Additive ZF of recyclable waste anti-wear hydraulic oil HM68

A technology of anti-wear hydraulic oil and additives, which is applied in the direction of lubricating compositions, etc., can solve the problems of undiscovered, uneconomical practicability, high cost, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0007] Example 1: Combine glycerol trioleate 40g, 103 calcium petroleum sulfonate detergent (unified code is T103-see: China Petrochemical Products Encyclopedia P.431) 25g and 204 antioxidant and anticorrosive agent (unified code is T204- See: China Petrochemical Products Encyclopedia P.441) 35g, reacted at 125±2℃ to become additive ZF. According to the recycled waste anti-wear hydraulic oil HM68, the weight of the waste anti-wear hydraulic oil HM68 containing dewatering and residue is 98.5% , The weight of the additive ZF is mixed at a ratio of 1.5%, and the mixture is stirred at room temperature for 20 minutes to regenerate the waste anti-wear hydraulic oil HM68.

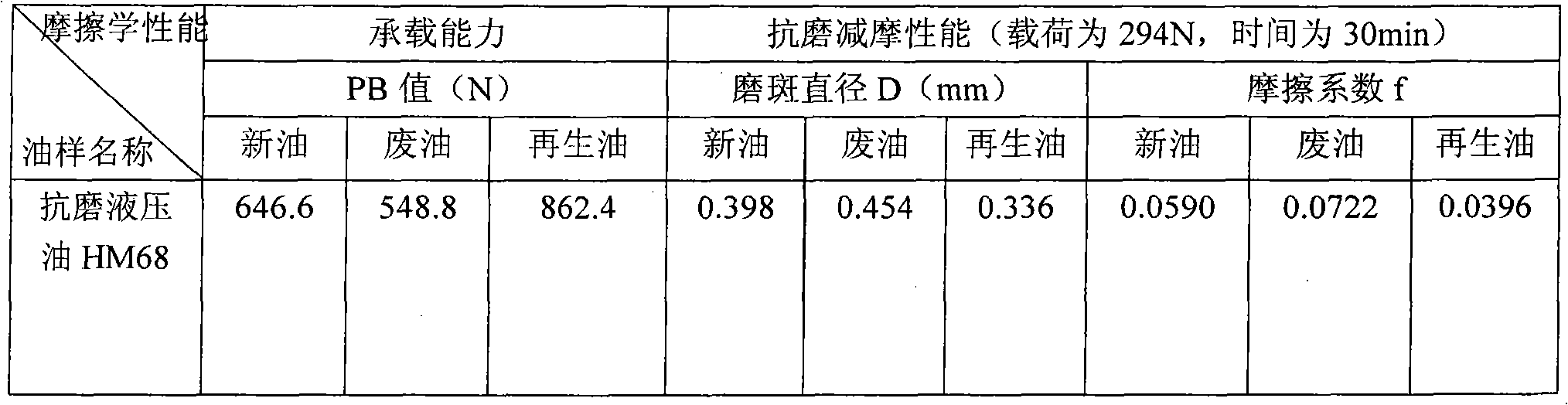

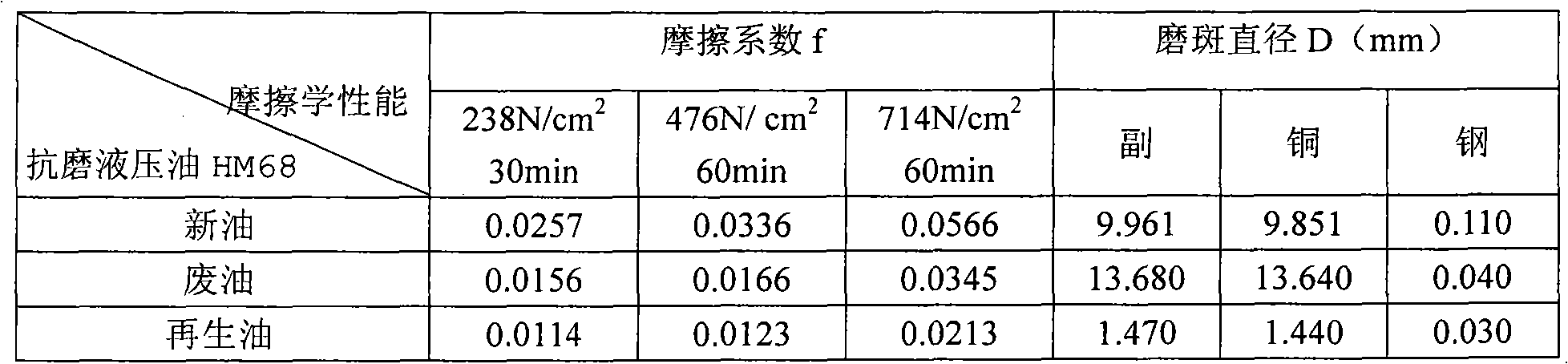

[0008] After regeneration, the tribological function is restored, and it is also significantly better than the original new oil: the friction coefficient of the steel / steel friction pair is reduced by 32.88% compared with the original new oil, the wear is reduced by 15.5% compared with the original new oil, and the be...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap