Loop structure of bidirectional microchannel heat exchanger

A technology of microchannel heat exchanger and loop structure, which is applied in evaporator/condenser, lighting and heating equipment, refrigeration components, etc., to achieve the effect of lengthening refrigerant flow, sufficient heat exchange, and improved heat exchange performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

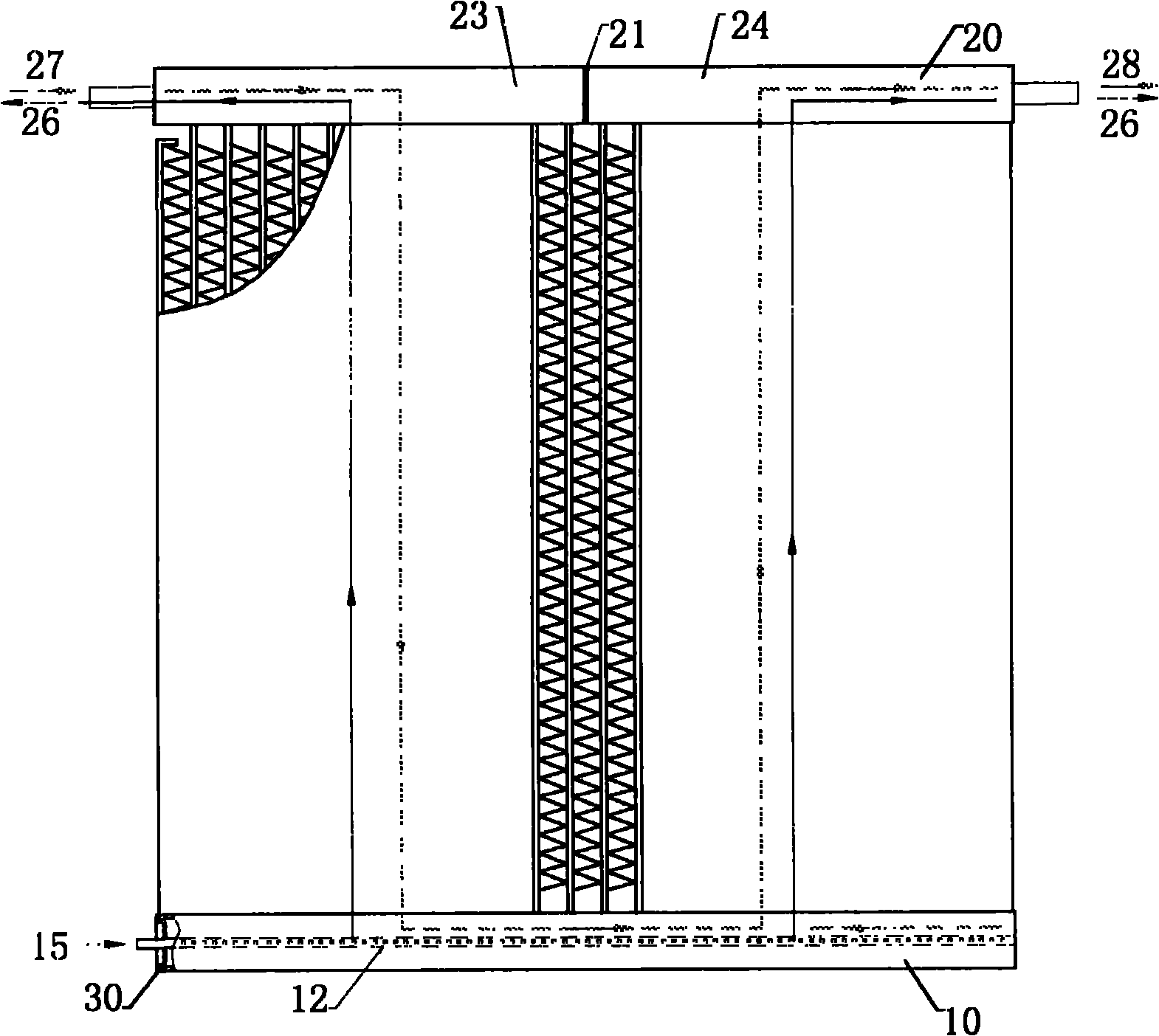

[0018] figure 1 is a schematic diagram of the loop structure of the bidirectional microchannel heat exchanger of the first embodiment.

[0019] Such as figure 1 As shown, the circuit structure of the bidirectional microchannel heat exchanger includes: a first header 10, a second header 20, a liquid separator 12, a separator 21, and a flat tube (not shown).

[0020] The first header 10 is provided with a plurality of flat tube slots, and the second header 20 is provided with flat tube slots corresponding to the number and positions of the flat tube slots on the first header 10, The parallel flat tubes are connected between the flat tube slots of the first header 10 and the flat tube slots of the second header 20 . The first collecting pipe 10 is provided with a liquid-distributing pipe 12, and a plurality of small holes are scattered on the liquid-distributing pipe 12. ) inner walls are welded together, and the other end runs through the left end cover 30 and extends to the ...

no. 2 approach

[0025] The basic structure of the circuit structure of the bidirectional microchannel heat exchanger of the second embodiment is the same as the basic structure of the circuit structure of the bidirectional microchannel heat exchanger of the first embodiment, and here, the same reference numerals are assigned to the same components.

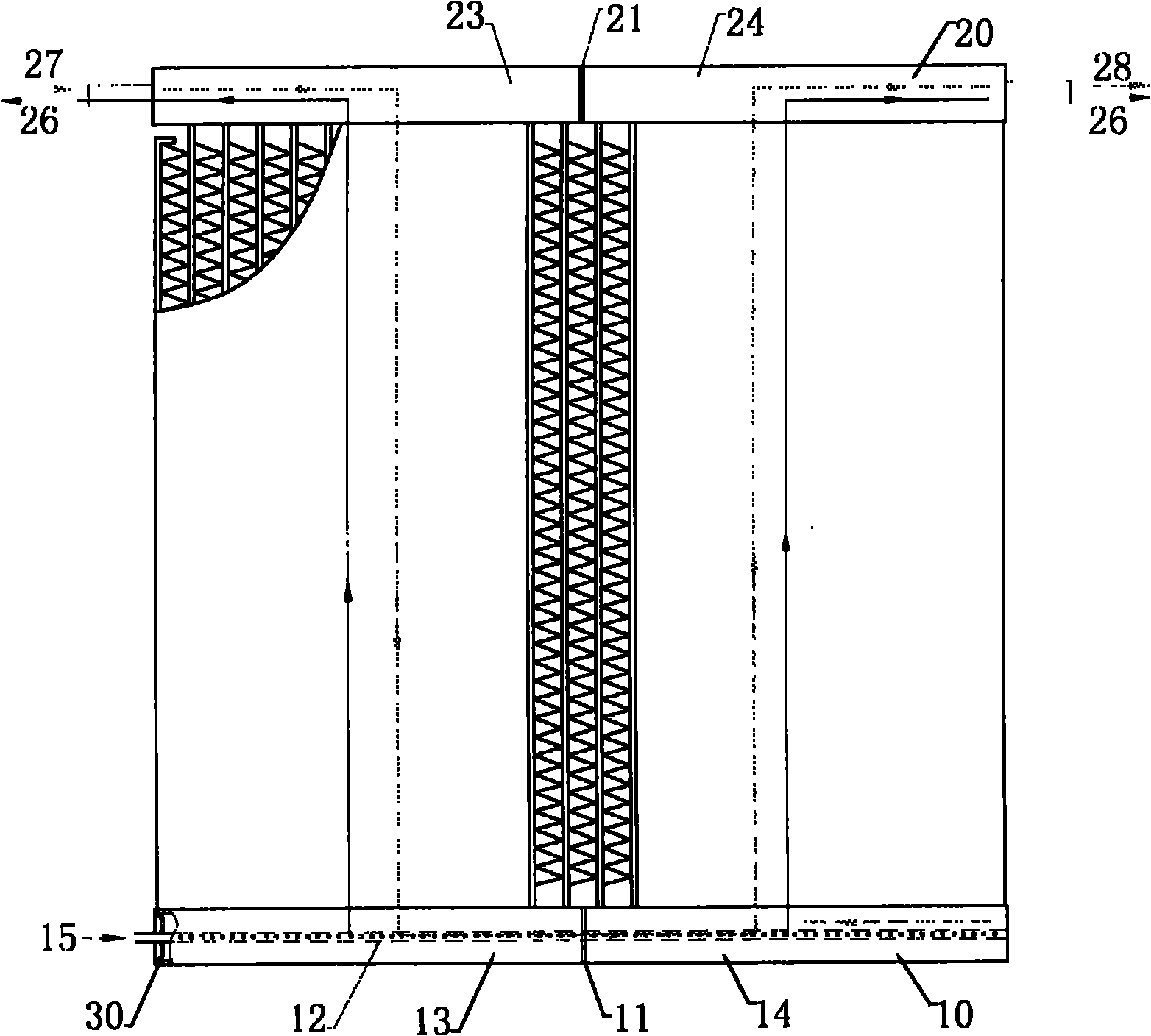

[0026] figure 2 It is a schematic diagram of the loop structure of the bidirectional microchannel heat exchanger of the second embodiment.

[0027] Such as figure 2 As shown, the circuit structure of the bidirectional microchannel heat exchanger includes: a first header 10, a second header 20, a liquid separator 12, a first partition 11, a second partition 21, flat tubes (figure omitted Show).

[0028] The first header 10 is provided with a plurality of flat tube slots, and the second header 20 is provided with flat tube slots corresponding to the number and positions of the flat tube slots on the first header 10, The parallel flat tubes are...

no. 3 approach

[0033] The basic structure of the circuit structure of the bidirectional microchannel heat exchanger of the third embodiment is the same as the basic structure of the circuit structure of the bidirectional microchannel heat exchanger of the first embodiment, and here, the same reference numerals are assigned to the same components.

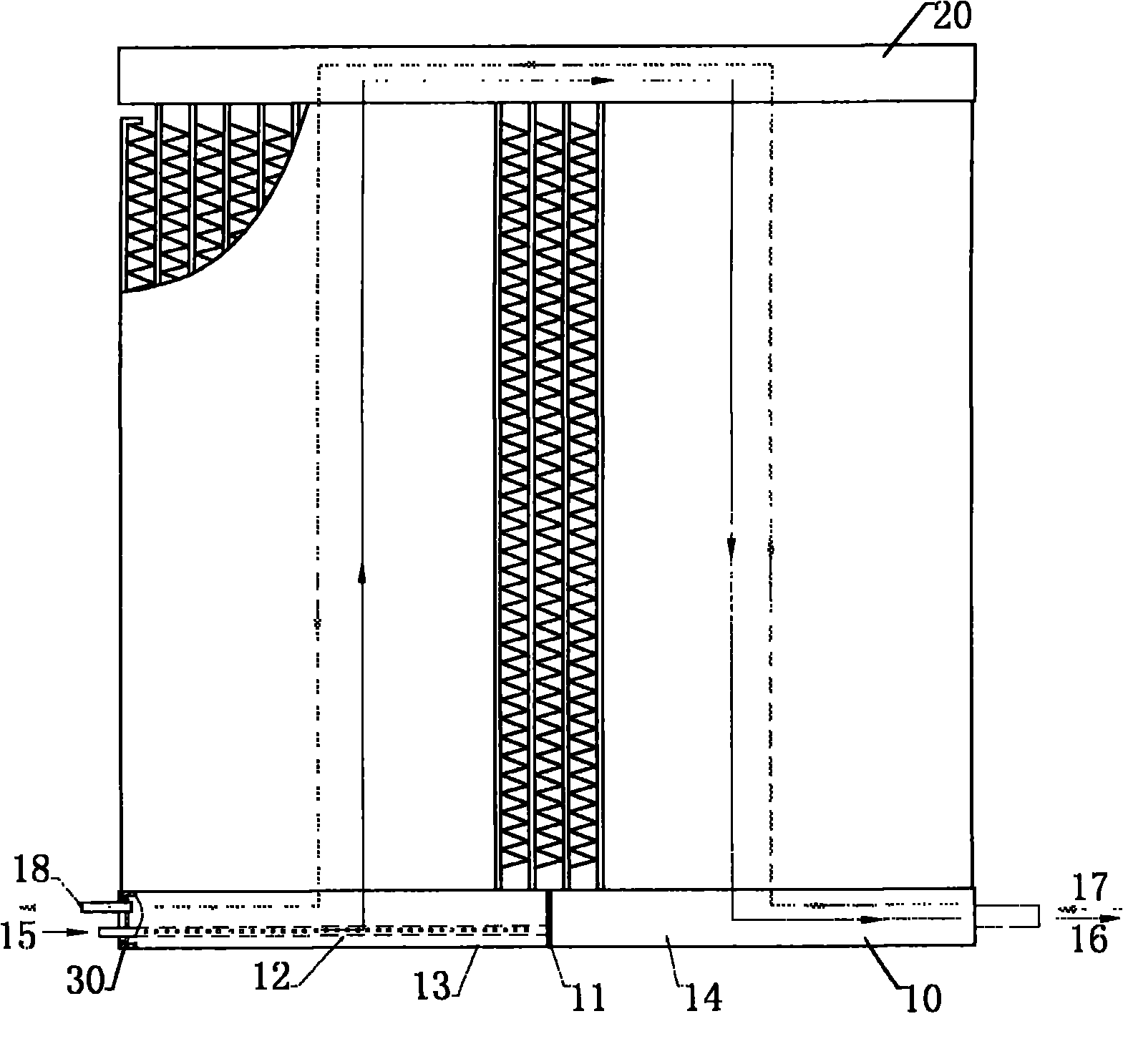

[0034] image 3 It is a schematic diagram of the circuit structure of the bidirectional microchannel heat exchanger of the third embodiment.

[0035] Such as image 3 As shown, the circuit structure of the bidirectional microchannel heat exchanger includes: a first header 10, a second header 20, a liquid separator 12, a separator 11, and a flat tube (not shown).

[0036] The first header 10 is provided with a plurality of flat tube slots, and the second header 20 is provided with flat tube slots corresponding to the number and positions of the flat tube slots on the first header 10, The parallel flat tubes are connected between the flat tube slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com