Concave-convex small sphere grinding wheel dresser

A grinding wheel dresser and forward sliding technology, which is applied in the direction of abrasive surface adjustment devices, metal processing equipment, manufacturing tools, etc., can solve the problems of no calibration reference and difficulty in guaranteeing the accuracy of processing dimensions, etc., and achieve stable installation, reasonable structure, and support stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

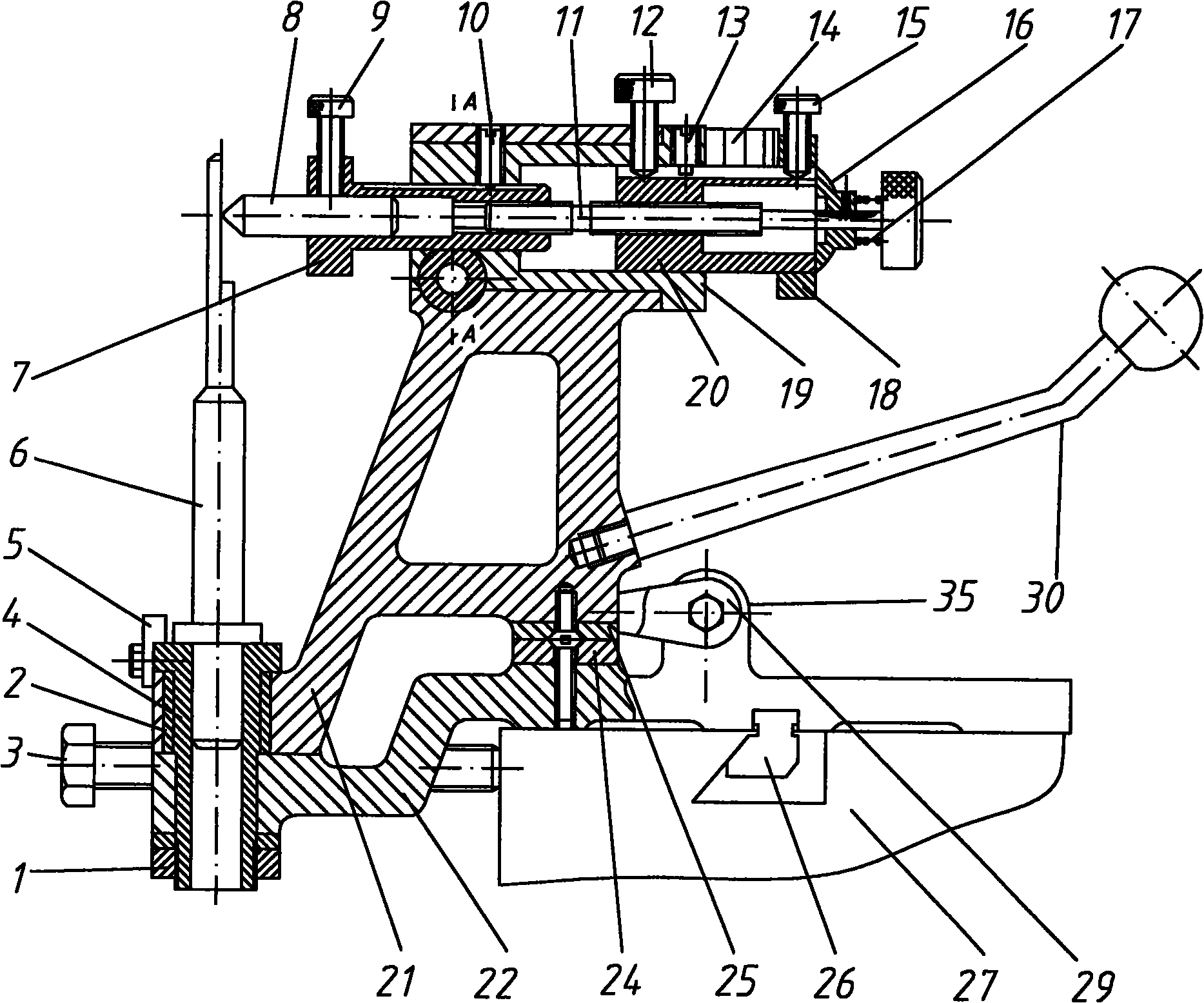

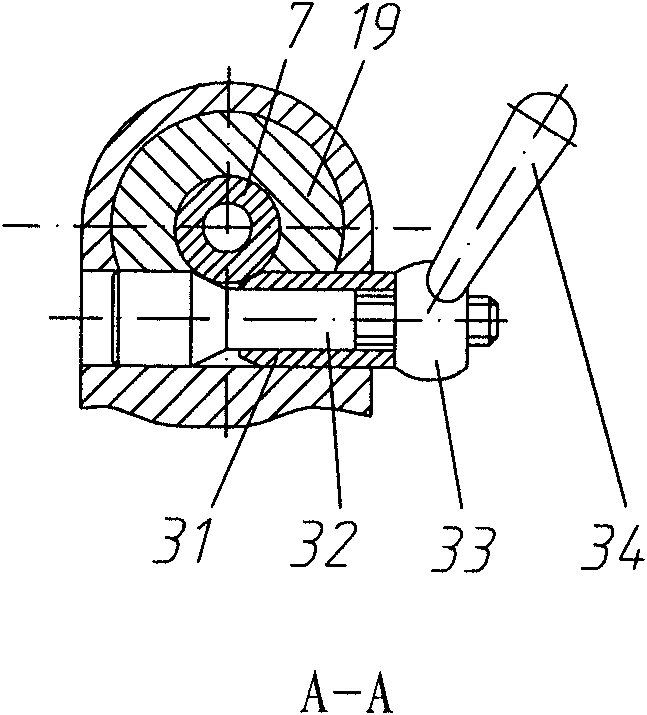

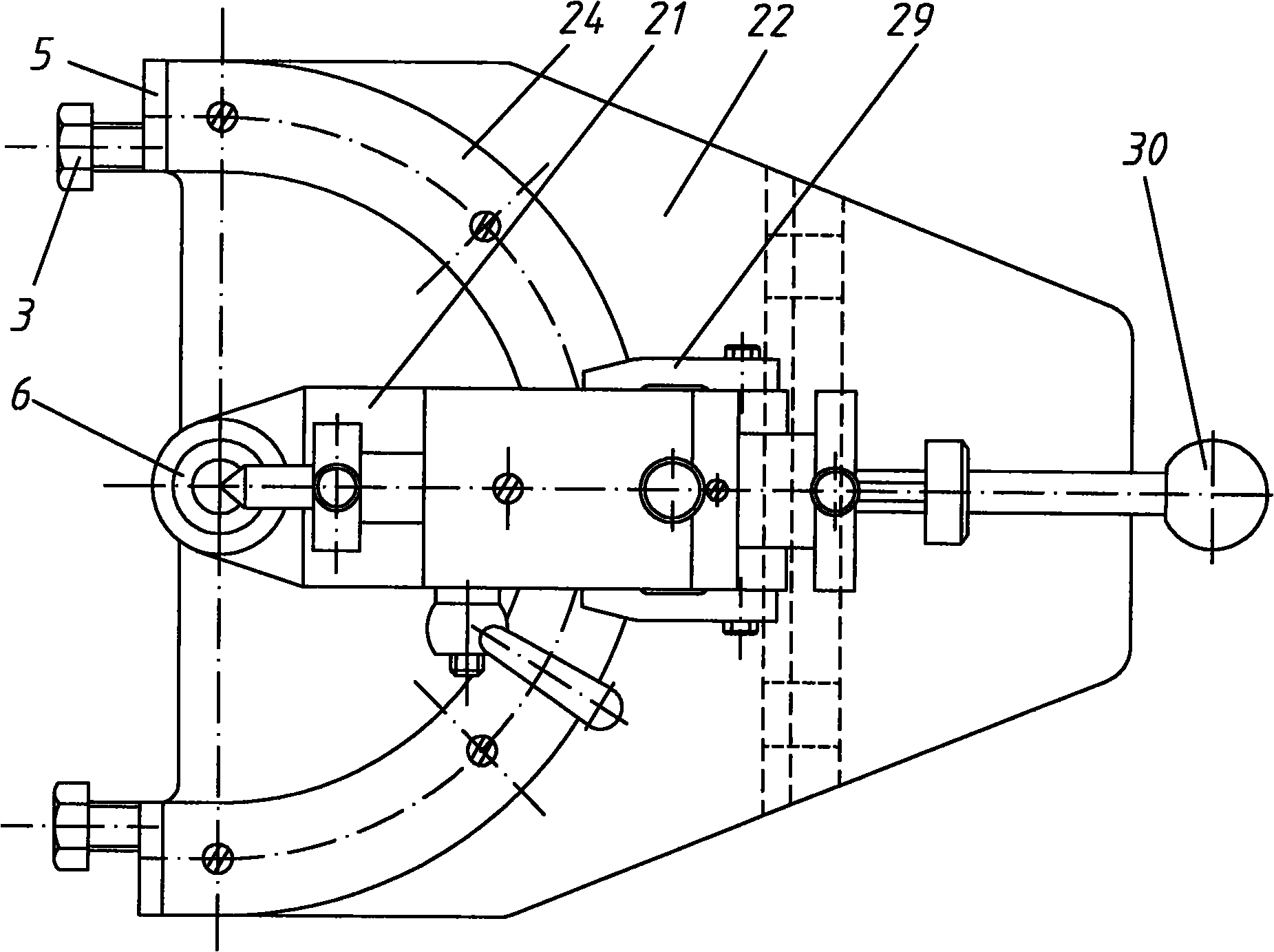

[0021] In specific implementation, such as Figure 1 to Figure 3As shown, a concavo-convex small spherical grinding wheel dresser includes a flat base 22 and a vertically arranged upper bracket 21, the base 22 is provided with a clamping device that can be fixed with the workbench 27 of the grinding machine, and the upper bracket 21 is provided with There is a diamond pen 8 and a feeding mechanism, a sleeve 4 is vertically arranged in the middle part of the left end of the base 22, and the lower part of the left end of the upper bracket 21 is rotatably socketed on the sleeve 4; its characteristic is that the sleeve 4 is inserted A standard rod 6 is connected, and the upper end of the standard rod 6 is semi-cylindrical and corresponds to the diamond pen 8; the feed mechanism includes a fixed sleeve 19, a front sliding sleeve 7, and a r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap