Electric precipitator

An electrostatic precipitator and electrostatic field technology, which is applied in the field of devices for separating dispersed particles, can solve the problems of affecting the dust removal effect of the electrostatic precipitator, excessive gas emission during cleaning, and dusting phenomena, etc., so as to achieve real-time and timely, eliminate The effect of secondary pollution and spatial volume dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

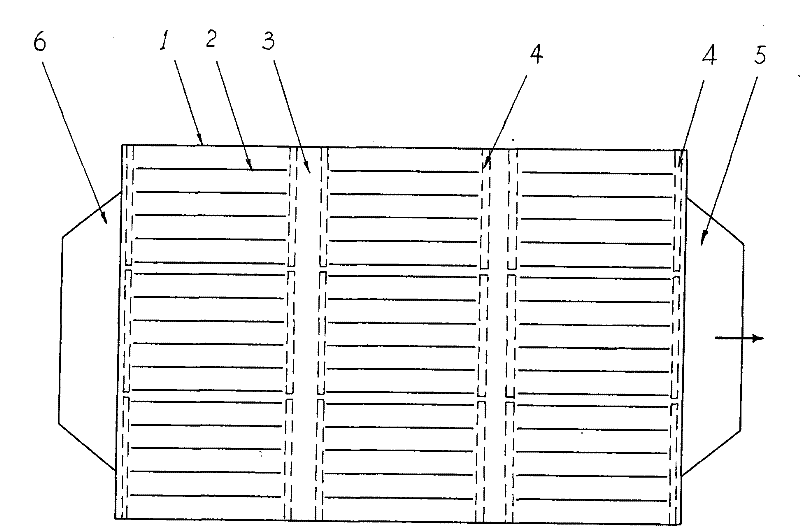

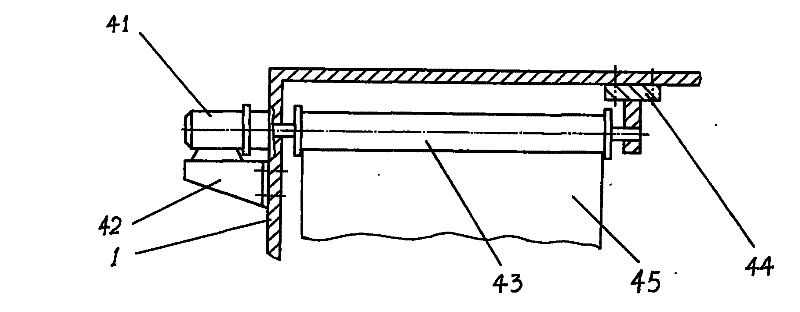

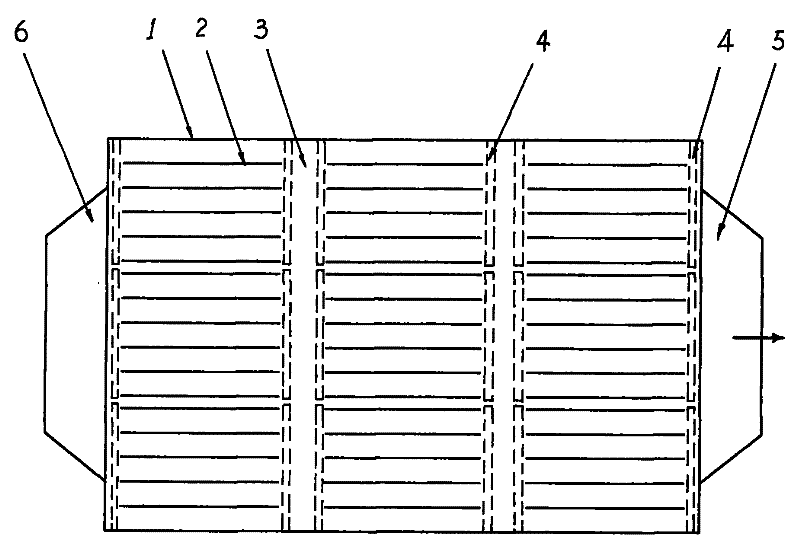

[0015] Such as figure 1 As shown, in the casing 1 of the electrostatic precipitator, there are three electrostatic fields arranged in sequence from the inlet 6 to the outlet 5. Each electrostatic field is composed of a number of dust removal electrode plates 2 arranged in parallel. Between two adjacent electrostatic fields There are corridors 3 vacated at intervals, and three electric roller shutter mechanisms 4 corresponding to each other are respectively installed on both sides of the top of the three electrostatic fields. That is to say, there are three electric roller shutter mechanisms 4 on each side of the electrostatic field, and the three electric roller shutter mechanisms 4 are adjacent to each other and arranged in a row. boards are connected. Thus, all the dust-removing electrode plates 2 in each electrostatic field are divided into three areas that can be sealed and isolated. According to the size of the electrostatic precipitator, each electrostatic field can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com