On-line water detection and pellet-fodder optimization device

A pellet feed and optimization device technology, applied in the direction of measuring devices, feed, analysis materials, etc., can solve the problems of unqualified moisture content indicators of finished materials, untimely moisture control, low work efficiency, etc., to achieve consistency and timely control , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

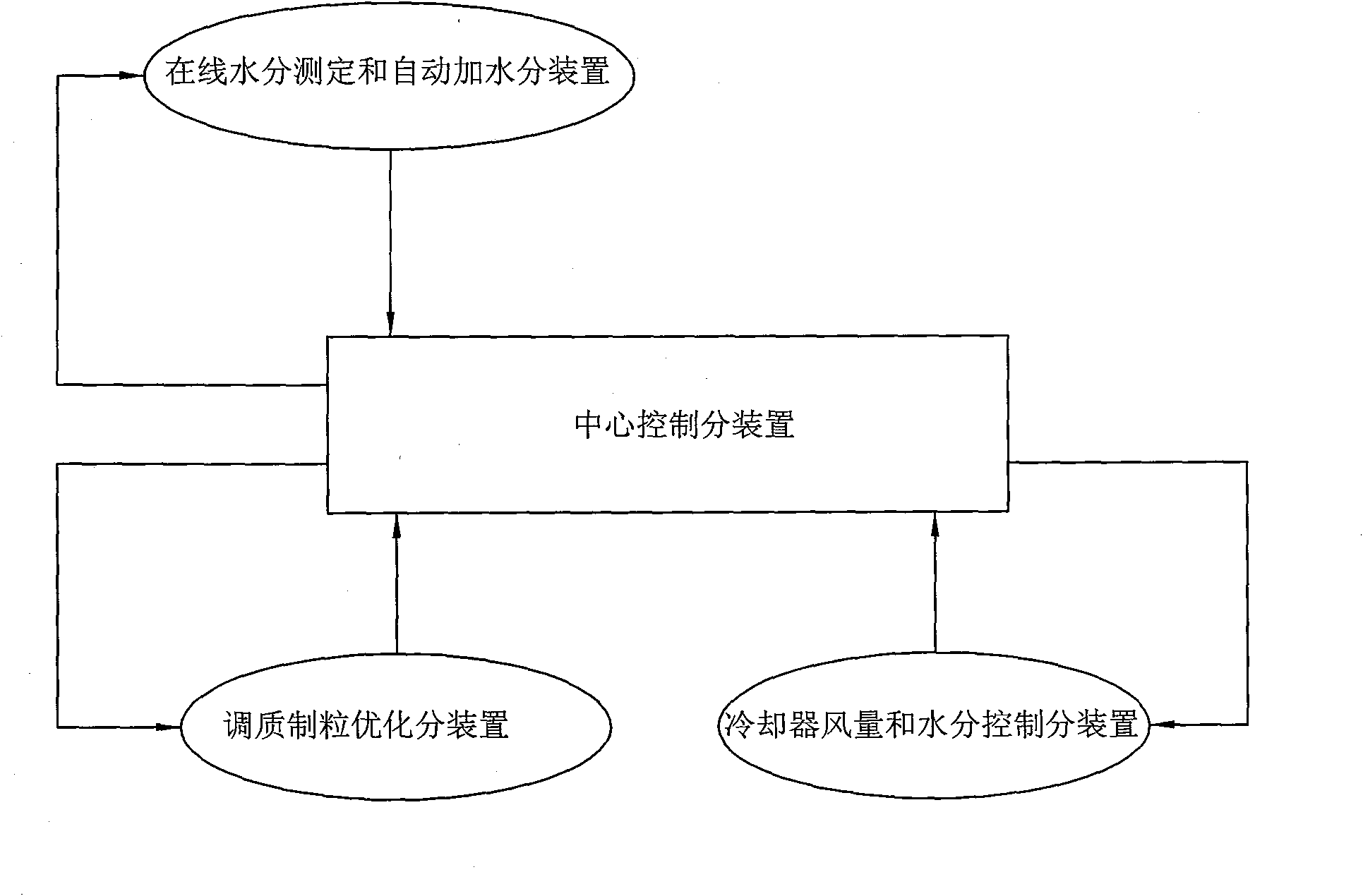

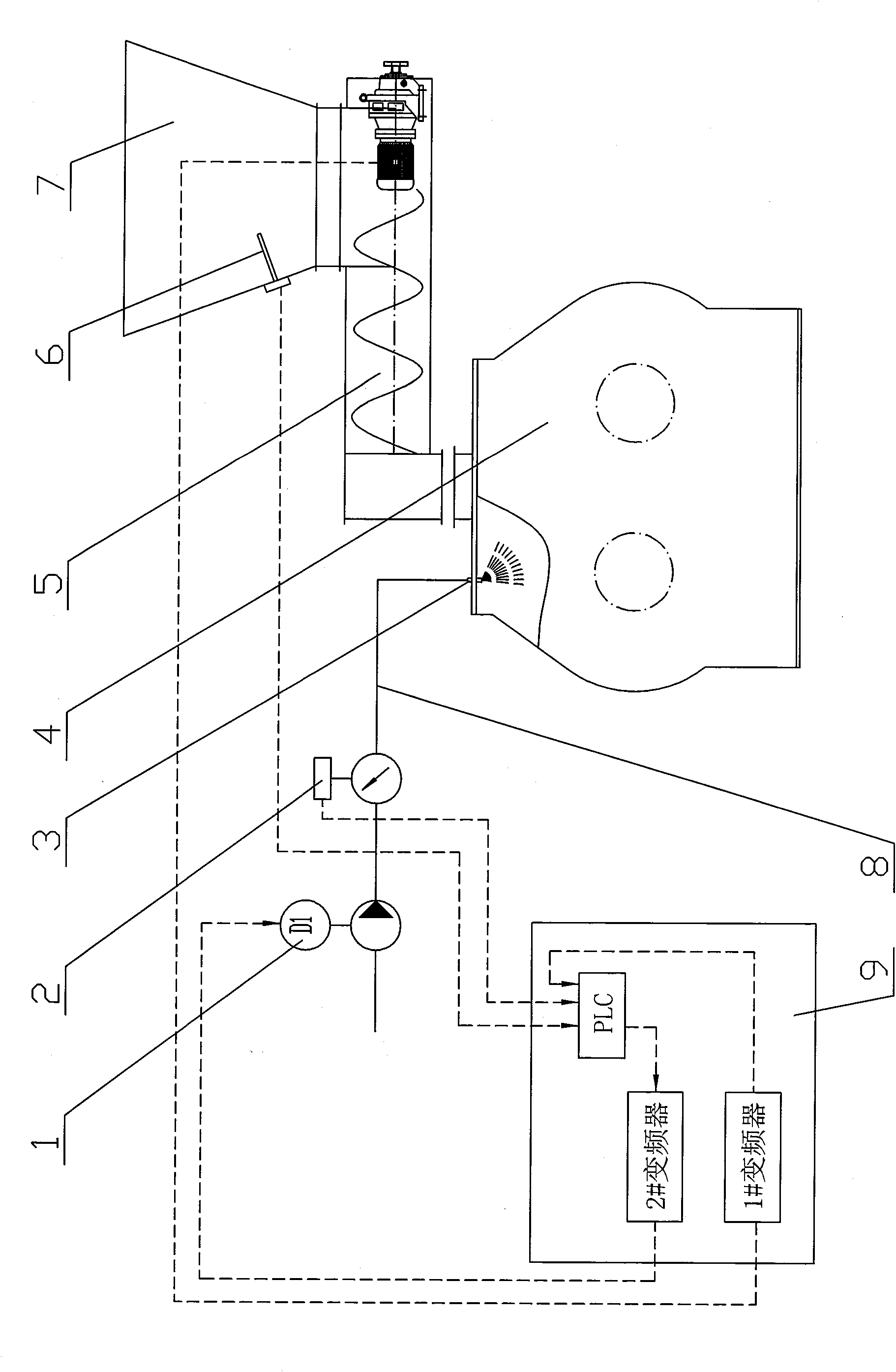

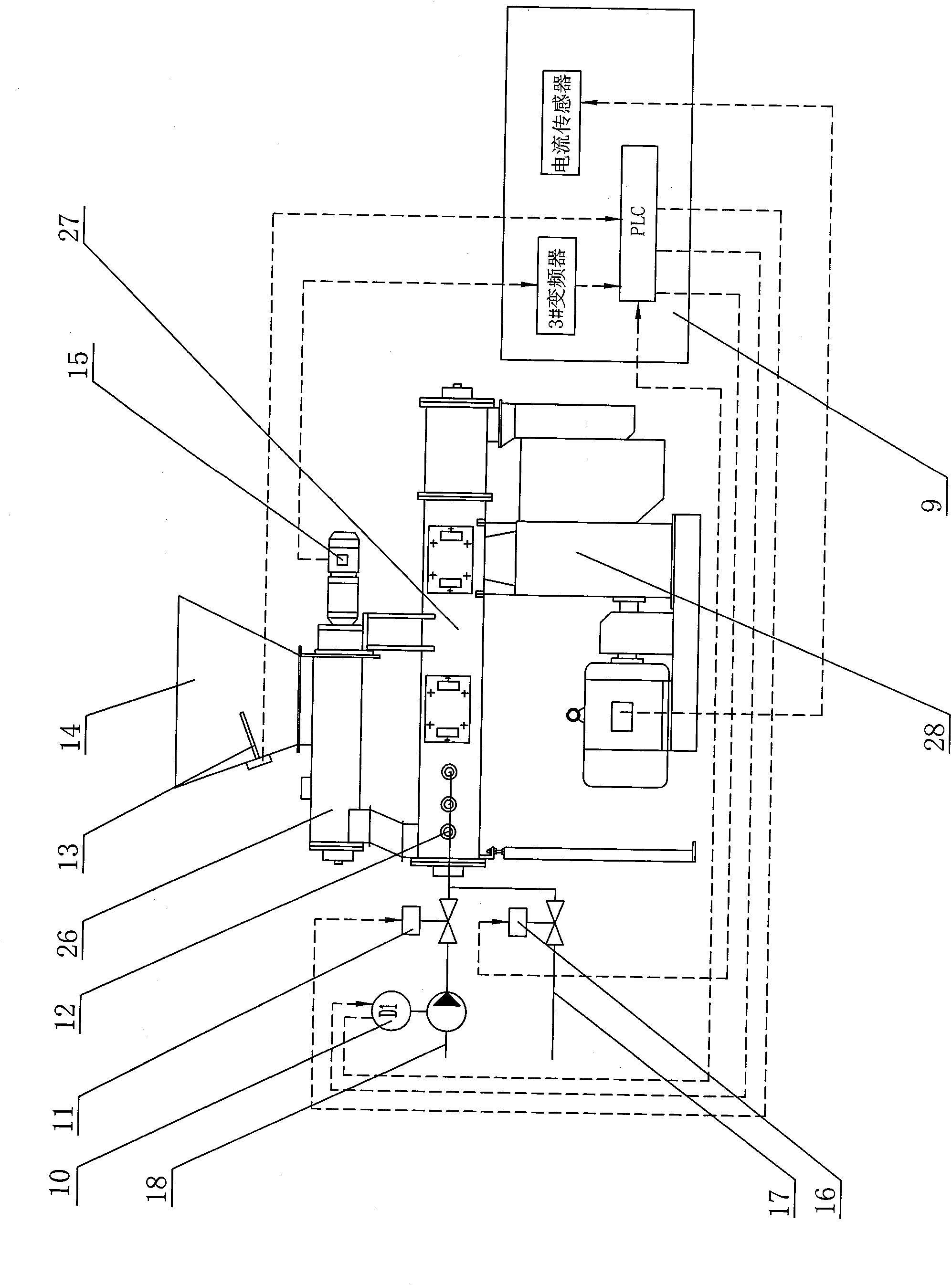

[0026] exist figure 1 Among them, the on-line moisture measurement and automatic water addition device, the tempering and granulation optimization sub-device, the cooler air volume and moisture control sub-device, and the central control sub-device constitute the online moisture detection and pellet feed optimization device.

[0027] The central control sub-device receives the online moisture measurement and the water flow in the automatic water adding device, the real-time moisture of the powder, the speed or output of the powder delivery; the water flow in the sub-device, the real-time moisture of the material, the material The speed or output of the conveying; the air volume of the cooler and the moisture control sub-device detect the moisture content of the finished material, the temperature of the finished material, and the level of the finished ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com