Material packing machine with priming device

A technology of liquid injection device and packaging machine, which is applied in packaging, packaging food, packaging protection, etc., which can solve the problems of difficult carrier material mixing evenly, uneven effect of small package products, and unstable effect of materials, so as to avoid performance changes , reduce the exposure time, and facilitate the transformation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will further illustrate and describe the material packaging machine with the liquid injection device according to the present invention in conjunction with the embodiments.

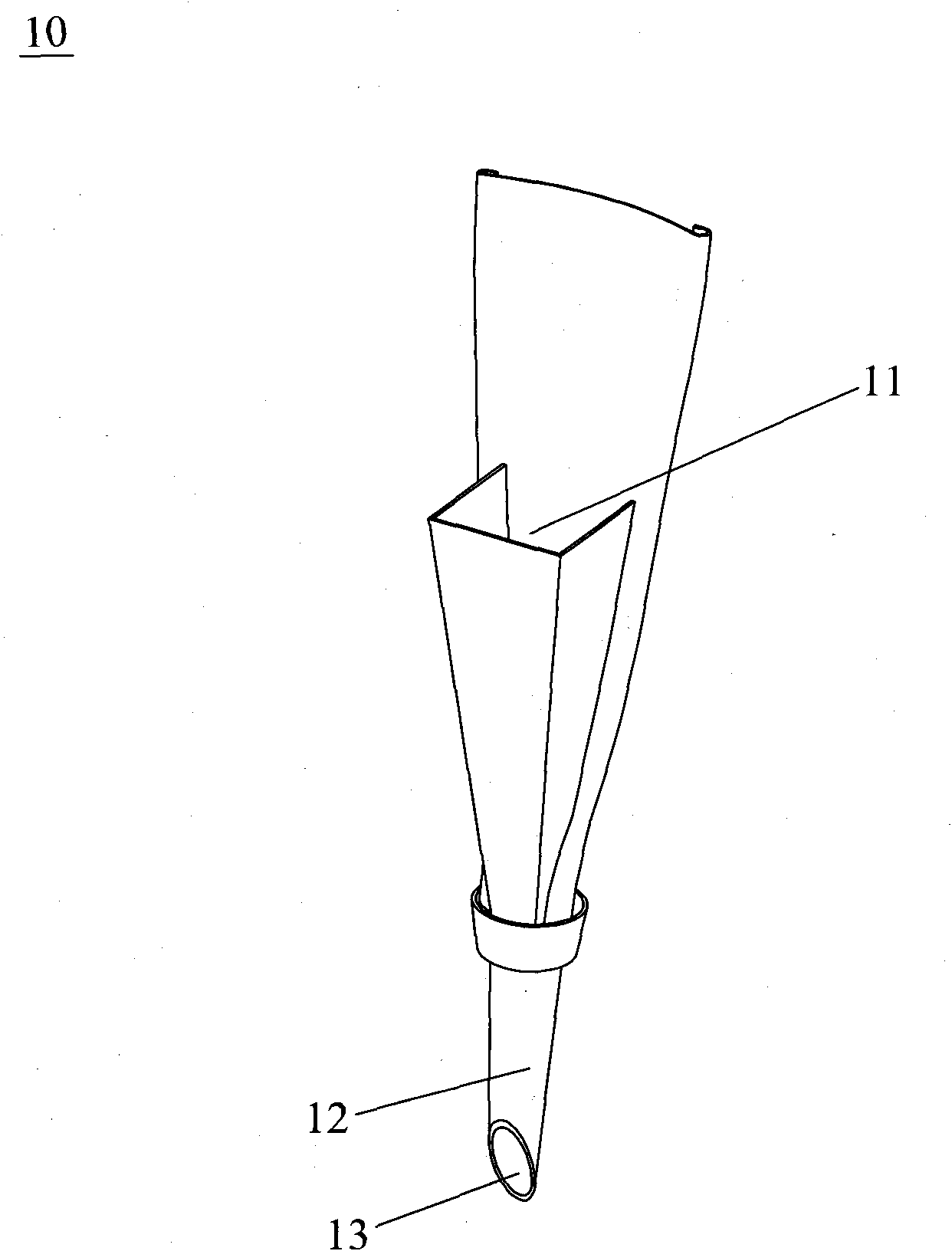

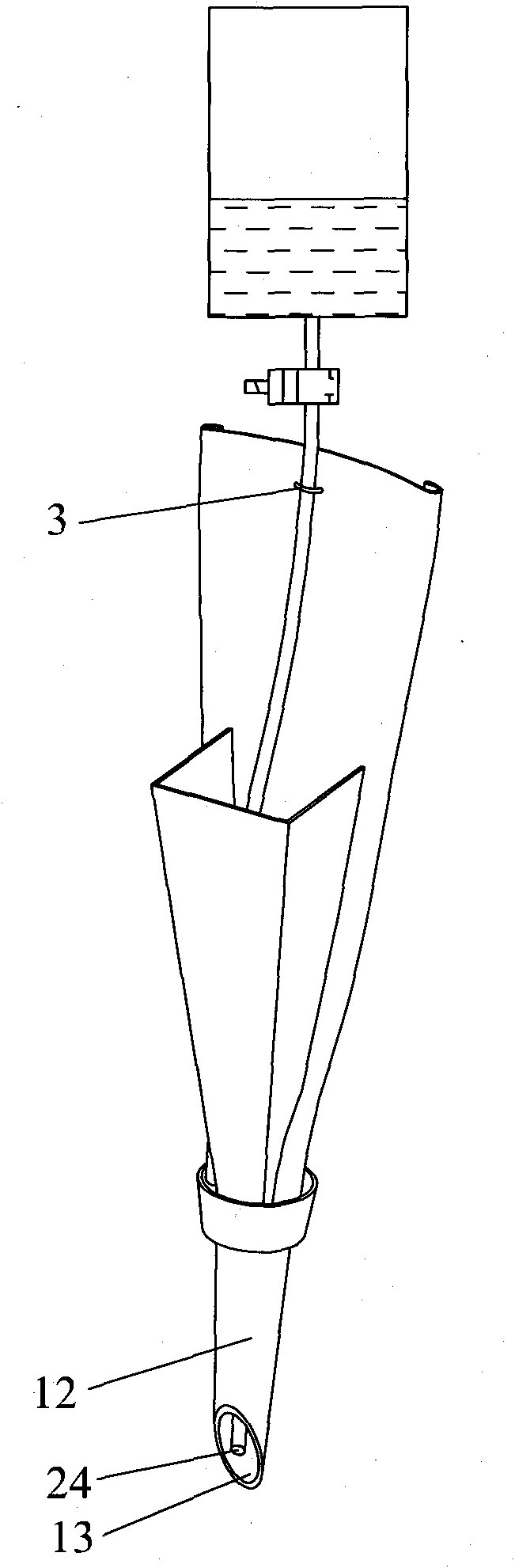

[0024] refer to figure 1 , a material packaging machine with a liquid injection device, has a feeding cavity 10 and a feeding nozzle 13. The feeding chamber 10 has a material tank 11 for containing materials, a feeding tube 12 located below the material tank 11 and communicating with the material tank, and a feeding nozzle 13 located at the end of the feeding tube 12 .

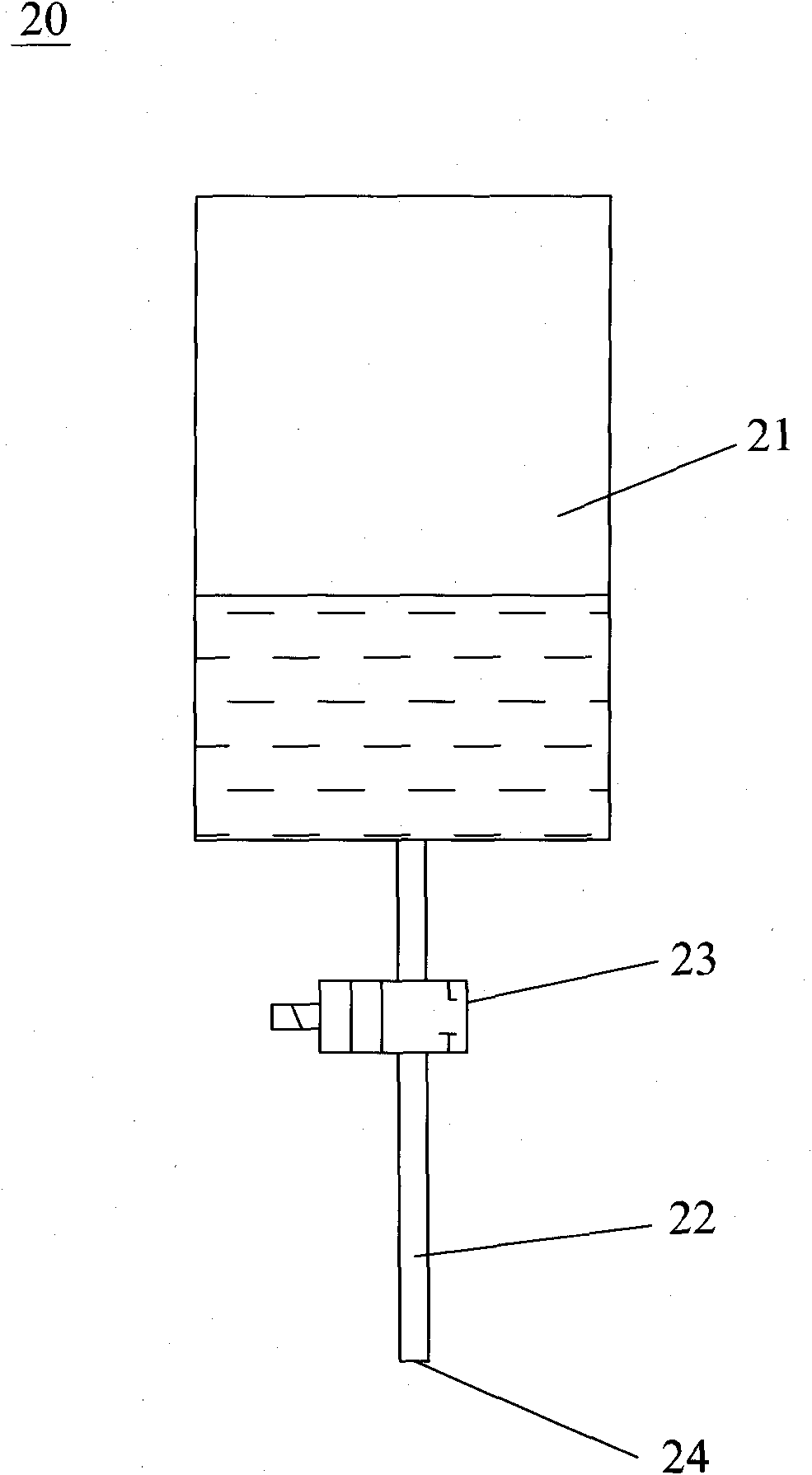

[0025] refer to figure 2 , figure 2 A liquid injection device 20 of a material packaging machine with a liquid injection device according to the present invention is shown. The liquid injection device 20 has a liquid storage tank 21 and a pipeline 22 communicating with the lower part of the liquid storage tank 21 . A solenoid valve 23 for controlling material flow is installed on the pipeline 22 , and a material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com