Stabilizer bar conveying and clamping device

A transmission device and stabilizing bar technology, which is applied in the field of stabilizing bar transmission and clamping devices, can solve problems such as prone to safety accidents and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

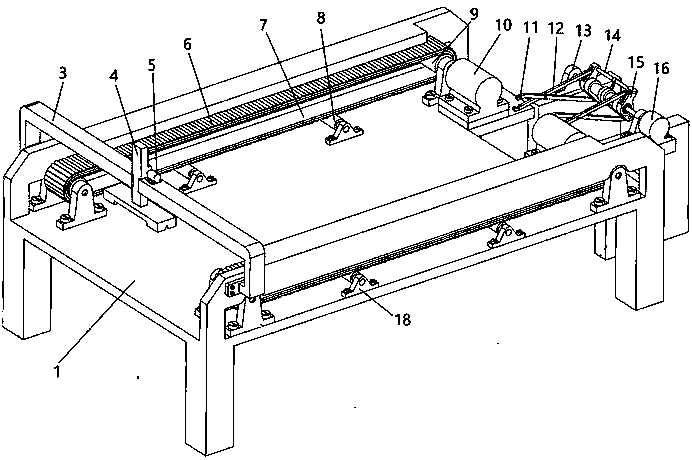

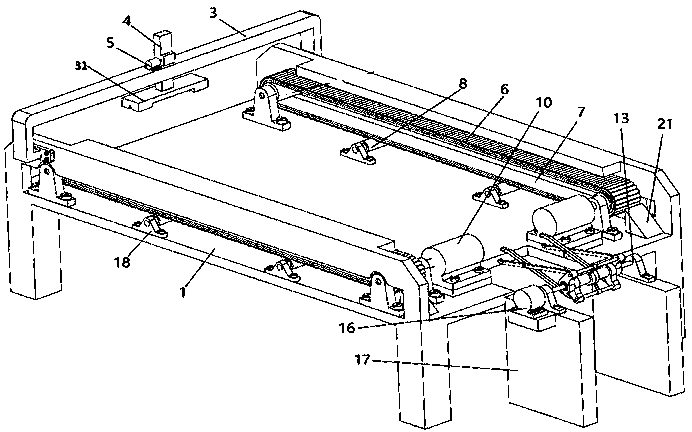

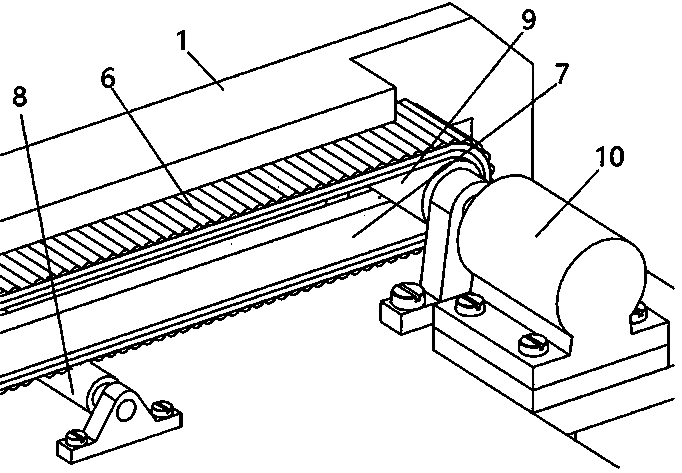

[0020] Example 1. As figure 1 Shown, a kind of stabilizing rod conveying clamping device, it comprises conveying base 1, is provided with vertical baffle plate on both sides of conveying base 1, is provided with conveying device on conveying base 1, described conveying device comprises On both sides of the transmission base 1, there are supporting bases II18 evenly arranged on both sides. On the supporting base II18, a drag roller 8 is installed. The motor drum 9 is provided with a conveyor belt heat insulation layer 6 on the outside of the conveyor belt 7, and the outside of the conveyor belt heat insulation layer 6 is provided with protrusions arranged seamlessly; a straightening device is respectively provided at the head end and the tail end of the transmission device and clamping device; the straightening device includes a crossbar 3 provided on the transmission base 1, a groove I is provided in the middle of the crossbar 3, and a straightening column 4 and a straightenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com