Automatic mast angle adjustment device for core-drilling machine

An automatic adjustment, core drilling rig technology, applied in the field of core drilling rigs, can solve problems such as stuck drilling, damage to machinery and equipment, affecting work progress, etc., to avoid manual adjustment of drilling angle work, easy installation and use, to avoid stuck drilling effect of accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

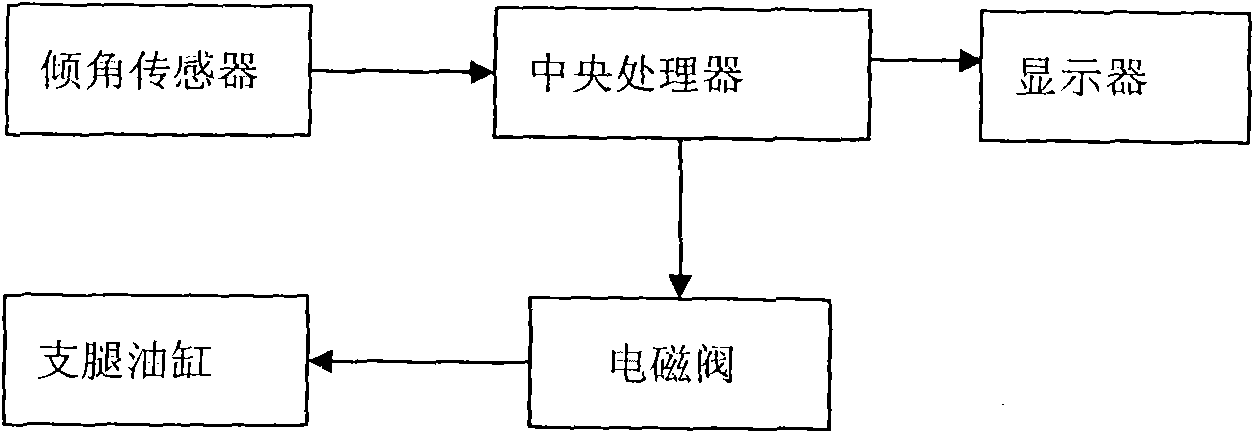

[0012] like figure 1 As shown, the mast angle automatic adjustment device for the core drilling rig has an inclination sensor, and the inclination sensor sends the collected drilling angle signal to the central processing unit, and the central processing unit analyzes and processes the drilling angle signal transmitted by the inclination sensor , the current angle information is displayed on the monitor, and the central processing unit is connected with the solenoid valve of the outrigger oil cylinder at the same time.

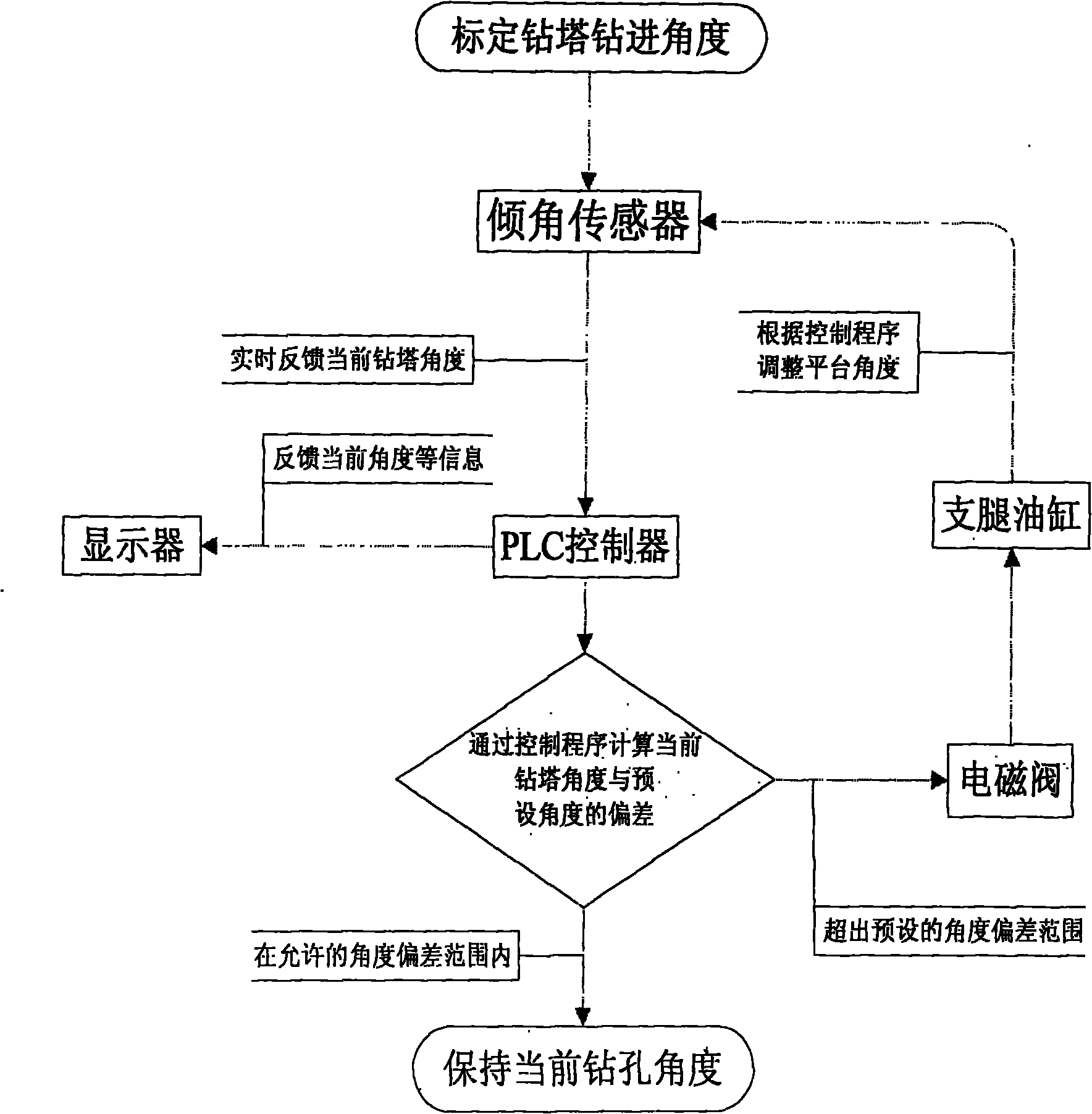

[0013] like figure 2 As shown, firstly, the drilling angle of the drilling tower is calibrated, and the inclination sensor collects the angle of the drilling tower in real time during drilling, and at the same time transmits the angle signal to the programmable controller; the programmable controller analyzes the signal sent by the inclination sensor, that is, through the The internal control program of the programmable controller calculates the deviation be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com