Device for testing flow characteristics of gas-gas nozzle

A technology of flow characteristics and test equipment, applied in jet propulsion equipment, rocket engine equipment, machines/engines, etc., can solve the problems of affecting the flow of orifices, manpower, material resources, time loss, and high cost, and achieve stable and accurate feedback. environment, the design method is simple and effective, and the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

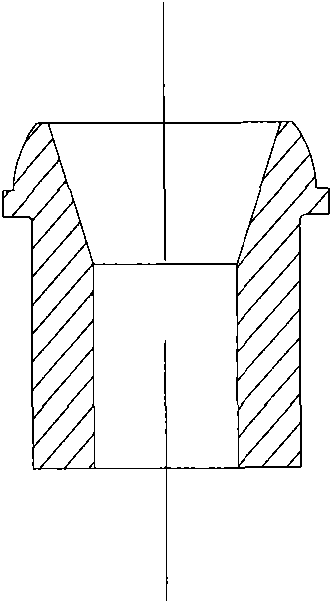

[0015] The invention proposes for the first time to use a throttling ball head with a throttling hole to throttle the gas propellant ejected from the gas-gas nozzle, so as to establish a back pressure environment for the flow characteristic test of the gas-gas nozzle. By replacing the throttling ball heads with different throttling apertures, any required pressure environment can be established for the gas-gas nozzle flow characteristic test, and the pressure environment is accurate and stable.

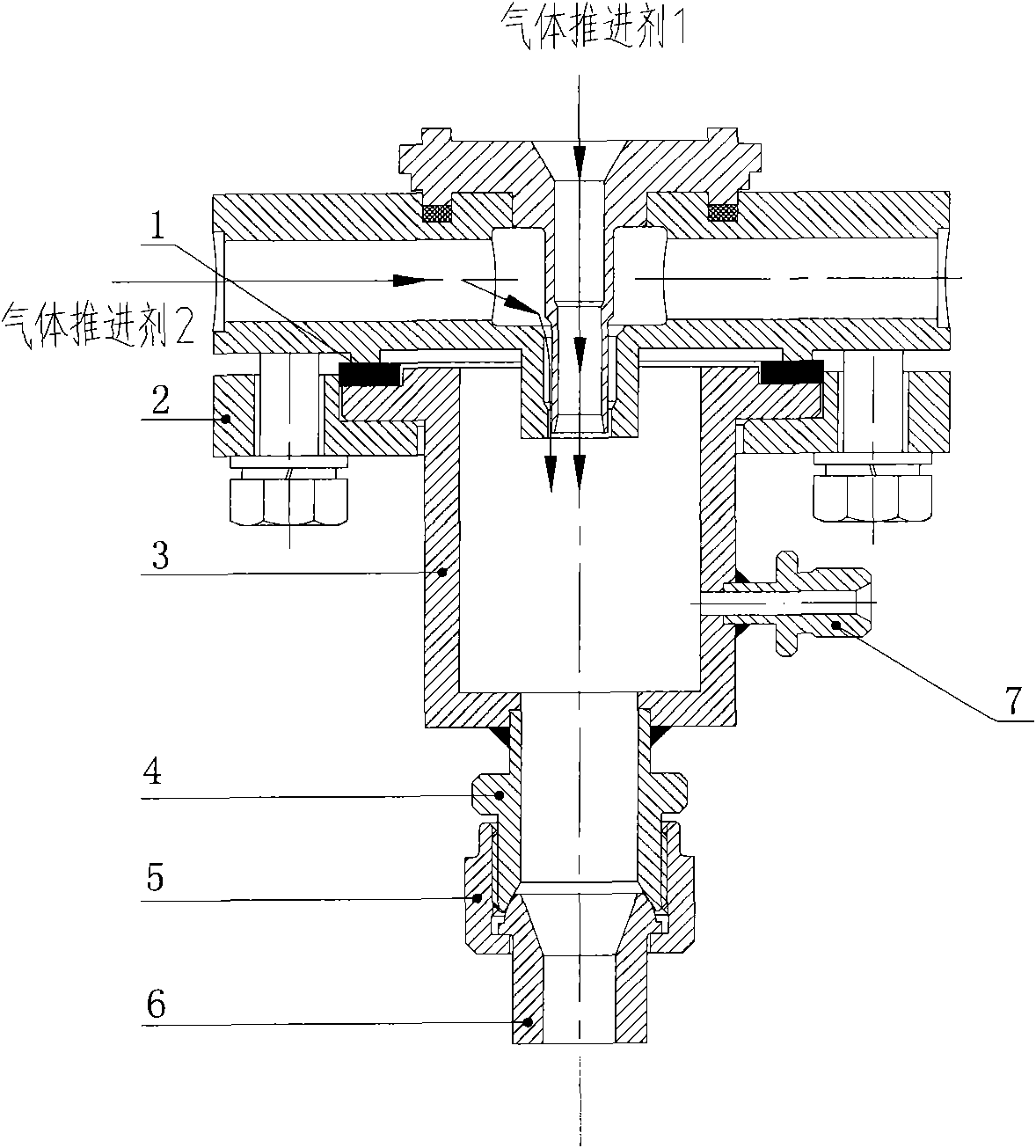

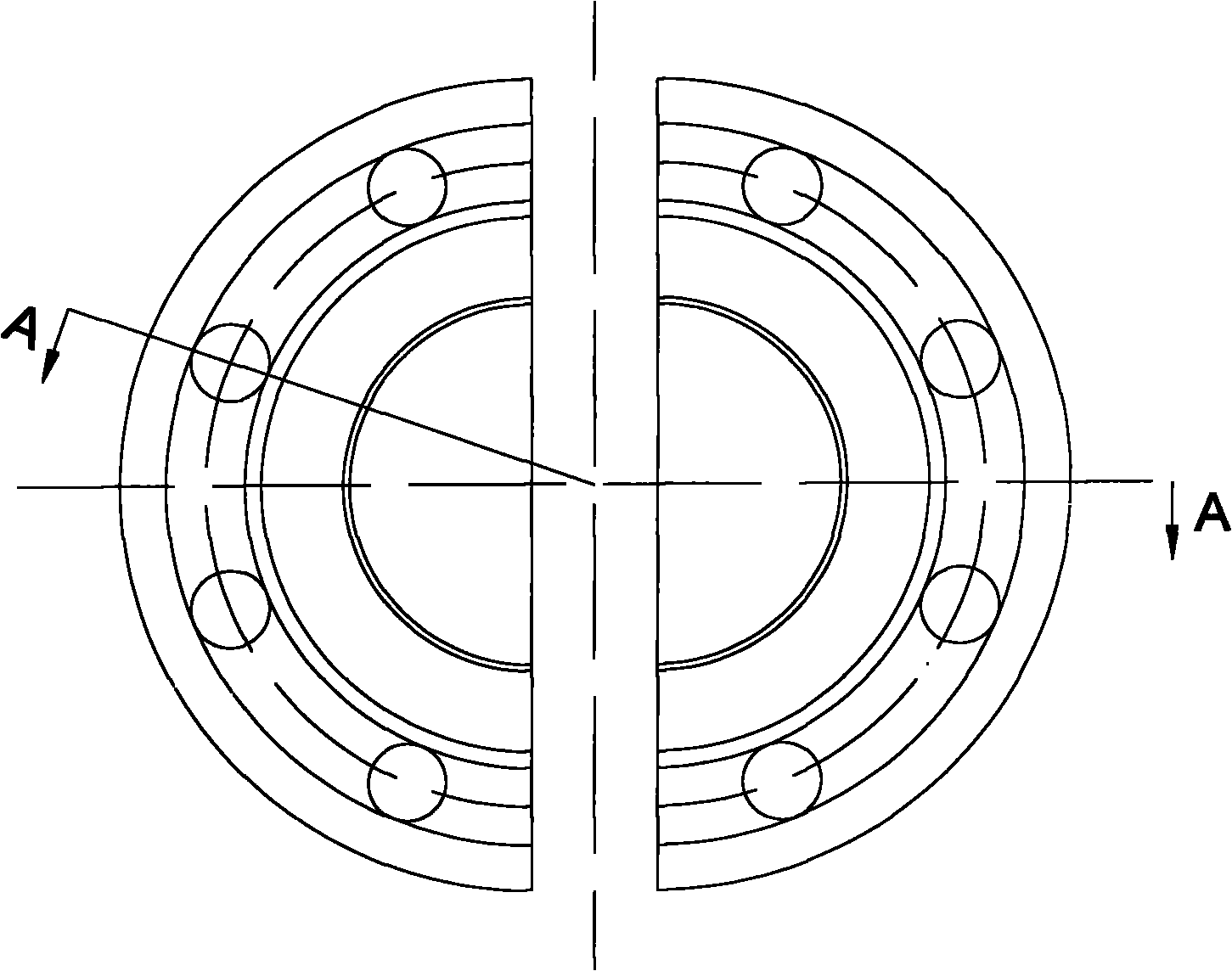

[0016] Such as figure 1 The air-air nozzle cold flow test device shown includes a gasket (1), a broken flange (2), a cavity (3), a nozzle (4) (7), an outer casing nut (5), a throttle ball head (6).

[0017] The design method of this test device is as follows:

[0018] 1. The propellant flow rate and propellant type through the gas-gas nozzle before the test are determined, defined as Its gas constant is known.

[0019] 2. The propellant is sprayed into the cavity through the air-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap