Metal bar material conveying device and application method thereof

A technology of conveying device and metal bar, which is applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problem of high labor intensity of operators, and achieve the effect of eliminating labor links.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The detailed structure of a metal bar conveying device and application method of the present invention will be described in conjunction with embodiments.

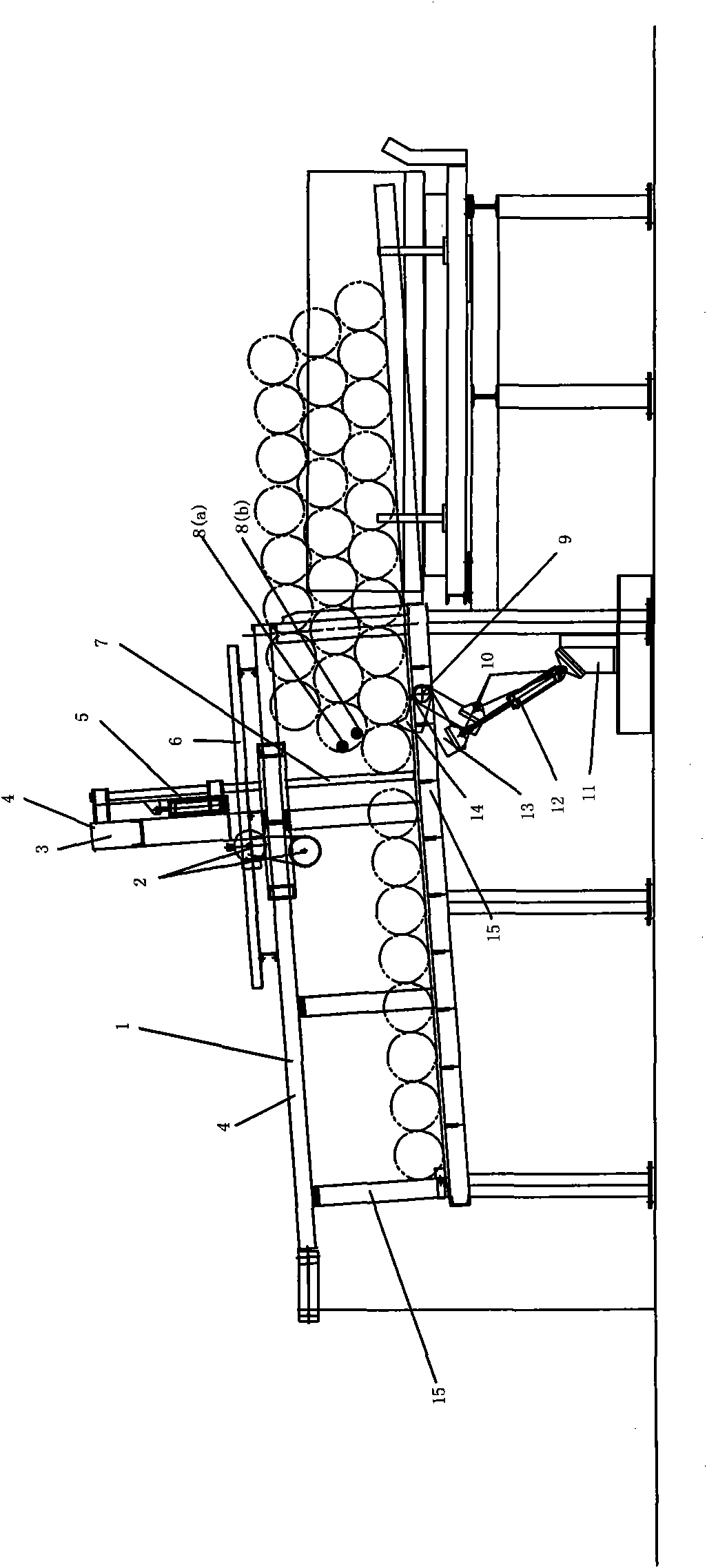

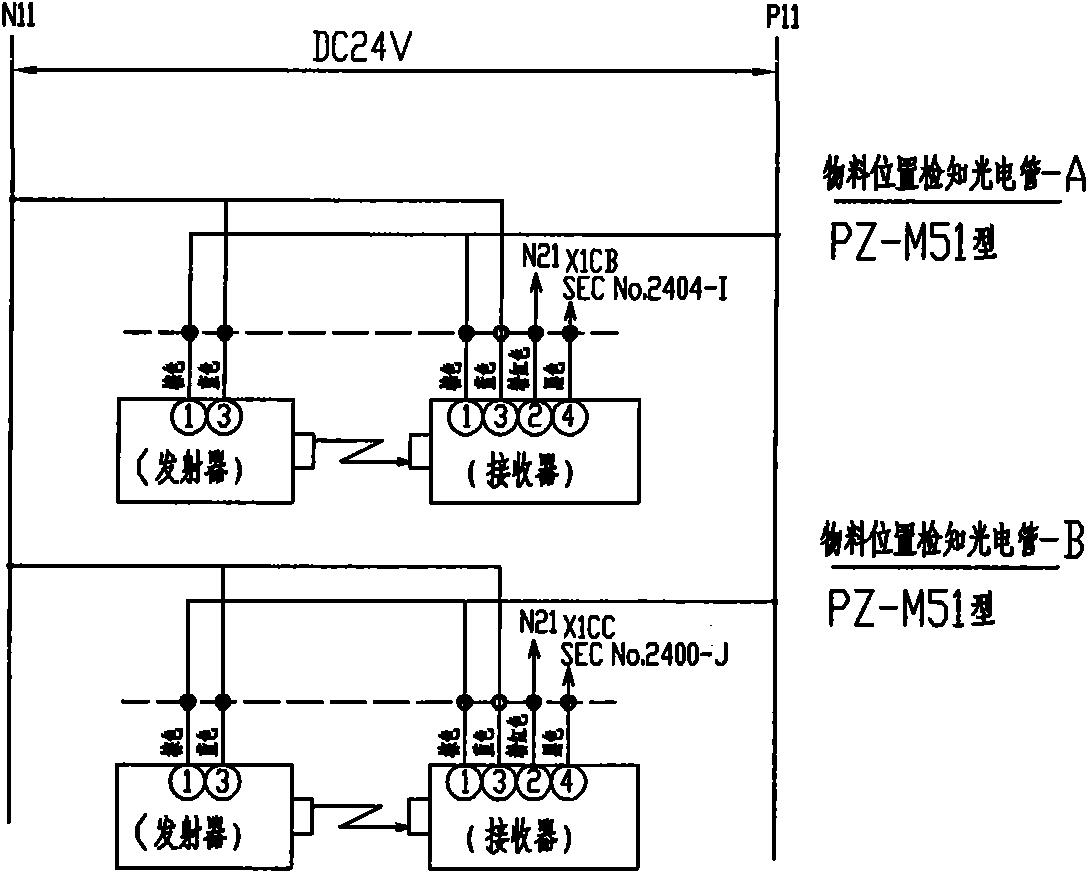

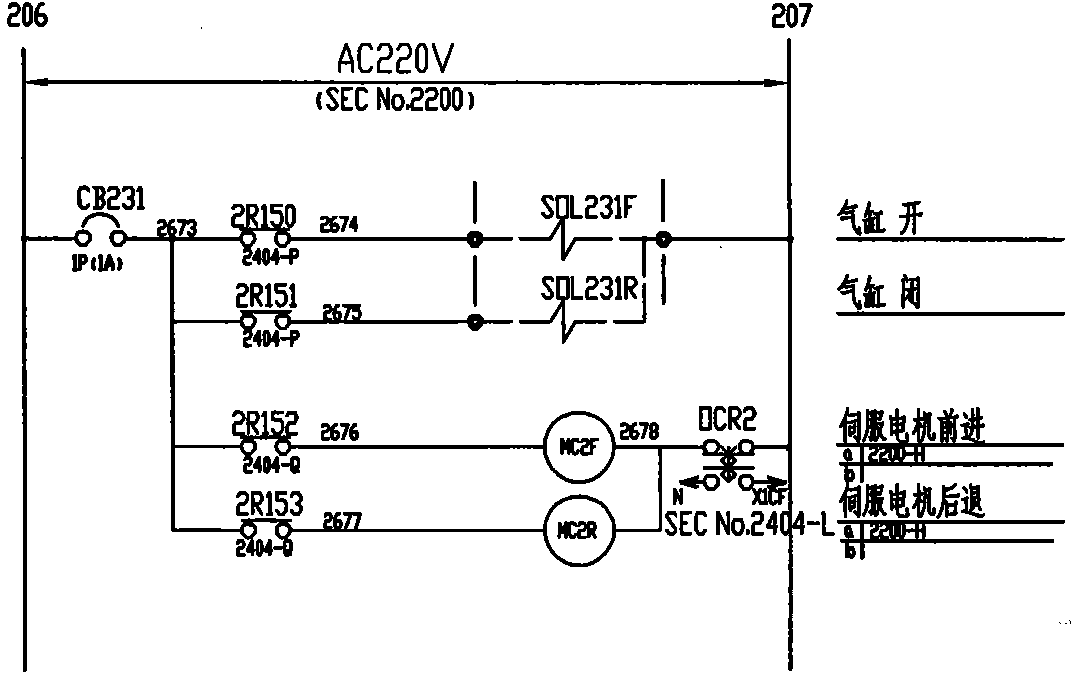

[0026] The present invention as figure 1 As shown, its structure includes an electric control part, a fixed guide rail 1, a moving mechanism and a blocking mechanism, wherein the electric control part includes a PLC control device, a photoelectric switch A8 (a), a photoelectric switch B8 (b), a group of cylinder solenoid valves, A servo motor 2, an electric push cylinder 5 and two groups of limit switches 4, the photoelectric switch A8 (a) and the photoelectric switch B8 (b) all include a photoelectric transmitter and a photoelectric receiver; the moving mechanism includes a moving guide rail 6, When moving the material plate 7 and moving the support beam 3, the blocking mechanism includes blocking the swing arm 14, the cylinder 12, the active swing arm 13, the base 11 and the swing arm shaft 9; the connection relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com