Structure of water jet blade

A technology of cutter heads and water jets, applied in the direction of explosion generating devices, abrasives, metal processing equipment, etc., can solve problems such as multi-processing waste, complexity of secondary processing procedures, uneven water pressure in water outlet holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

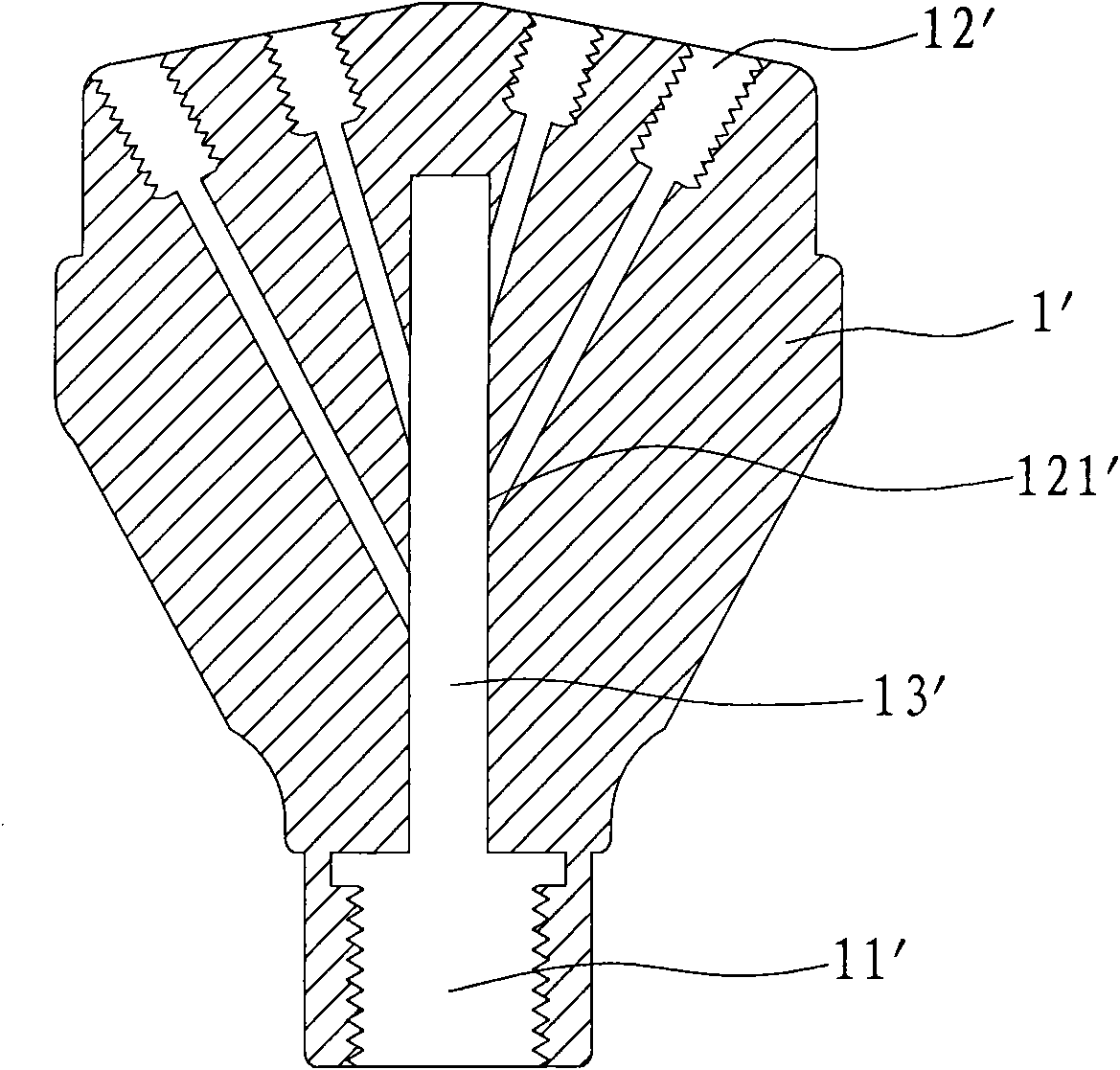

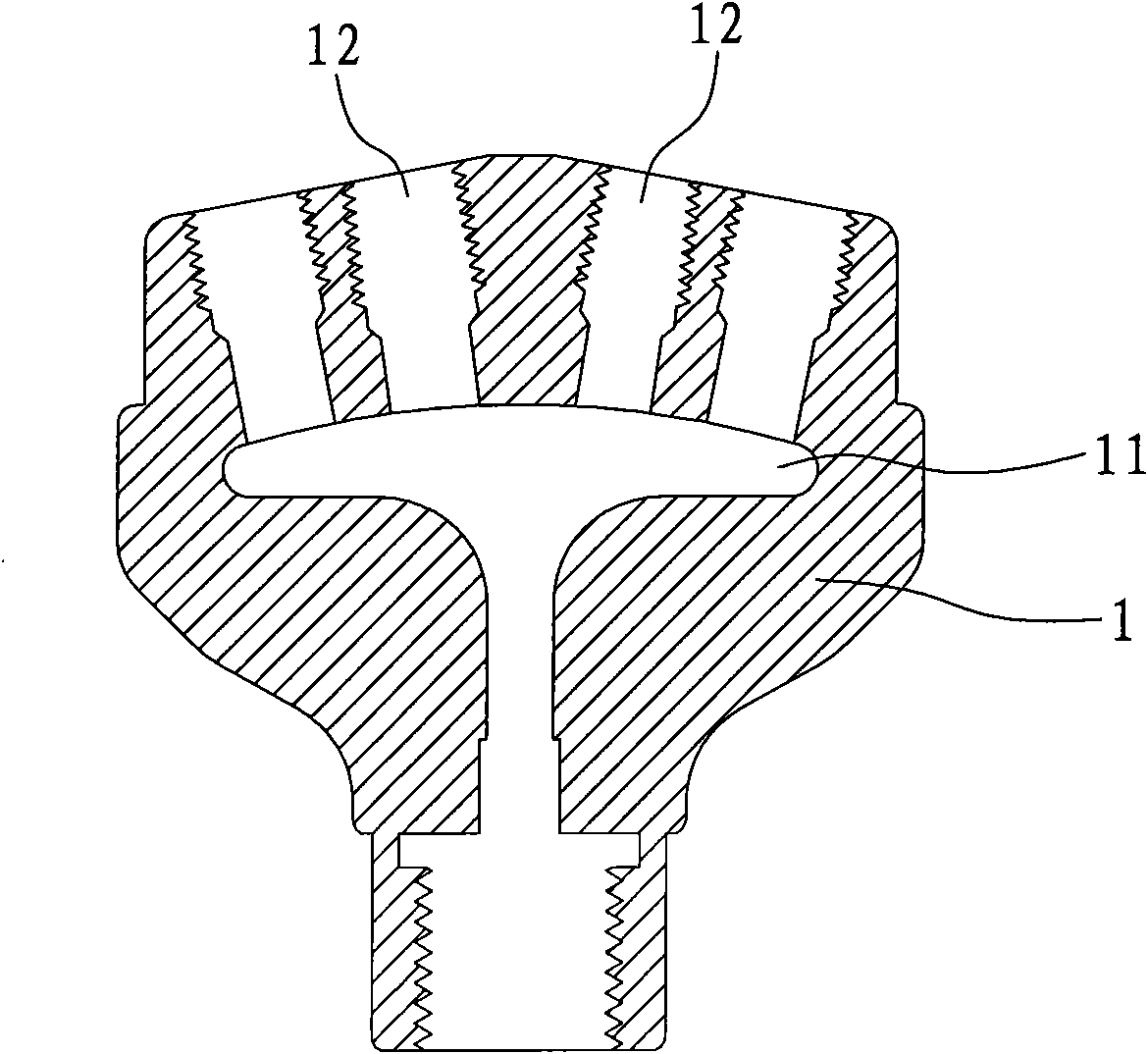

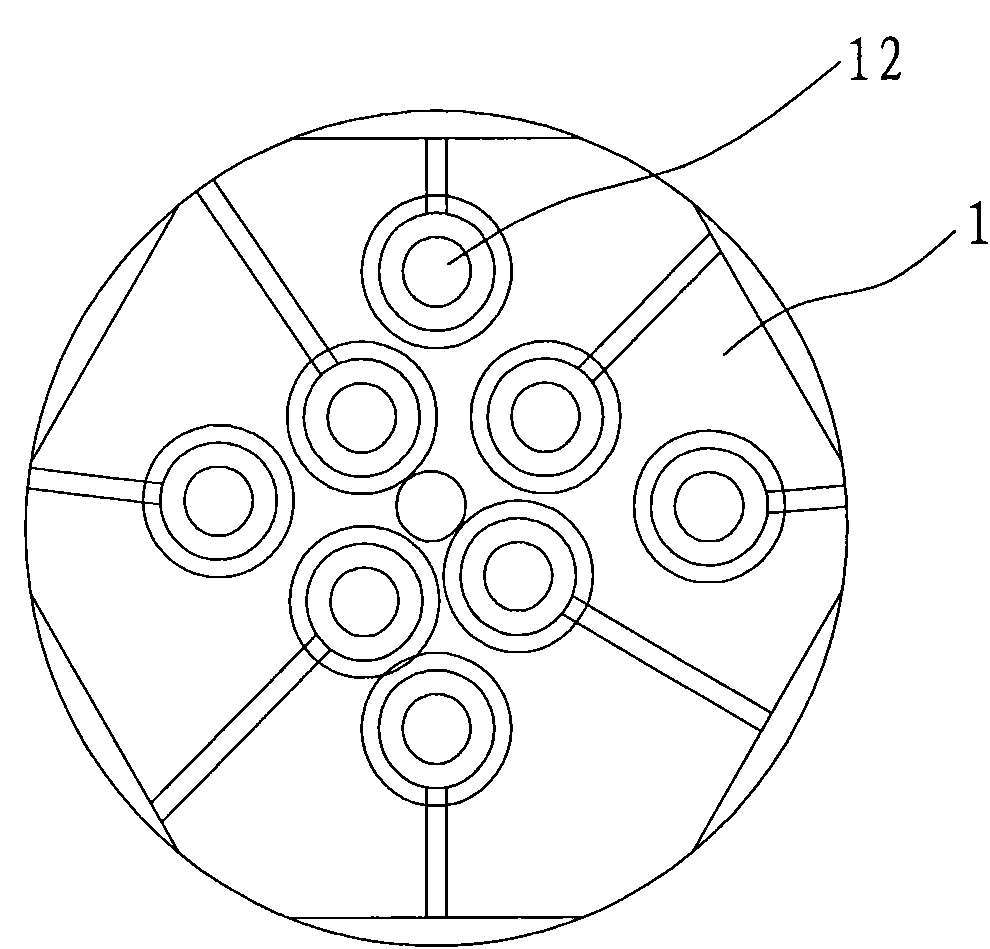

[0012] Such as figure 2 , 3 As shown, the present invention discloses a waterjet cutter head structure, the cutter head gradually expands from the rear to the front to form a tapered body 1, and at the same time, a tapered chamber 11 that gradually expands from the rear to the front is formed in the body 1 , the conical chamber 11 is formed in response to the shape of the conical body 1 to ensure uniform wall thickness between the body 1 and the chamber 11; a plurality of water outlet holes 12 communicating with the front end of the body 1 are formed at the bottom of the chamber 11 , The front end of each water outlet hole 12 is formed with a vertical guide portion to ensure that the water flow is sprayed downward.

[0013] The formation of the chamber 11 here is to ensure that the lengths of the water channels of the water outlet holes 12 are similar, and the pressure of the water flow ejected from the water outlet holes 12 is also similar, so that the water outlet pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com