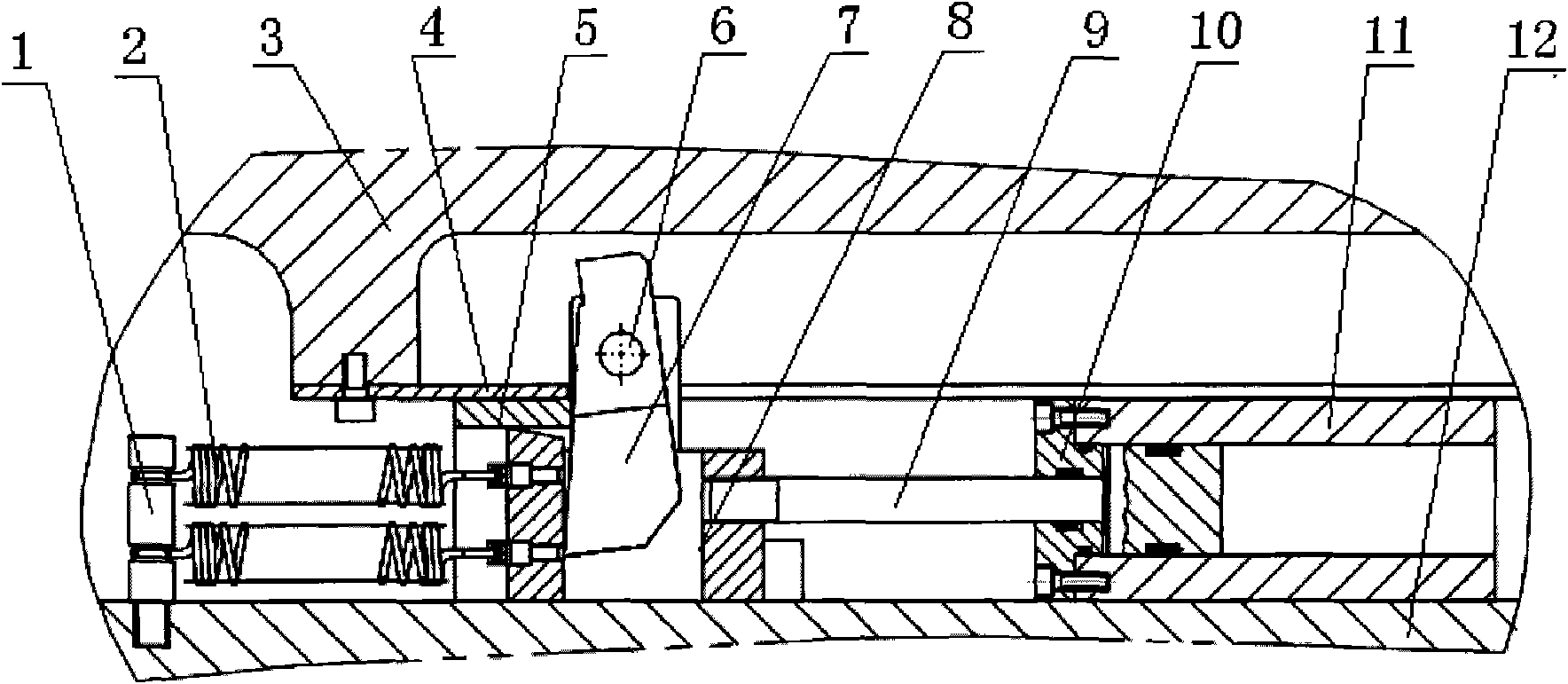

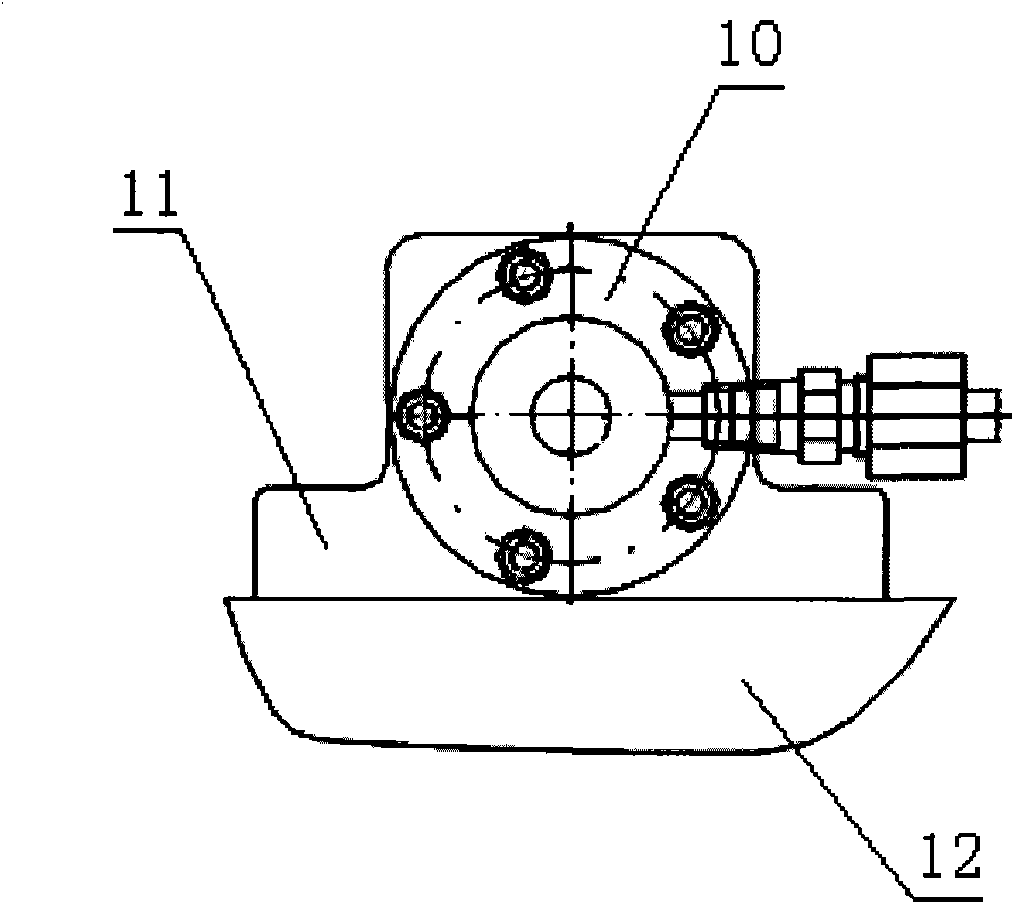

[0013] Such as figure 1 , figure 2 , image 3 As shown, a machine tool rotary table device includes a rotary table 3, a sliding seat 12 and a plurality of hydraulic clamping parts of the same structure evenly distributed around the rotary table 3, each hydraulic clamping part includes a rotary table 3 and the oil cylinder 11 between the sliding seat 12, the pin shaft 6 fixed on the side of the rotary table 3, the pin 1 fixed on the sliding seat 12, the annular pressing piece 4 fixed on the lower part of the rotary table 3, and the The fixed support 5 below the compression piece 4, the pressure plate 7 rotating around the pin shaft 6, the tension spring 2 and the wedge 8, one end of the tension spring 2 is connected to the pin 1, and the other end of the tension spring 2 is connected to the wedge 8 Connection, the wedge 8 is affixed to the end of the piston rod 9 of the oil cylinder, and the center of gravity of the pressure plate 7 is located on the side of the center line ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap