Patents

Literature

44results about How to "Reduce manual links" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

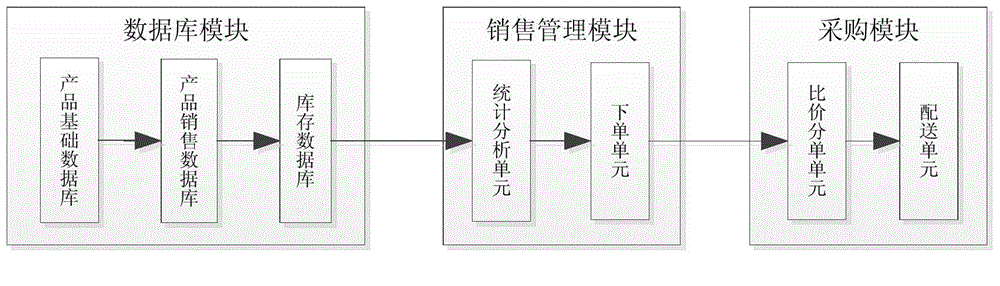

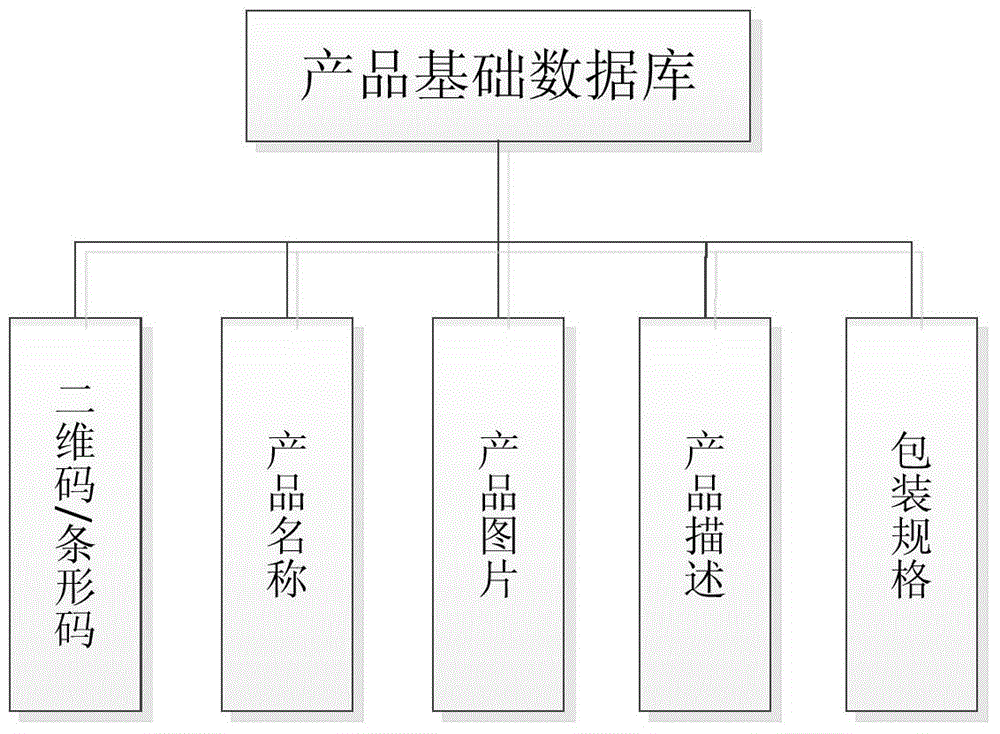

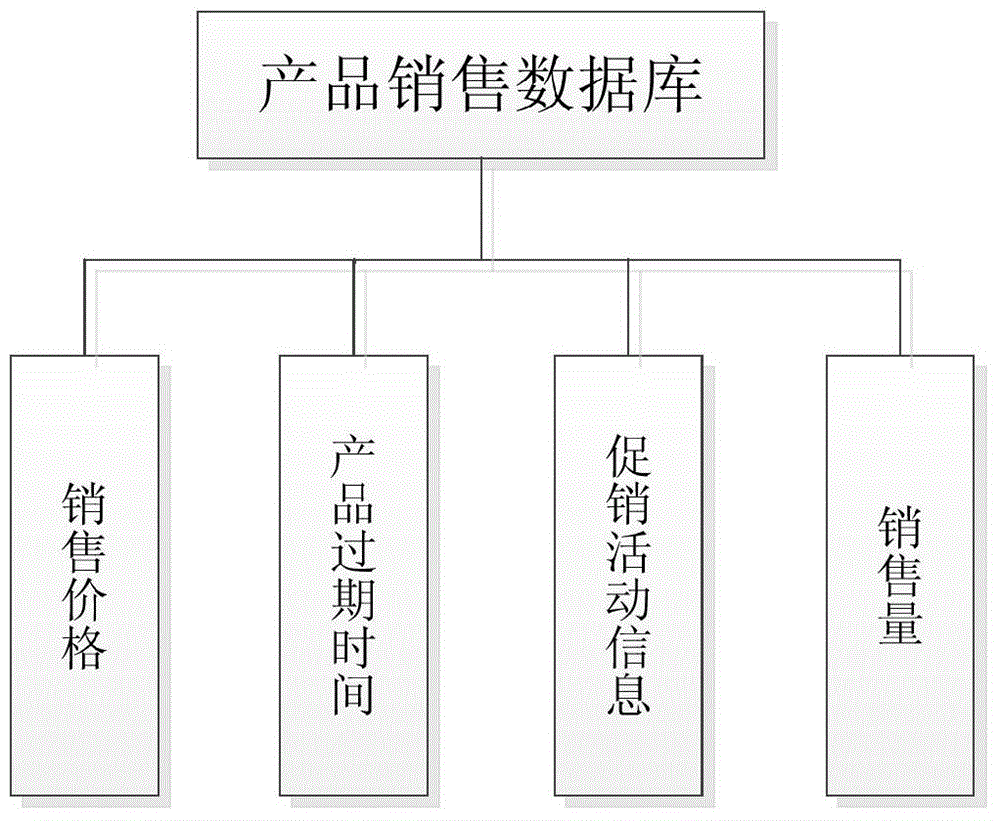

Supermarket integrated management system

InactiveCN104424541AQuick orderQuick low price orderLogisticsOperations researchIndustrial engineering

The invention provides a supermarket integrated management system. The supermarket integrated management system includes a database module used for storing the information of goods, a sale management module which is used for performing timely statistics on the sale quantity of the goods and making a purchase list of goods required to be purchased when the sale quantity of the goods is lower than a predetermined value and making an order-placing decision according to the purchase list, and a purchase module which is used for purchasing goods according to the order-placing decision and performing line distribution allocation according to the purchased goods. With the supermarket integrated management system adopted, online purchase and sale management from manufacturers, dealers, supermarket to terminal consumers can be realized; manual links can be decreased; a working process can be shortened; cost can be reduced; rapid goods ordering with lower prices can be facilitated for the supermarkets; and work efficiency can be improved.

Owner:郑昌栋

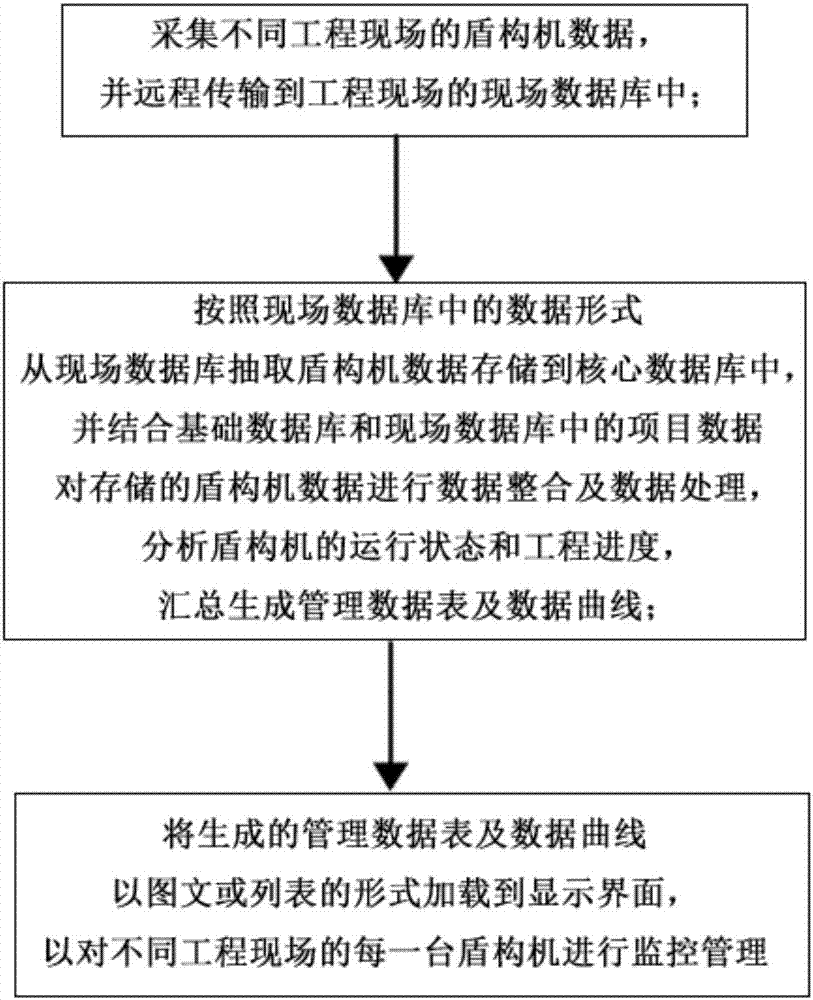

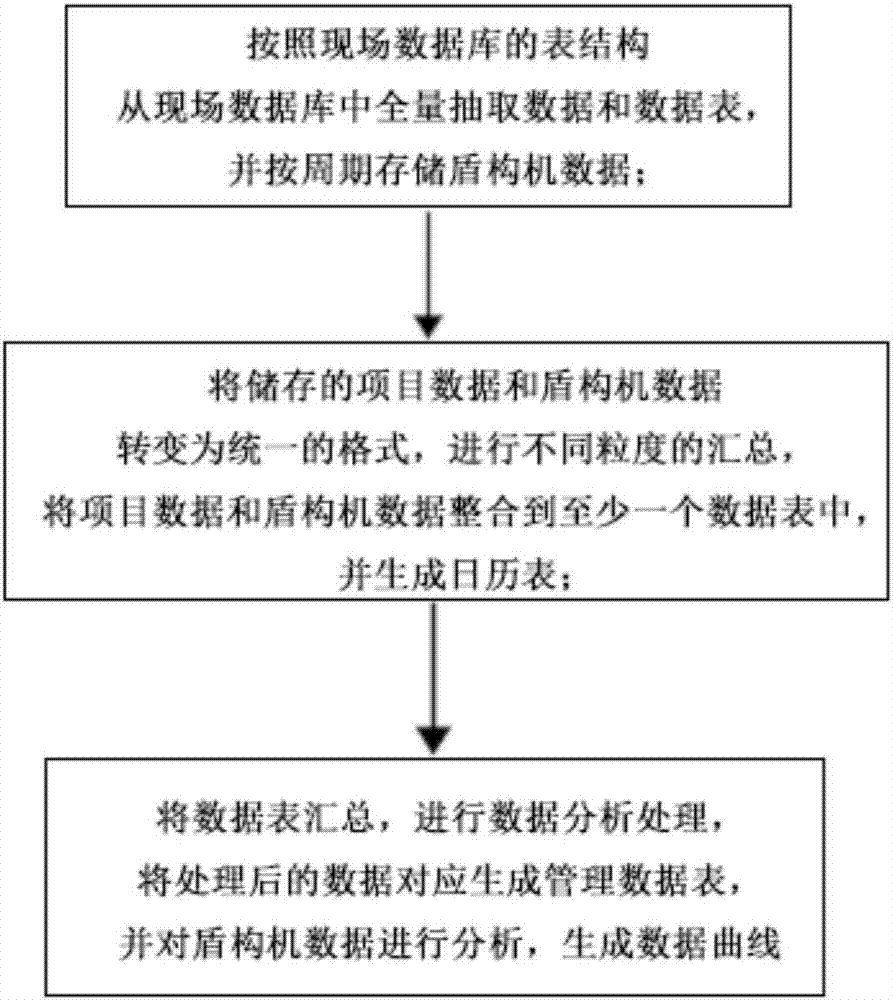

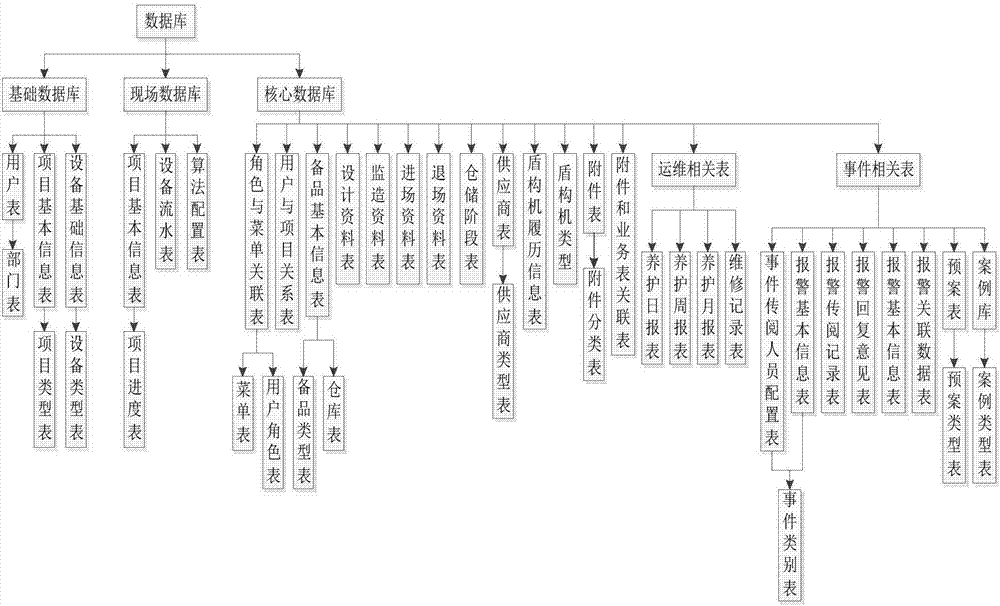

Monitoring and management method for shield machines

InactiveCN107194601AReal-time intelligent managementComprehensive intelligent managementResourcesField dataIntelligent management

The invention relates to the field of shield machine monitoring technology, in particular to a monitoring and management method for shield machines. The method comprises the steps that S1, shield machine data on different engineering fields is collected and remotely transmitted to a field database of the engineering fields; S2, the shield machine data is extracted from the field database according to a data form in the field database and stored into a core database, data integration and data processing are performed on the stored shield machine data in combination with project data in a basic database and the field database, the operating state of the shield machines and progress of works are analyzed, and summarization is performed to generate a management data table and a data curve; and S3, the generated management data table and data curve are loaded to a display interface in the form of image-texts or lists so as to perform monitoring and management on each shield machine on different engineering fields. Therefore, construction time is shortened, a large quantity of manual links are reduced, engineering cost is lowered, working efficiency is improved, and finally real-time comprehensive intelligent management of the shield machines is realized.

Owner:SHANGHAI INST OF TECH

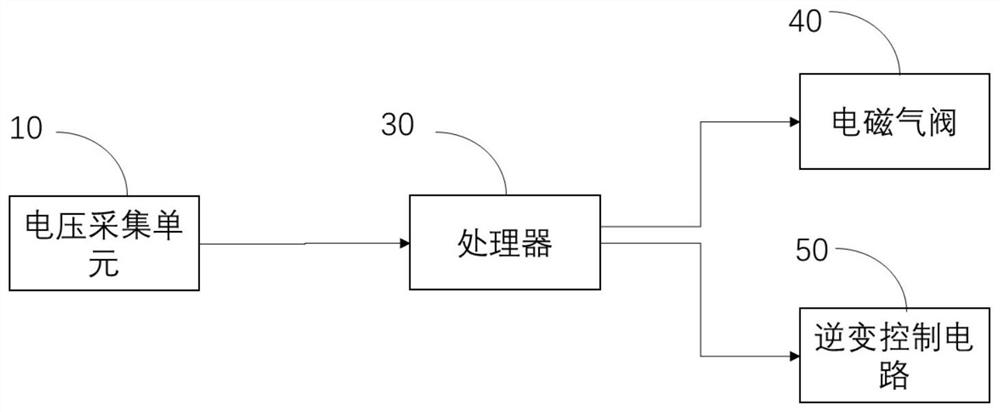

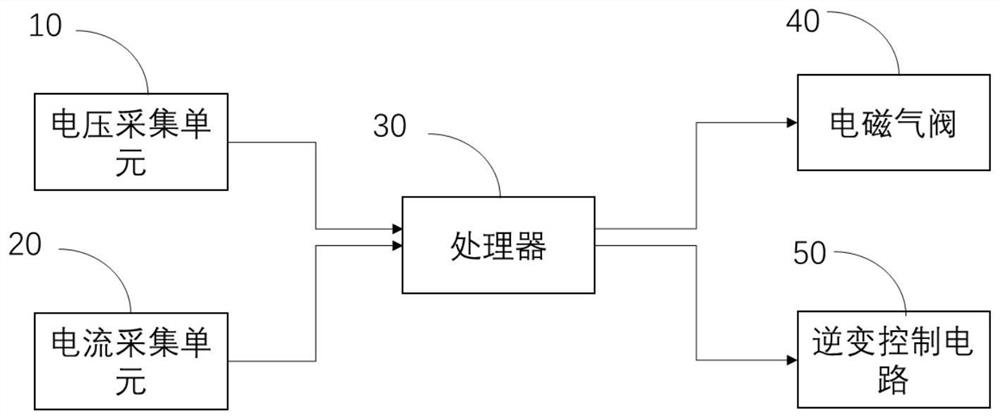

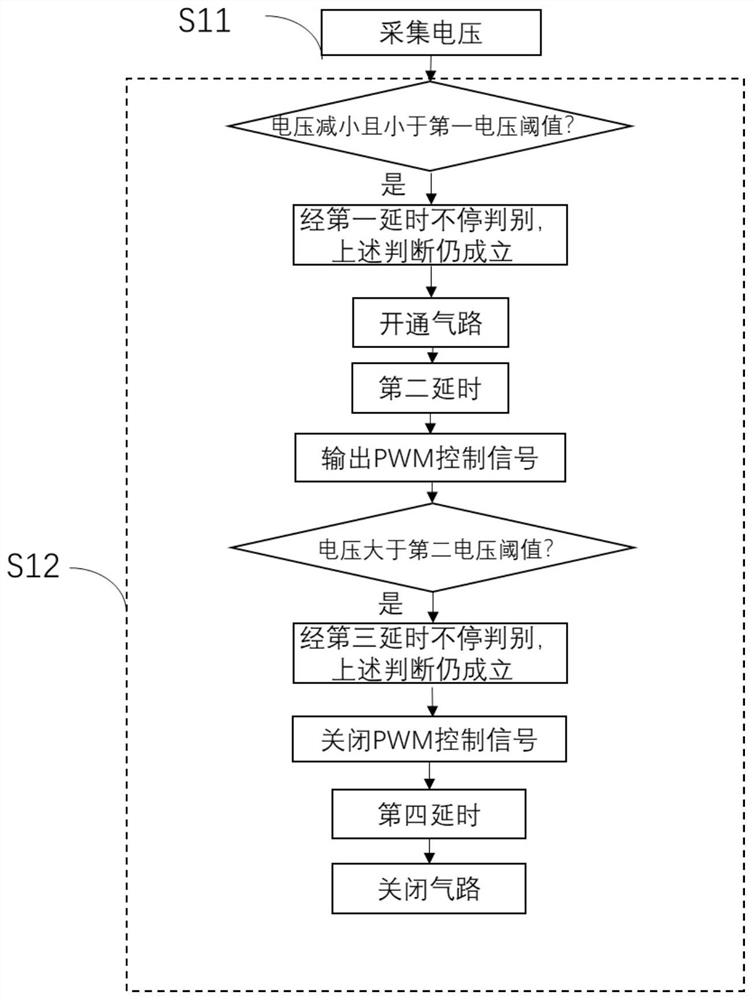

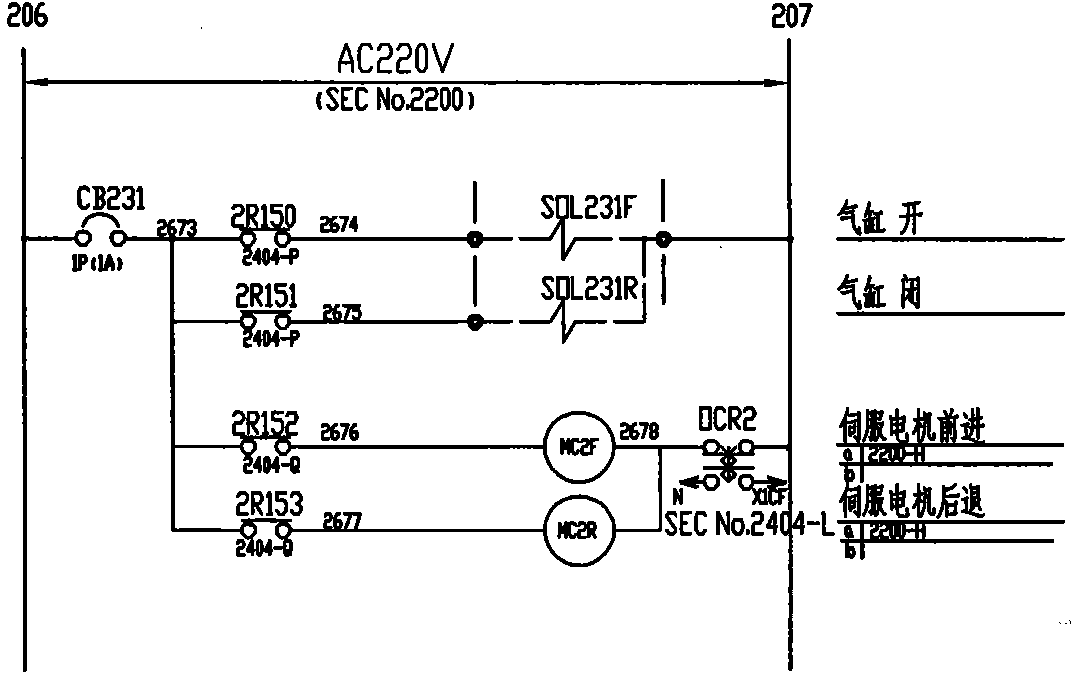

Gas circuit control system and method for argon arc welding machine

ActiveCN113319402AImprove the level of intelligenceAvoid rising costsShielding gas supply/evacuation devicesControl systemControl engineering

The invention discloses a gas circuit control system and method for an argon arc welding machine. The voltage of the argon arc welding machine is collected through a voltage collecting unit, an electromagnetic gas valve and an inversion control circuit are controlled through a processor according to the voltage, opening and closing of a gas circuit of the argon arc welding machine are controlled through the electromagnetic gas valve, and the voltage and current of the argon arc welding machine are controlled through the inversion control circuit. The problems that the argon utilization rate is low and machine operation is complex are solved through effective control over the gas circuit, cost rise caused by long-time gas supply after stopping of the welding process is avoided, meanwhile, effective control over the gas circuit is achieved, the manual procedures can be reduced, and the intelligent requirement of the argon arc welding machine is met. According to the gas circuit control system and method for the argon arc welding machine, the argon utilization rate is increased, the operation complexity is reduced, the intelligent level of the argon arc welding machine is improved, and high practical value is achieved.

Owner:SHANGHAI GREATWAY WELDING EQUIP

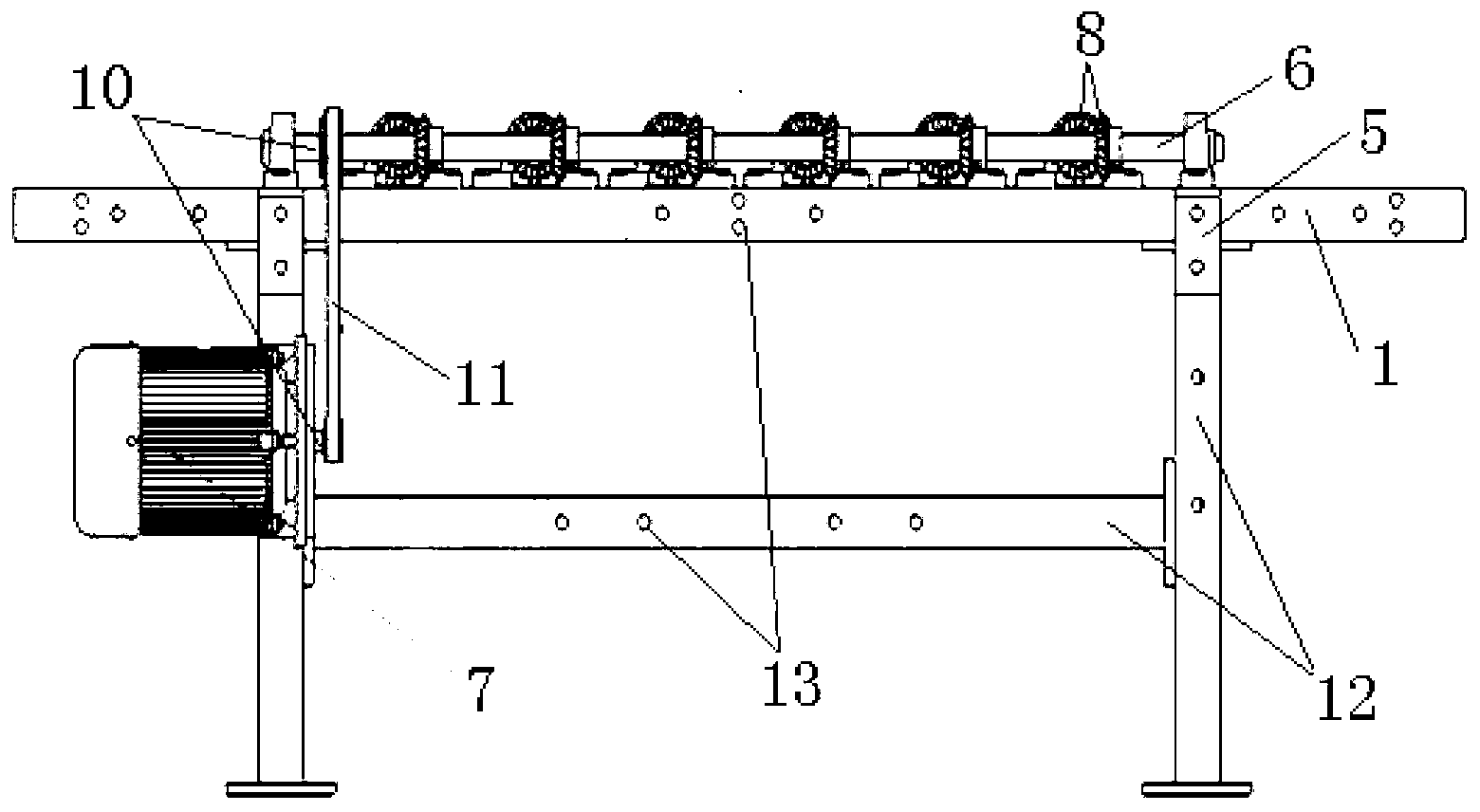

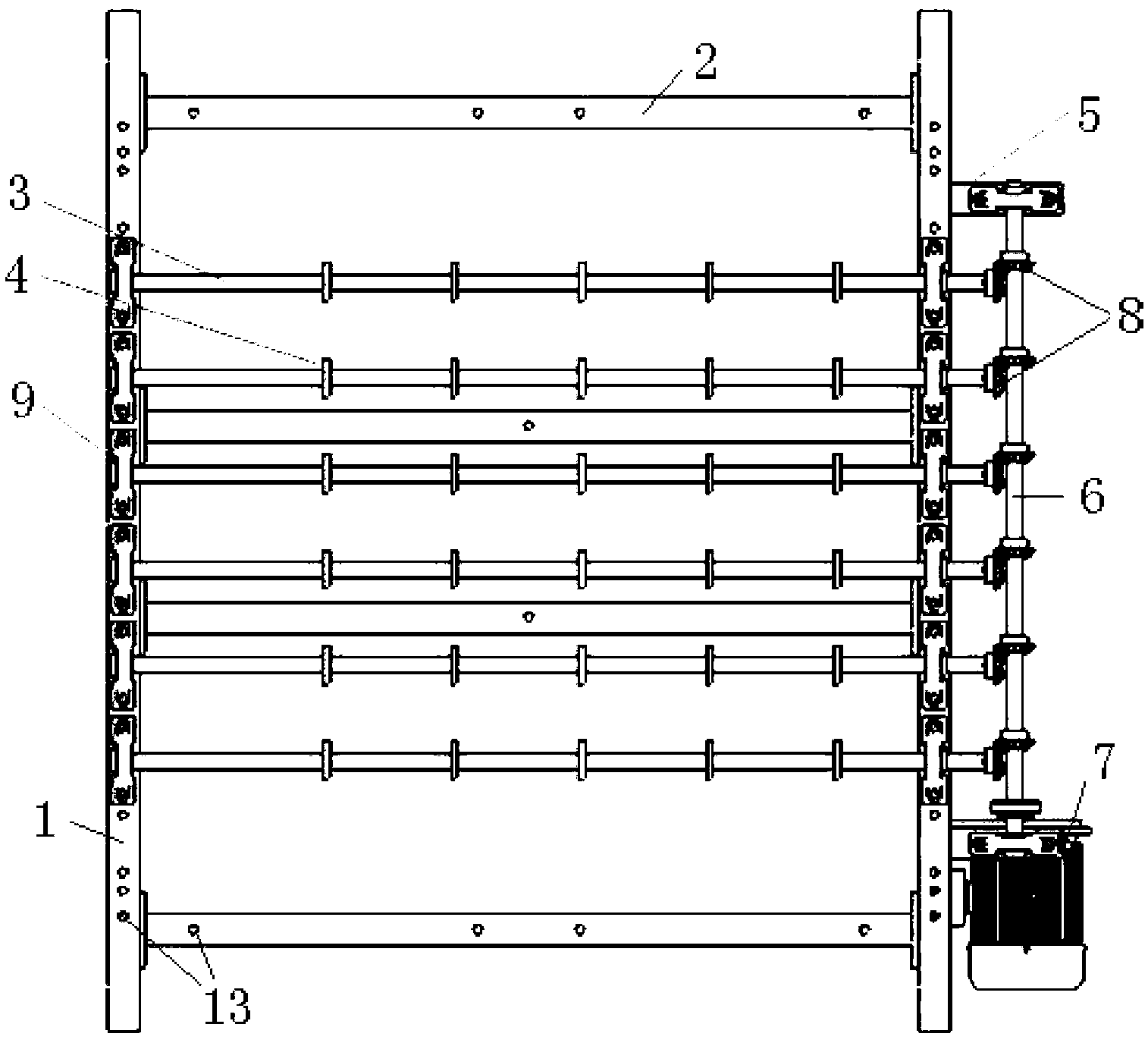

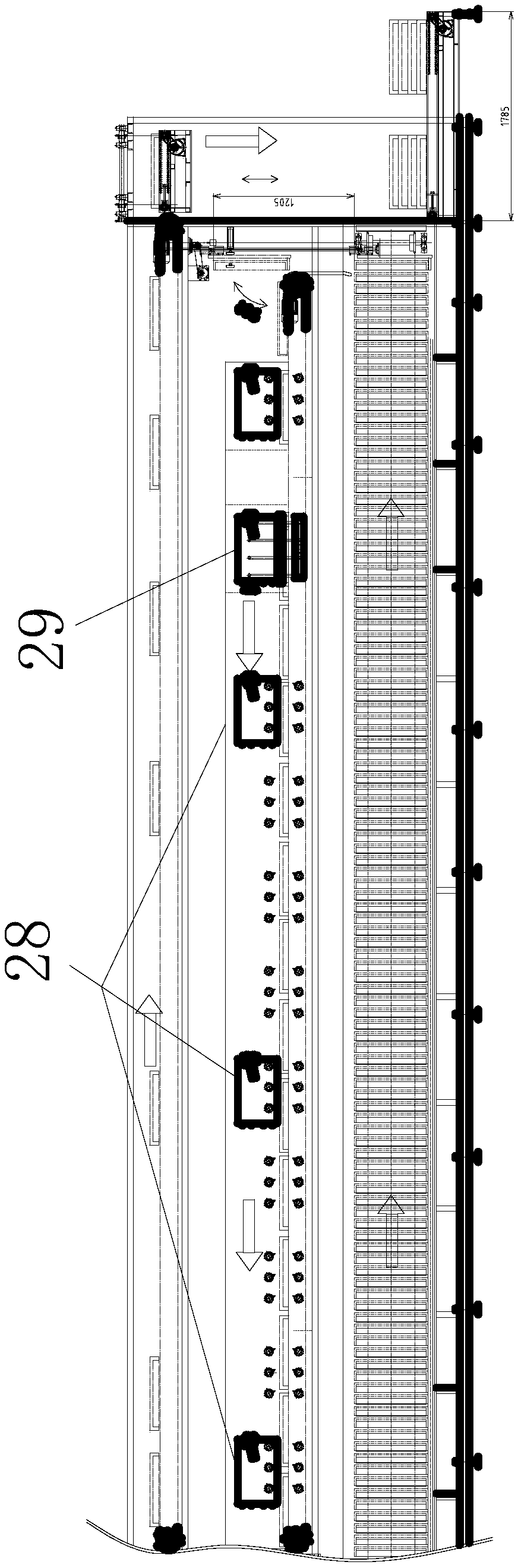

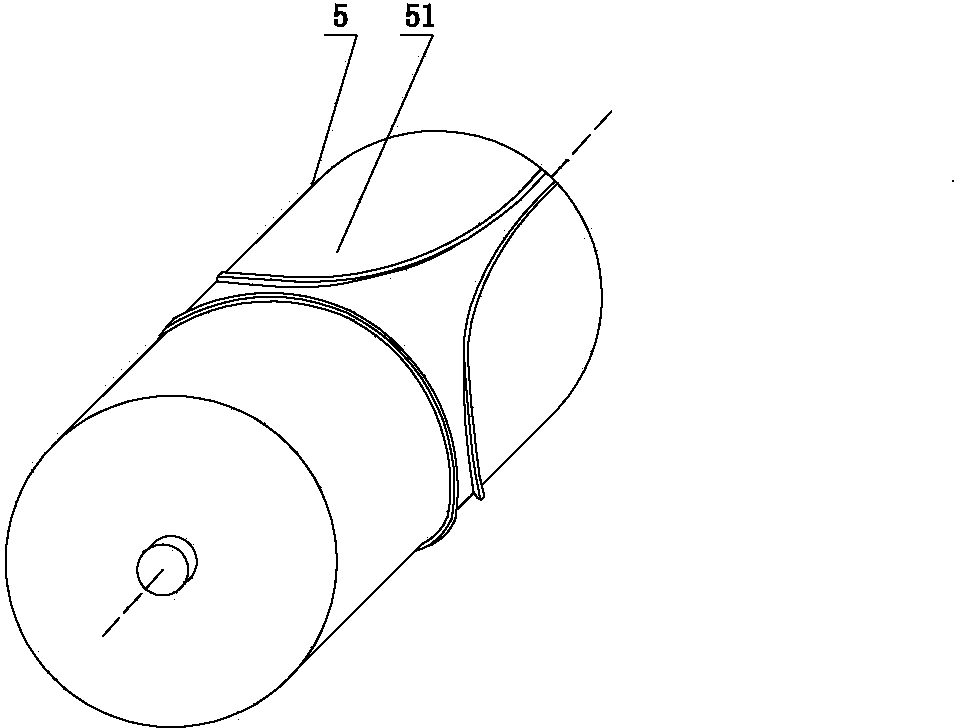

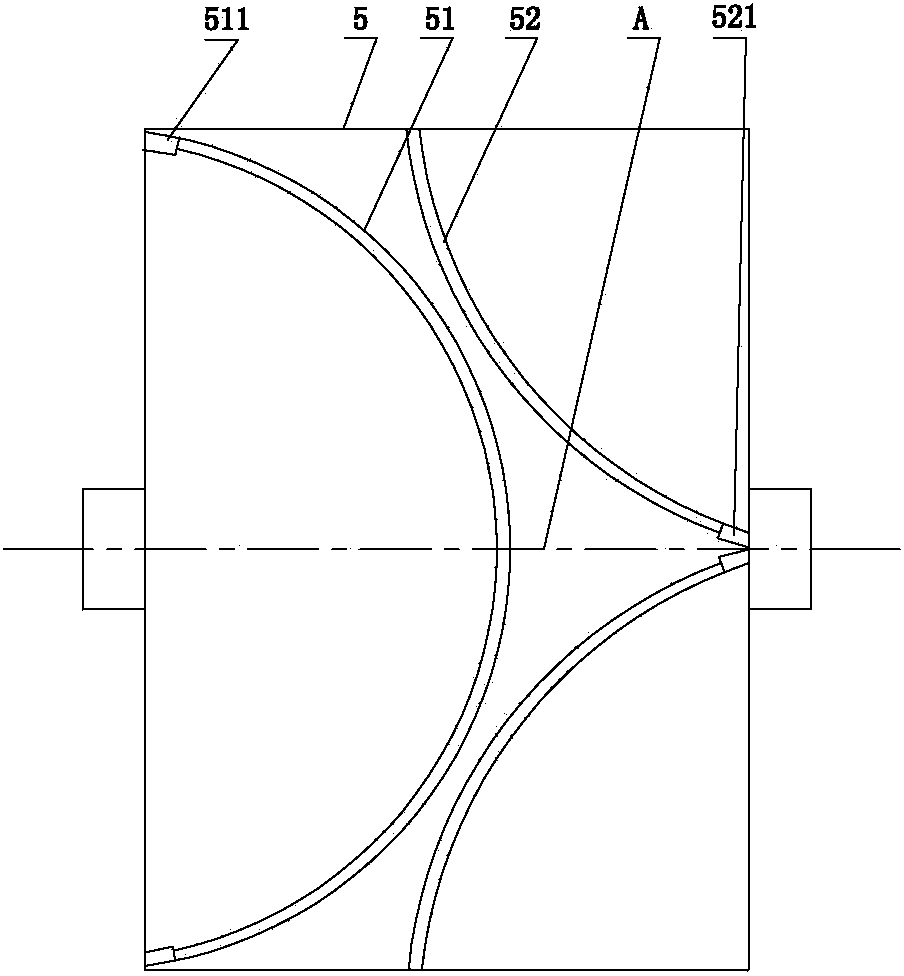

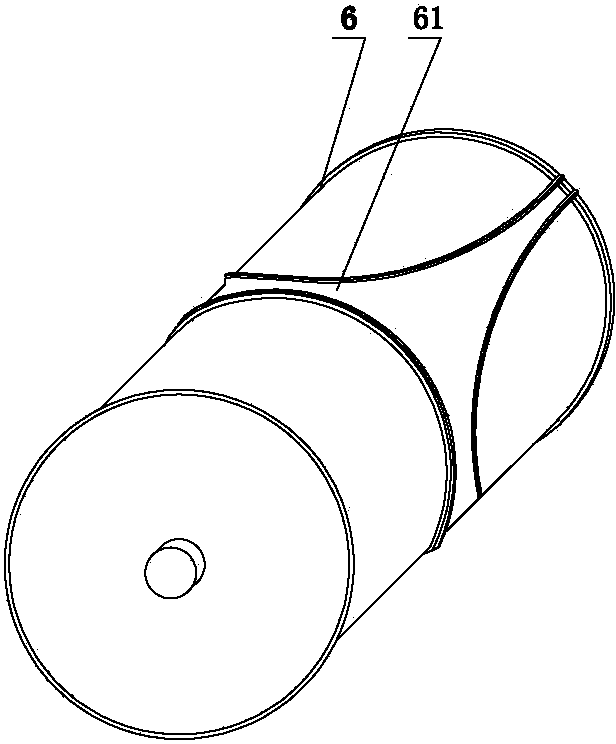

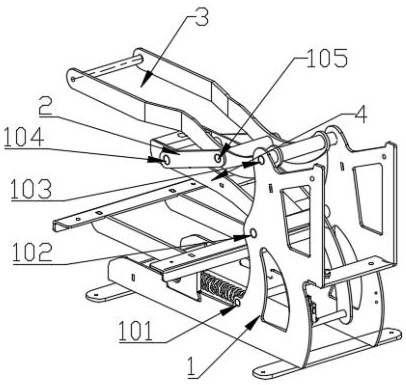

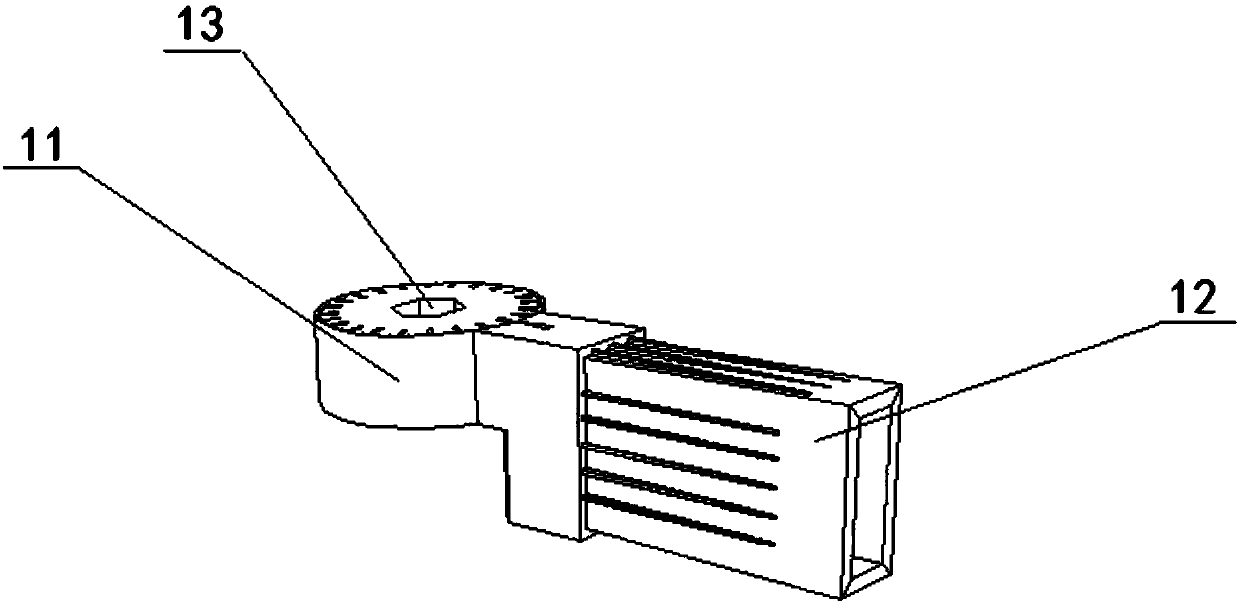

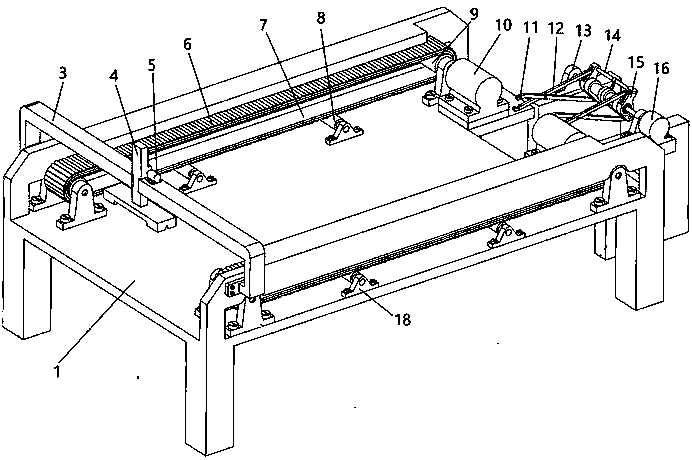

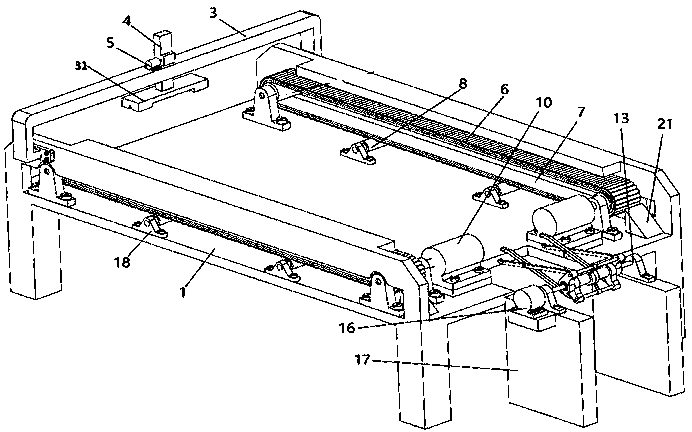

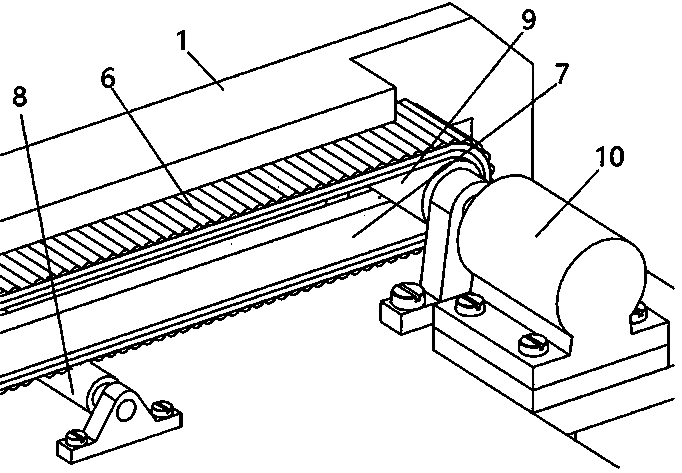

Fixing frame

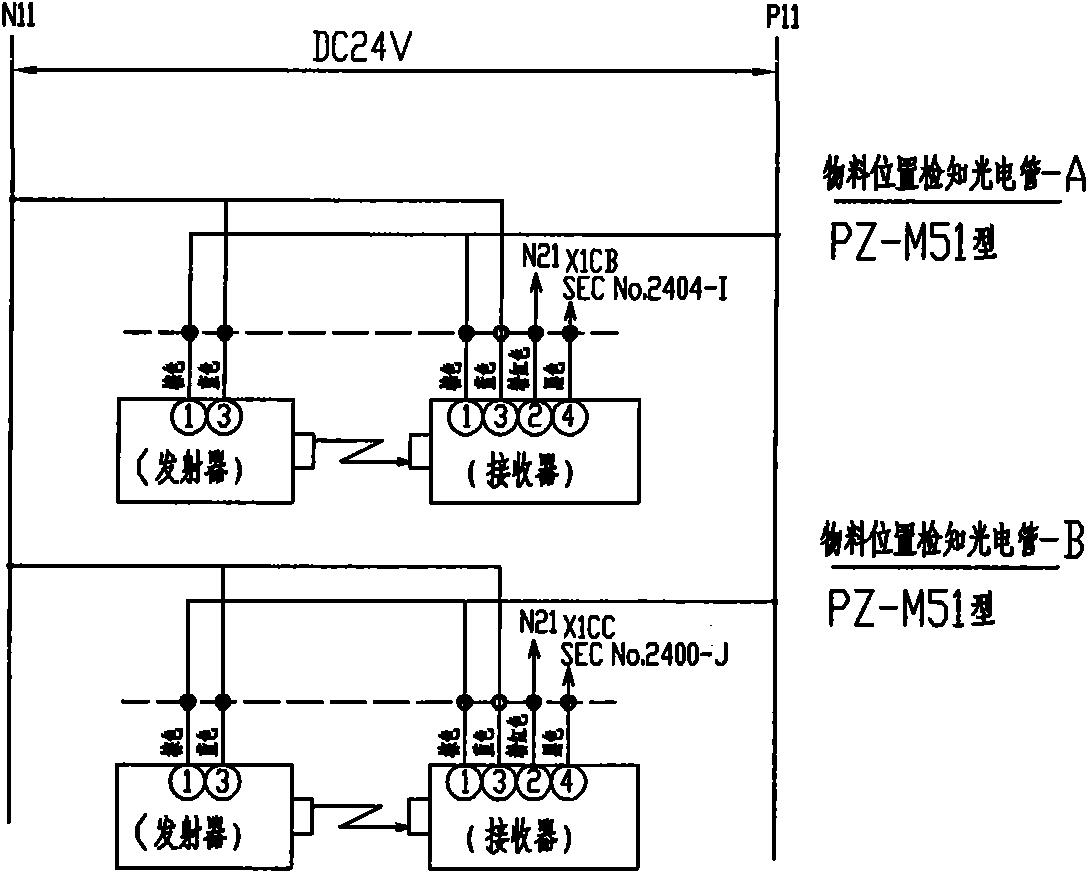

InactiveCN103213804AMeet the installation and placement requirementsReduce manual linksRollersRoller-waysFixed frameEngineering

The invention discloses a fixing frame which comprises support straight rods and support cross rods, wherein the at least two support cross rods are fixed between the at least two support straight rods at equal interval; at least two carrier rollers are also arranged between the at least two support straight rods; each carrier roller is provided with at least two support wheels at equal interval; a bearing seat bracket is arranged at one side of each support straight rod; a driving roller is fixed on the bearing seat bracket; one end of the driving roller is connected with a driving motor; and the driving rollers are respectively connected with the carrier rollers by bevel gears which are in occlusion with each other. A transmission power system is provided for conveying, so that the artificial link in the delivering and conveying process can be reduced, the unnecessary loss is reduced, and the brittle material can be delivered and conveyed in a pure mechanical way; an installation and placement platform is provided for large machines and devices used for pretreating the brittle material, so that all processing devices can be comprehensively operated by a single person, the manpower occupation is reduced, and the occupied space is small; and the fixing frame is wide in applicability, and can widely meet the installation and placement requirements of pretreatment of different types of brittle materials.

Owner:HUNAN SANXING LEIYANG GLASS MACHINERY

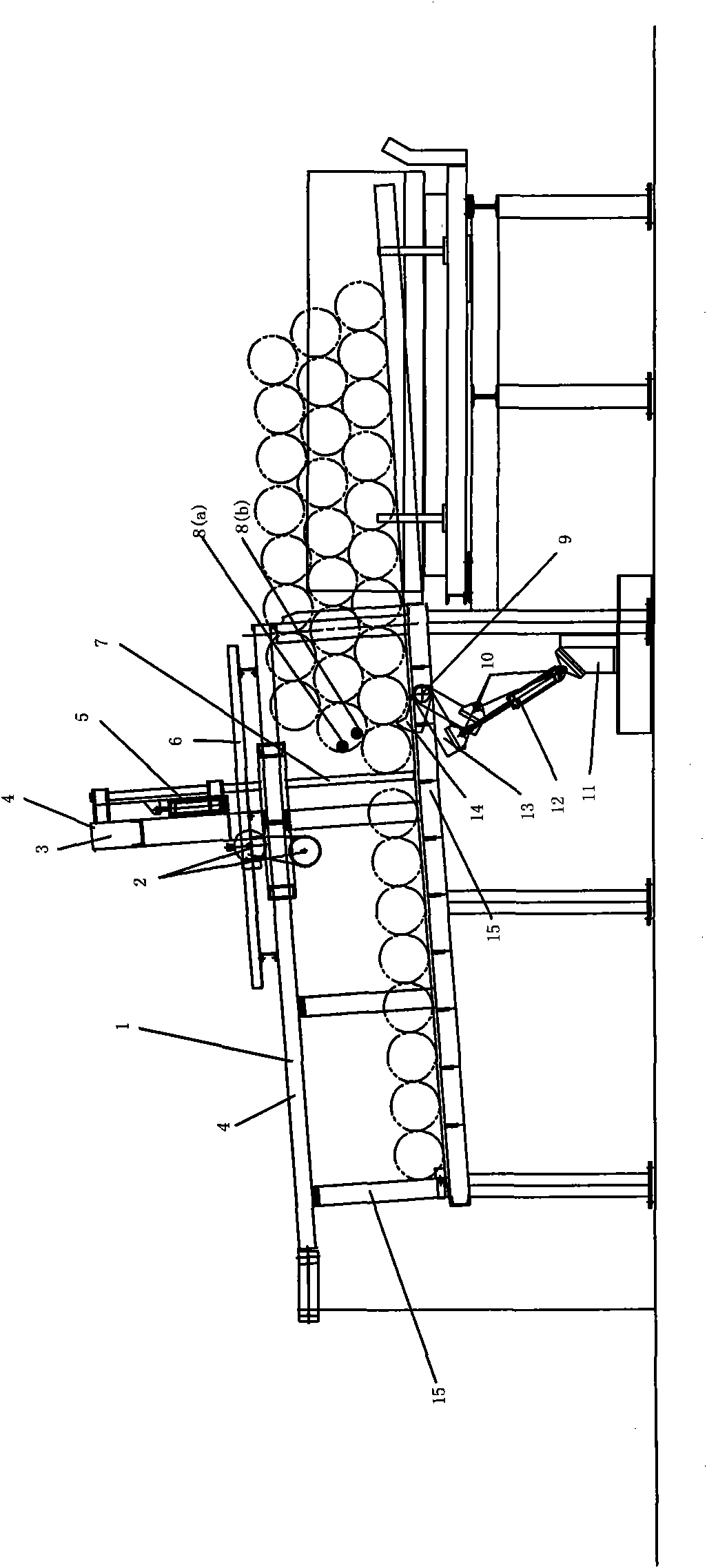

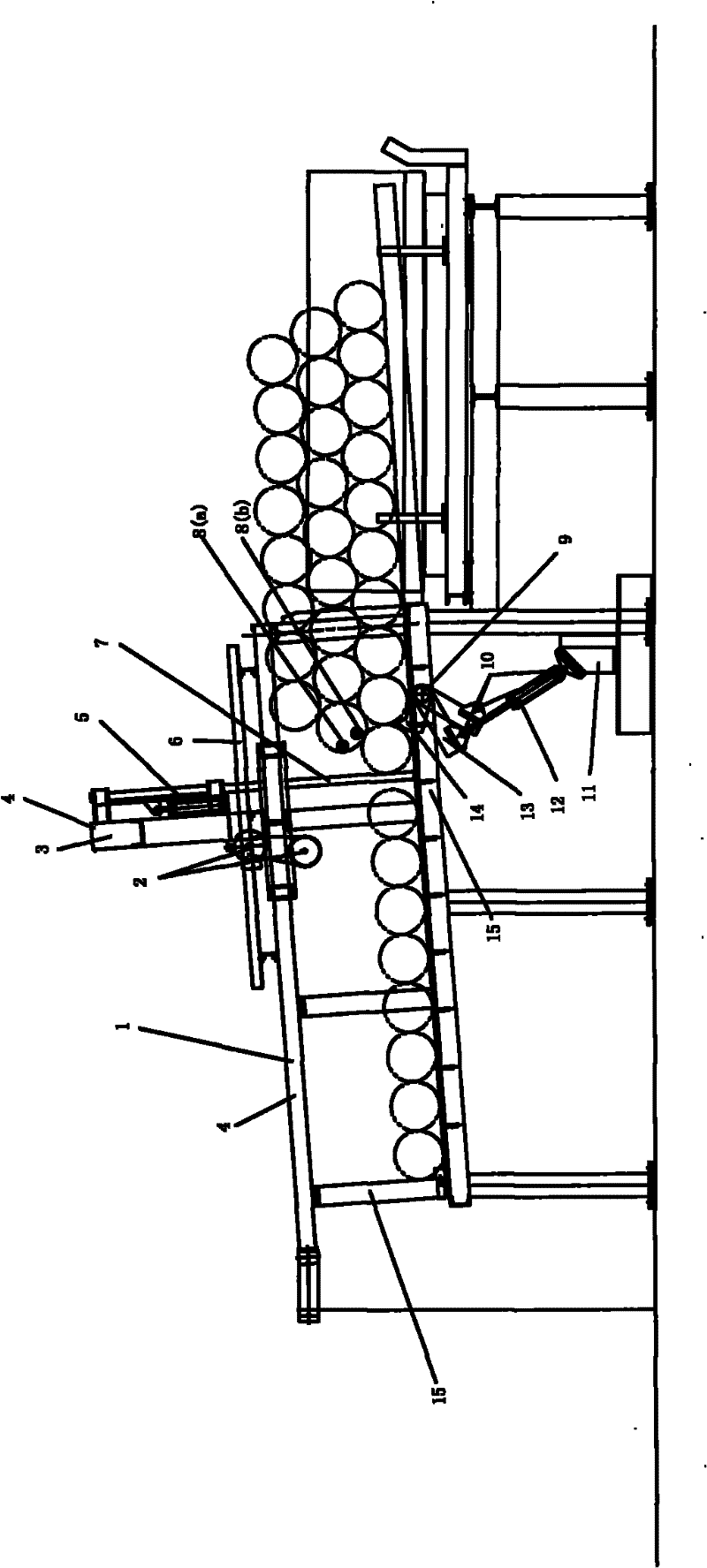

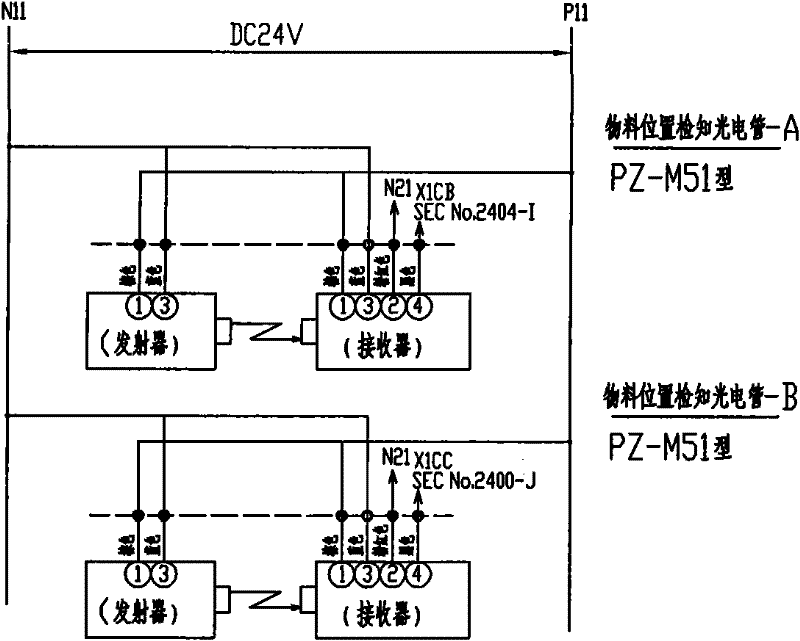

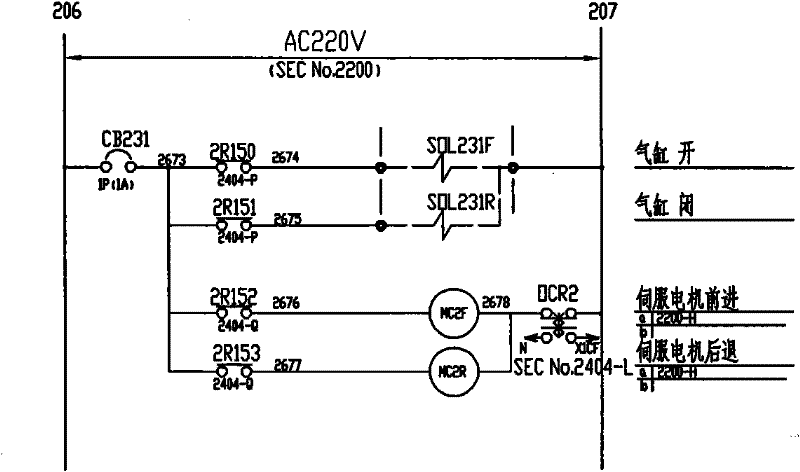

Metal bar material conveying device and application method thereof

ActiveCN101786545AReduce manual linksAutomated process extensionControl devices for conveyorsCharge manipulationAlloyEngineering

The invention relates to a metal bar material conveying device and an application method thereof, belonging to the technical field of alloy production raw material conveying machinery. The device comprises an electric control part, a fixed guide rail, a moving mechanism and a blocking mechanism; and the application method of the device enables the device to achieve the function of controlling the speed of materials in the first row and discontinuously actuating materials in the second row and the whole material pile thereafter. By organically combining the supplied material conveying and the automatic feeding, the device omits the intermediate manual link, extends the automation procedure, can simultaneously be extended to other industries in which the automatic bar material conveying is necessary, and is especially applicable to the bar material of which the ratio of length to diameter is less than 2.

Owner:SHENYANG NEU-SANKEN IND FURNACE MFG CO LTD

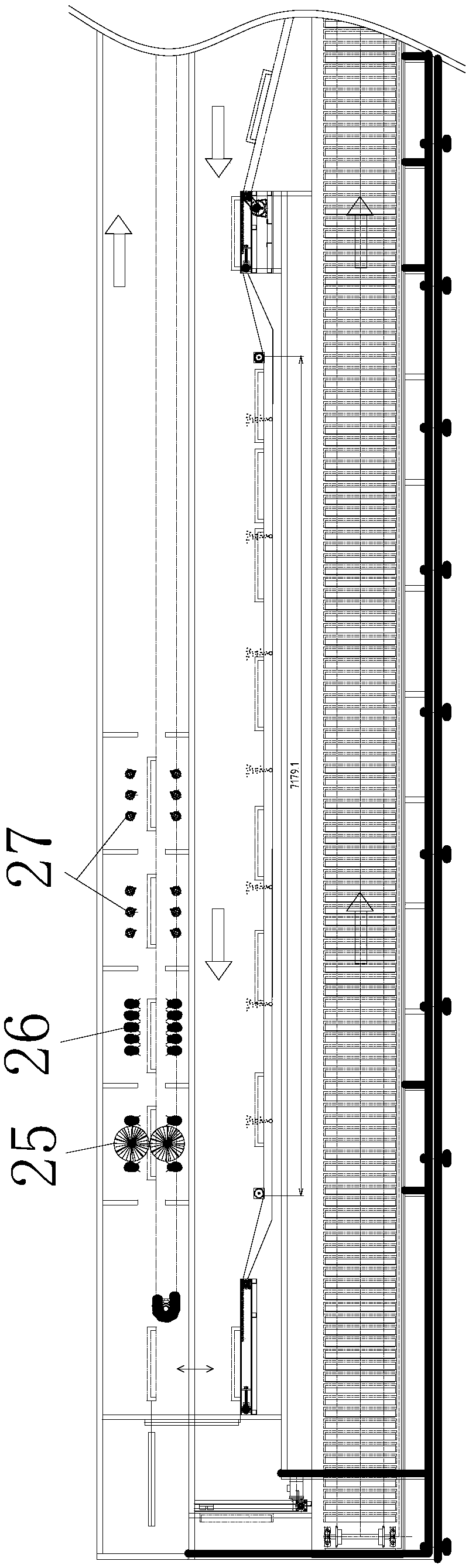

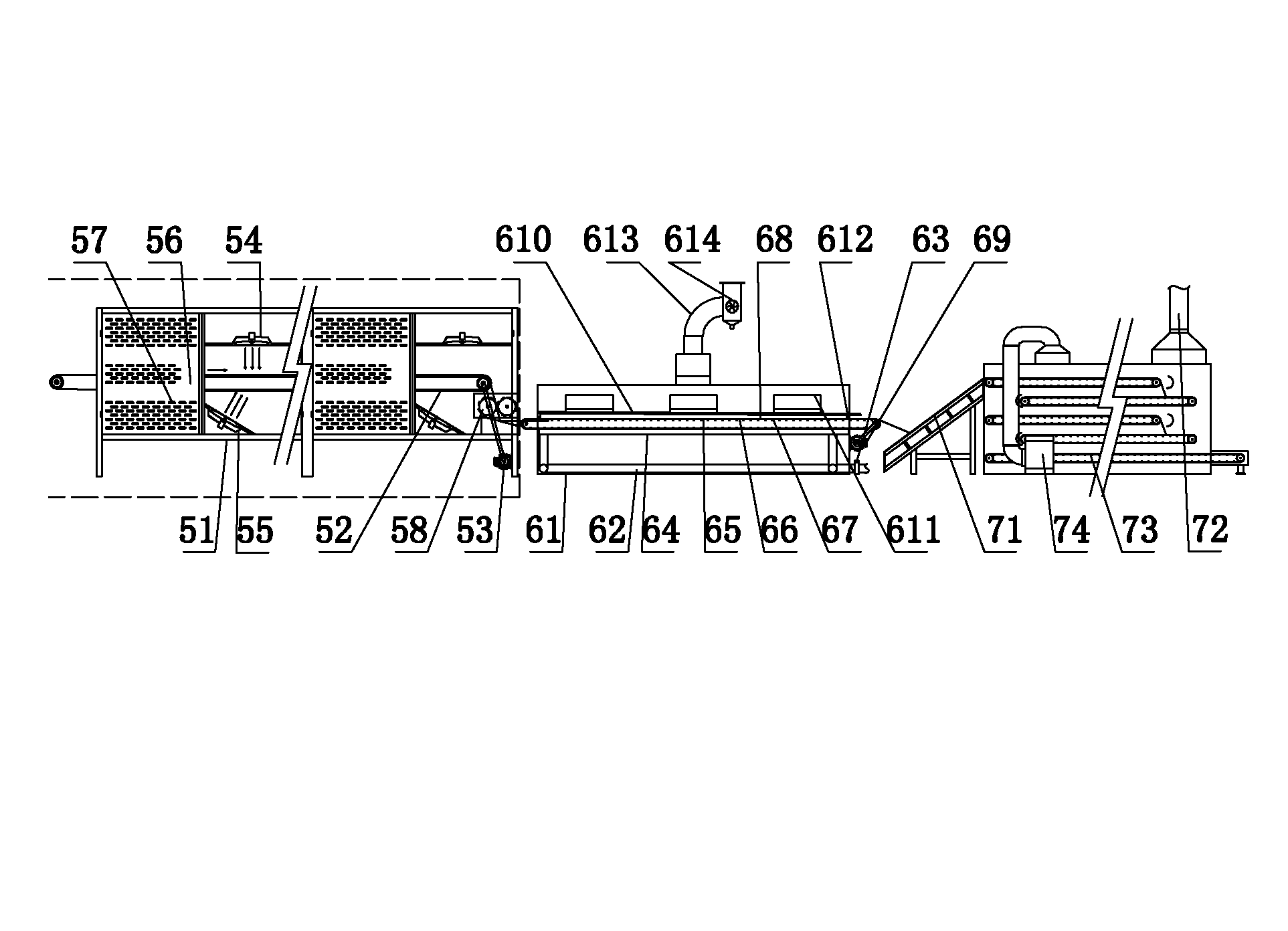

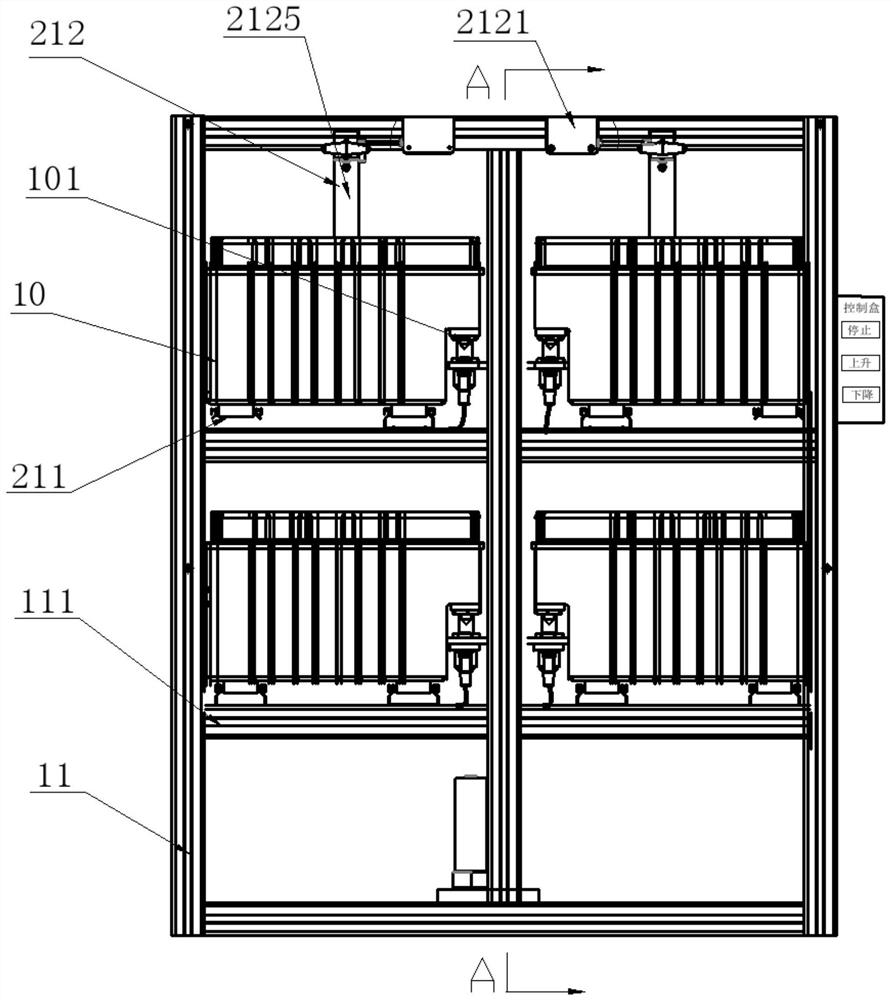

Cleaning and sterilizing device for feeding frame of Babei cocoon cage

PendingCN109226036AImprove cleaning efficiencyReduce manual linksDrying gas arrangementsCleaning using toolsWater cutThermal water

The invention discloses a cleaning and sterilizing device for a feeding frame of a Babai cocoon cage, which comprises a cleaning box and a drying box, wherein the feeding frame in the cleaning box anddrying box is fully automatically transmitted, the cleaning efficiency is high, the cleaning box sequentially includes a first coarse soaking transmission chamber, a high-temperature soaking chamber,a water spraying chamber and a water cutting chamber, surface treatment is performed in the first coarse soaking transmission chamber, soaking and cleaning by using hot water are carried out in the high-temperature soaking chamber, spraying surface treatment and water cutting are carried out in the water spraying chamber and the water cutting chamber, the feeding enters the drying box along a guide tray, soaking and sterilizing are carried out in the first coarse soaking transmission chamber in the drying box. Spraying, washing, sterilizing and drying are carried out in a washing chamber andair cutting chamber in the drying box, and finally the feeding frame is conveyed to a stacking tray on a discharging conveyor belt for discharging through a discharging mechanism, therefore, the feeding frame is cleaned by using a full-automatic cleaning structure, a plurality of manual links are saved, the cost is reduced, the cleaning efficiency is improved, and the cleaning effect is excellentthrough repeated cleaning and sterilizing.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

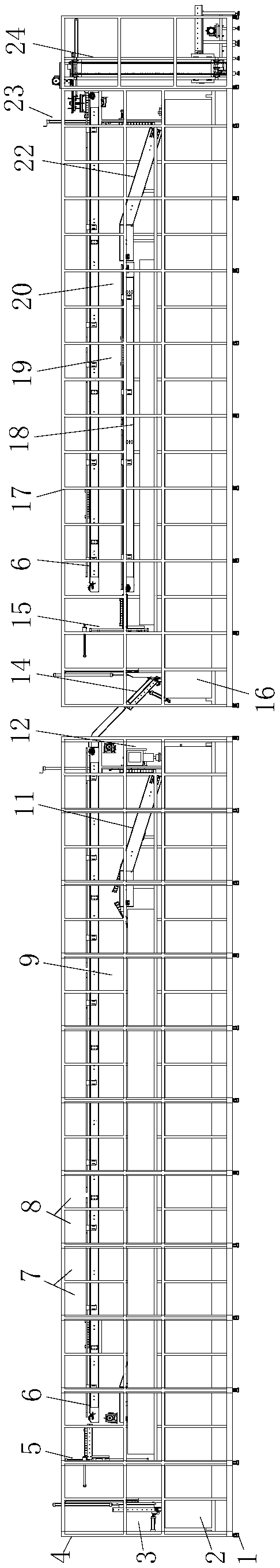

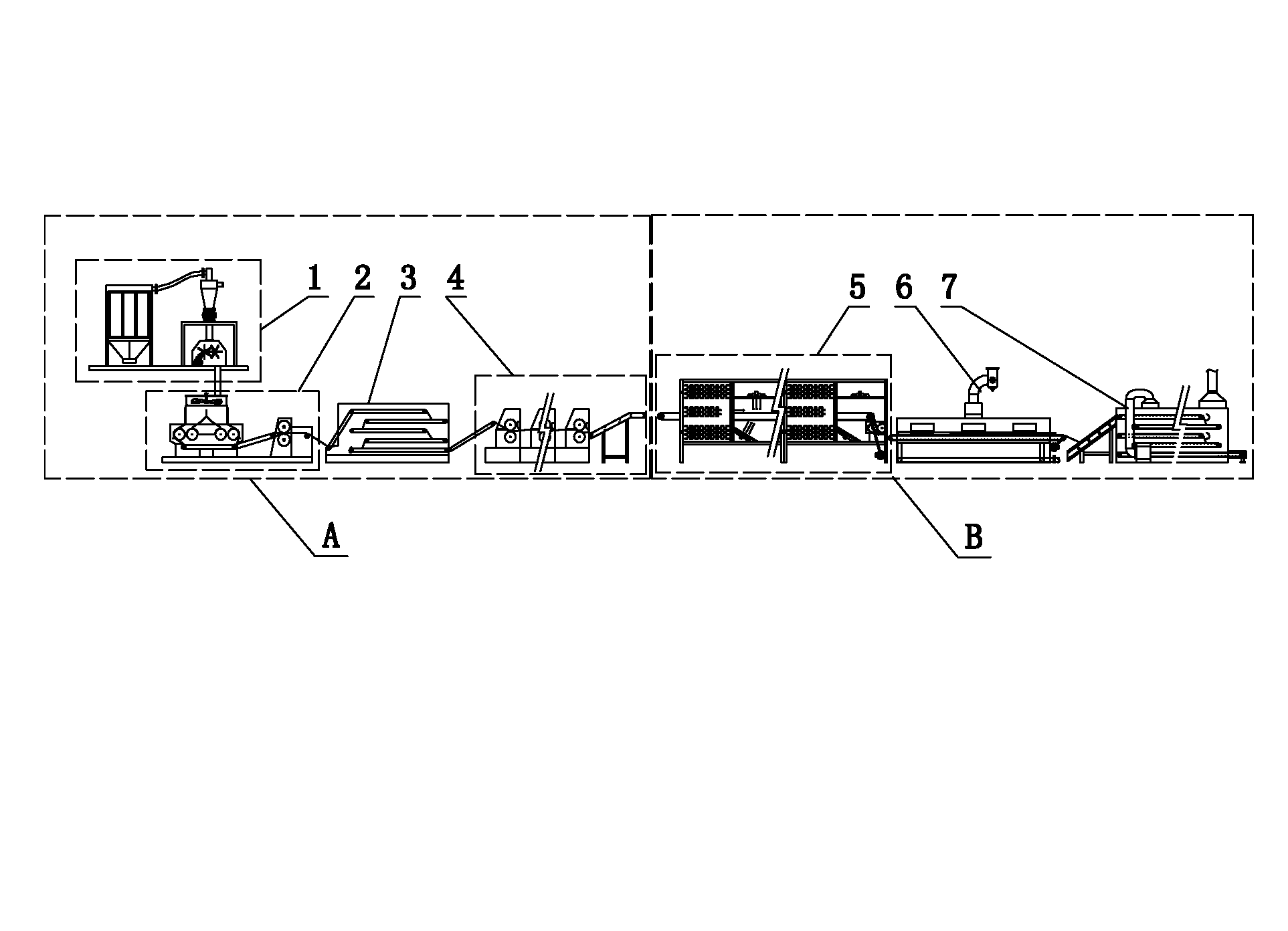

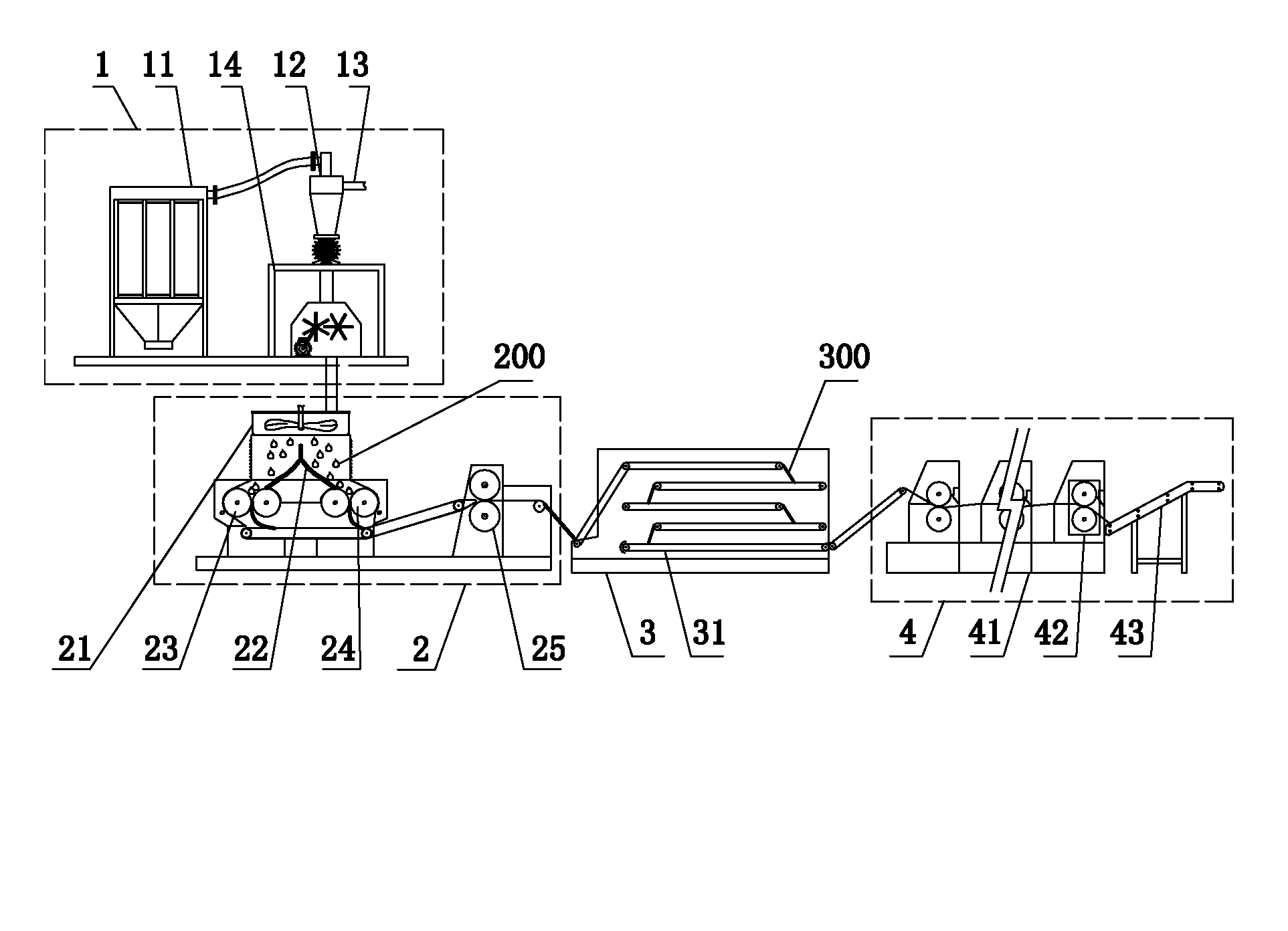

Novel sliced noodle production line

ActiveCN102919687AIncrease contact areaReduced Chances of ContaminationFood preparationHigh concentrationProduction line

The invention discloses a novel sliced noodle production line, which comprises a dough making machine, a wheat belt combining machine, an aging machine, a rolling device, drying devices, and a sliced noodle heating device. The wheat belt combining machine is arranged below the dough making machine; the aging machine is arranged on the right side of the wheat belt combining machine; the rolling device is arranged on the right side of an aging machine; a first drying device is arranged on the right side of the rolling machine; the sliced noodle heating device is arranged on the right side of the first drying machine; and a second drying device is arranged on the right side of the sliced noodles heating device. The production line has the characteristics of high concentration, high automation, high production efficiency, low energy consumption and the like. The novel sliced noodle production line can complete automatic feeding, dough making, combining, rolling, steaming, cutting, drying and other processes. Cut by the dough cutting roll with uniform edge, the noodles are in good shape and easy to pack. The novel sliced noodle production line is very suitable for fast and instant food processing and therefore has a bright market prospect in the industry.

Owner:HUBEI GUDASAO FOOD

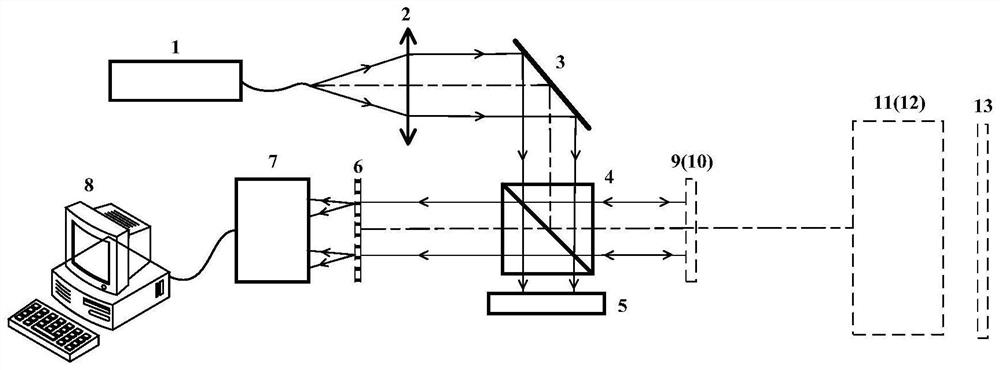

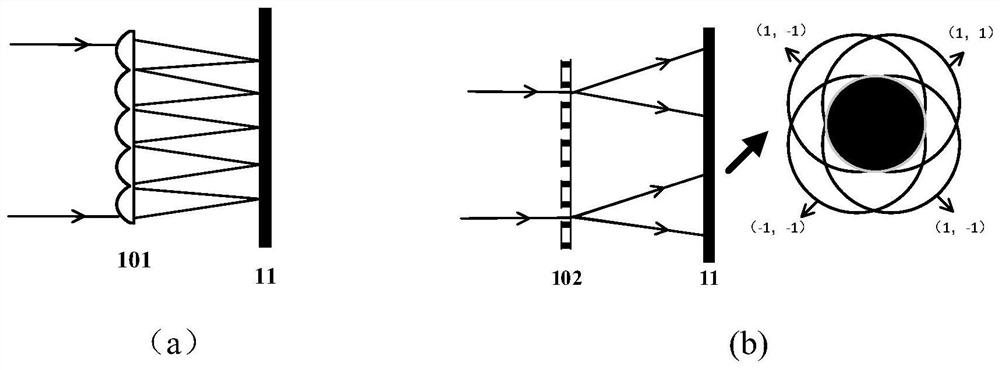

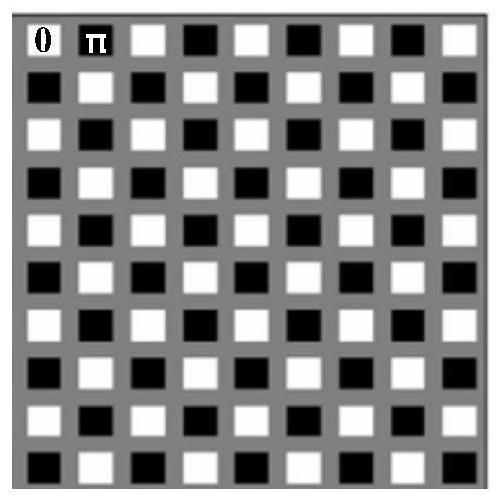

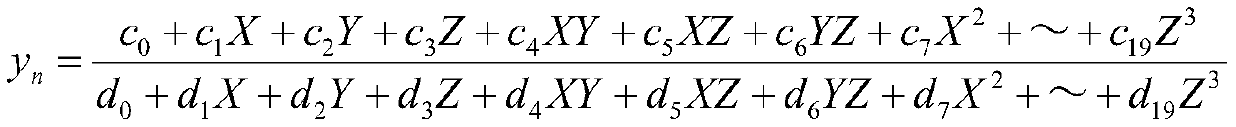

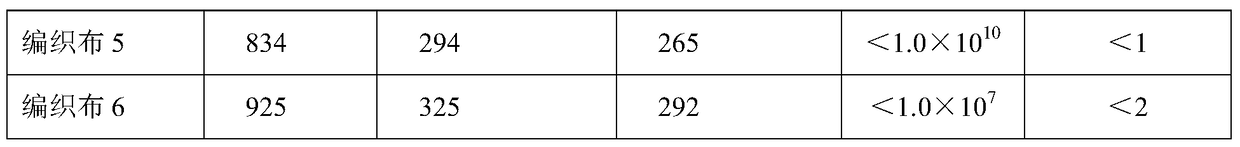

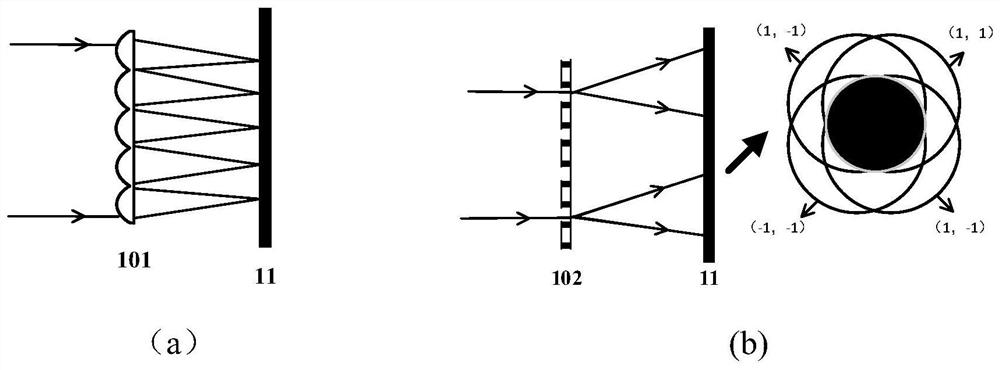

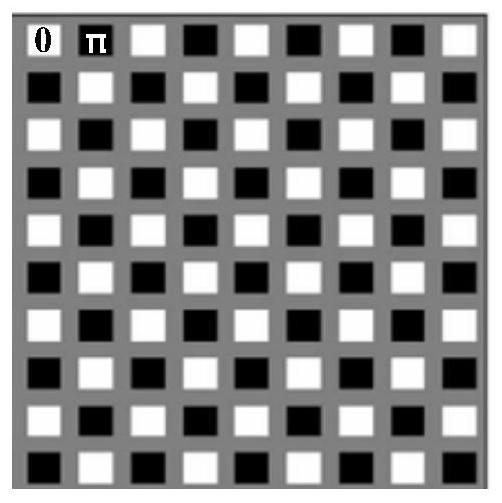

Dynamic high-resolution optical wavefront phase measuring device and measuring method

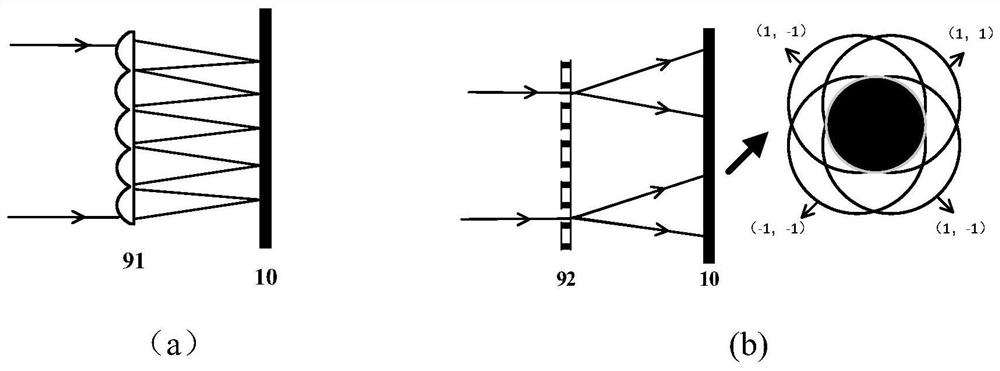

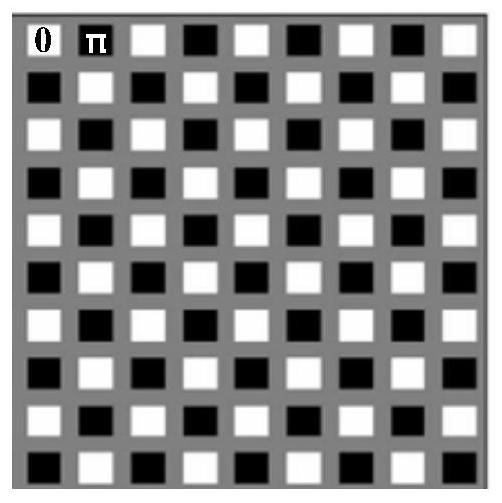

ActiveCN111751012AEnabling Active Optical TestingHigh resolutionOptical measurementsUsing optical meansBeam splitterGrating

The objective of the invention is to solve the technical problems of low precision and low resolution of an existing dynamic optical wavefront phase measurement device. The invention provides a dynamic high-resolution optical wavefront phase measuring device and a measuring method, and the device and the method can achieve the active optical testing of the surface shape of an optical element and the wave aberration of an optical system through a laser, a collimating mirror, a plane mirror, a spectroscope, an absorber, a mixed modulation grating, a detector, a computer, different F # standard lenses, and a calibration mirror. The resolution is determined by the size of a detector pixel, high-resolution optical wavefront phase measurement can be achieved, and the resolution can be smaller than 0.01 mm. According to the method, a system background error is used as system data after being calibrated once, and the measured surface topography information can be calculated only by collectingan image once during actual surface shape measurement, so that compared with the traditional phase shift interference method, the method is not influenced by environments.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

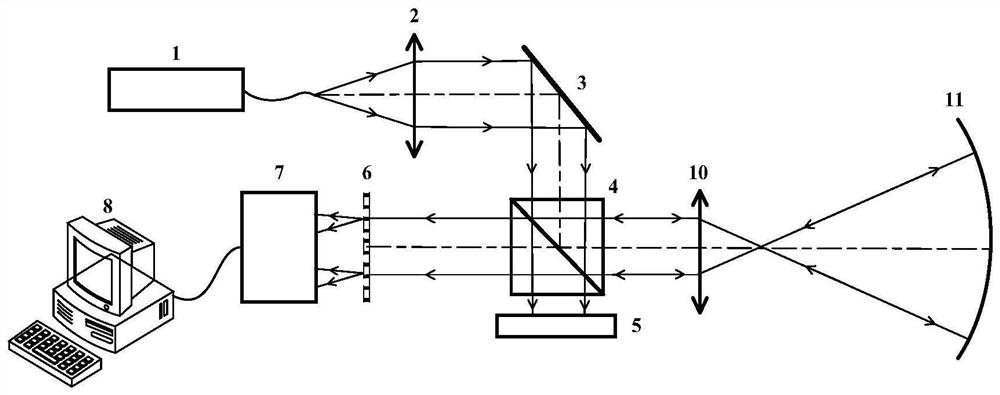

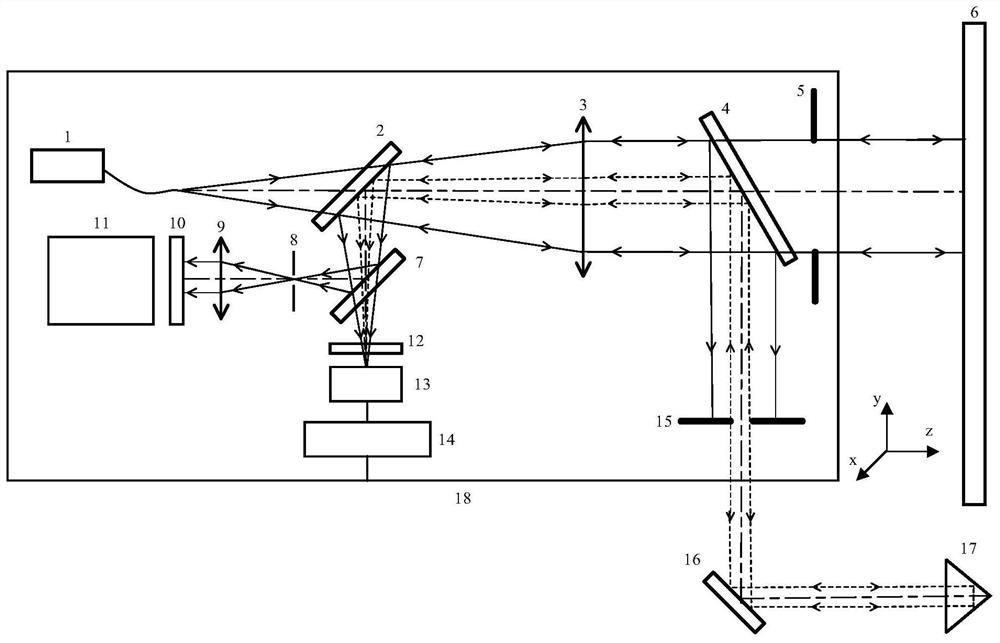

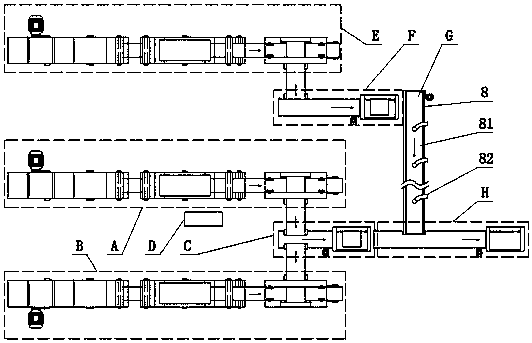

In-situ surface shape splicing measurement device and method for large-aperture planar optical element

ActiveCN112577446AAchieving Stitching MeasurementsAchieve high precision alignmentImage analysisUsing optical meansEyepiecePrism

In order to solve the technical problems that the existing scheme for measuring the surface shape of the large-aperture planar optical element is easily influenced by air flow disturbance and vibration, the measurement dynamic range is small, the surface shape measurement resolution is not high, the scheme cannot be applied to surface shape measurement of various postures in place, and measurementcannot be performed when Power exists in the surface shape of the large-aperture planar optical element, the invention provides an in-situ surface shape splicing measurement device and method for a large-aperture plane optical element. A laser, a semi-transparent semi-reflective mirror, a collimator objective, a diaphragm, a small-hole diaphragm, a collimator eyepiece, a binary optical device, adetector, an attenuation plate, a far-field detector, a drive controller, an electric control diaphragm, a reflector array, a pyramid prism array and a six-degree-of-freedom motion platform are utilized, the dynamic high-precision surface shape splicing measurement of the measured large-aperture planar optical element under various postures is realized, and the measurement precision is not influenced by the external environment.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

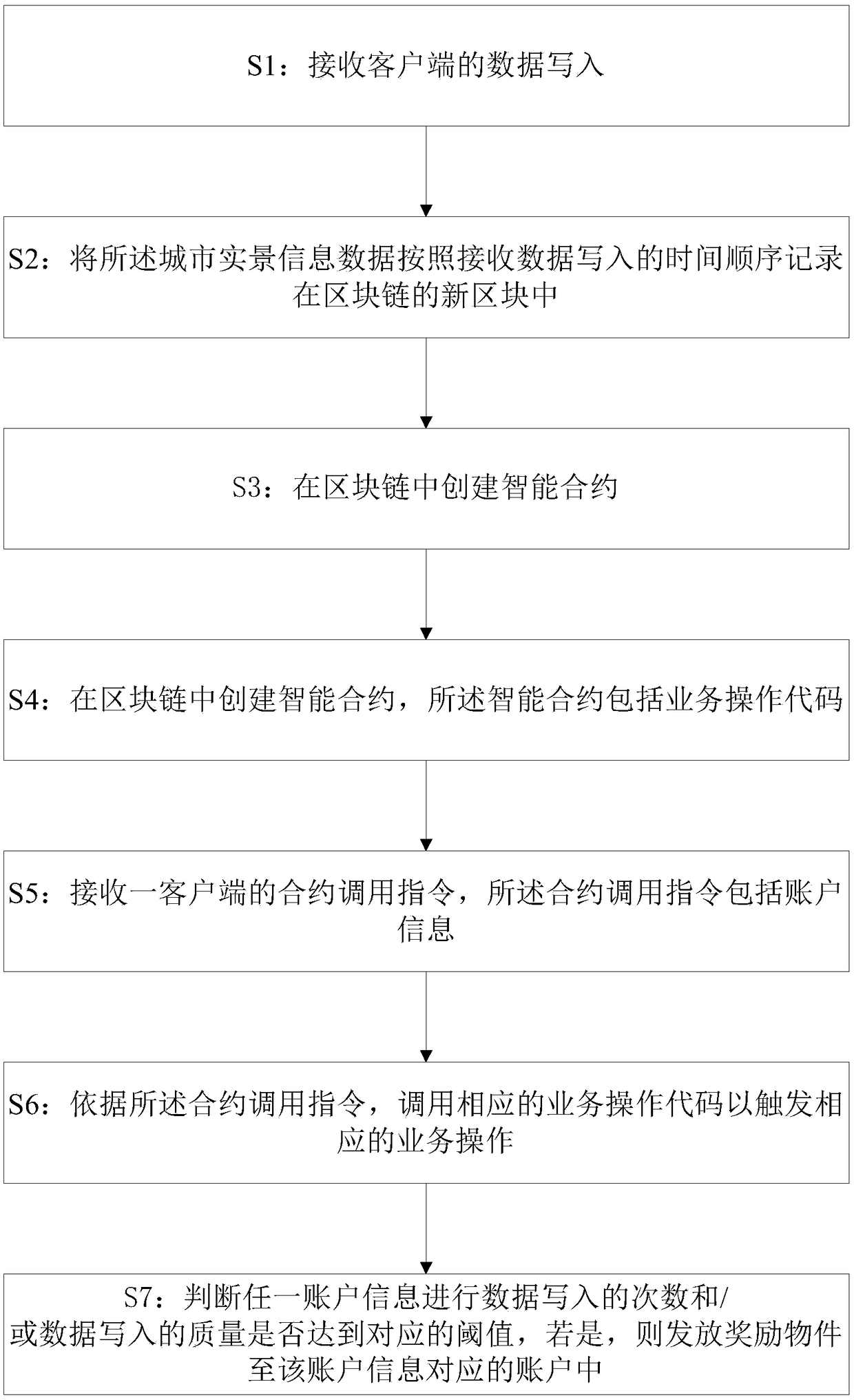

City scene management method based on block chain, electronic device and storage medium

InactiveCN109325368AGuaranteed originalityEnsure safetyData processing applicationsDigital data protectionUser needsParking problem

The invention discloses a city scene management method based on a block chain, an electronic device and a storage medium. The city scene management method comprises the following steps of receiving the data writing of a client end, wherein the data are the city scene information data and the account information; recording the city scene information data in the new block of the block chain according to the time sequence of the received data, and then calling the intelligent contract of the related service according to the user demand, so as to intelligently complete various requirements of theuser. The method of the invention records and preserves the city scene information data according to the time sequence, and the user is not allowed to tamper with and delete the data, thereby ensuringthe originality and safety of the data, saving large amount of cost and reducing a lot of manual links. In addition, the method is very intuitive for the urban management, improves the quality and efficiency of urban management, solves the social public problems, such as the road congestion, the parking problem, etc., from the source, and better meets people 's daily needs of society.

Owner:云量区块链(深圳)有限公司

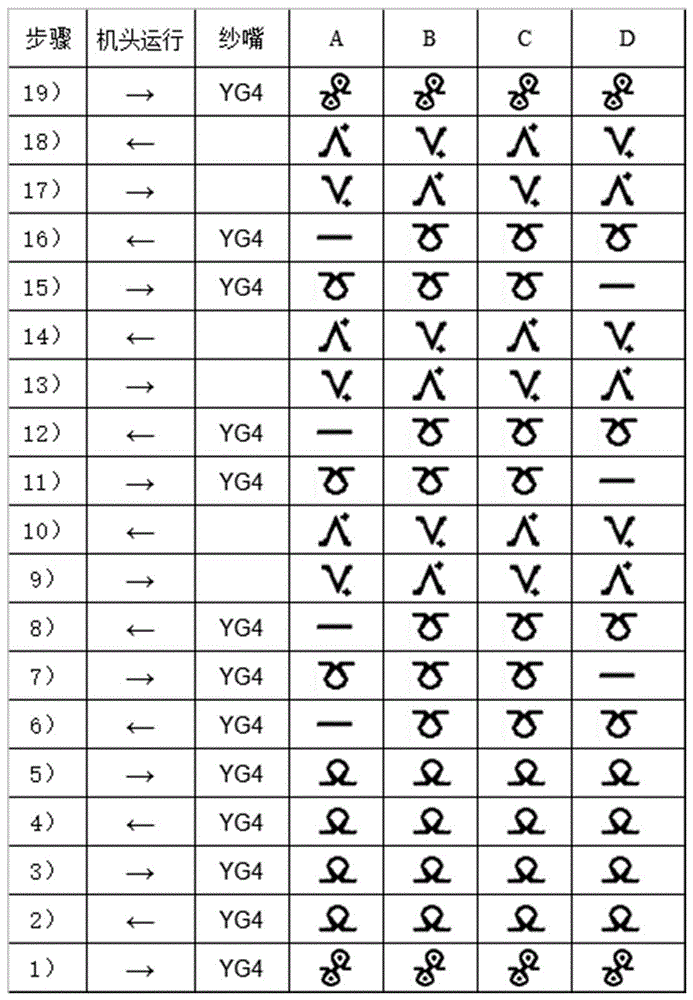

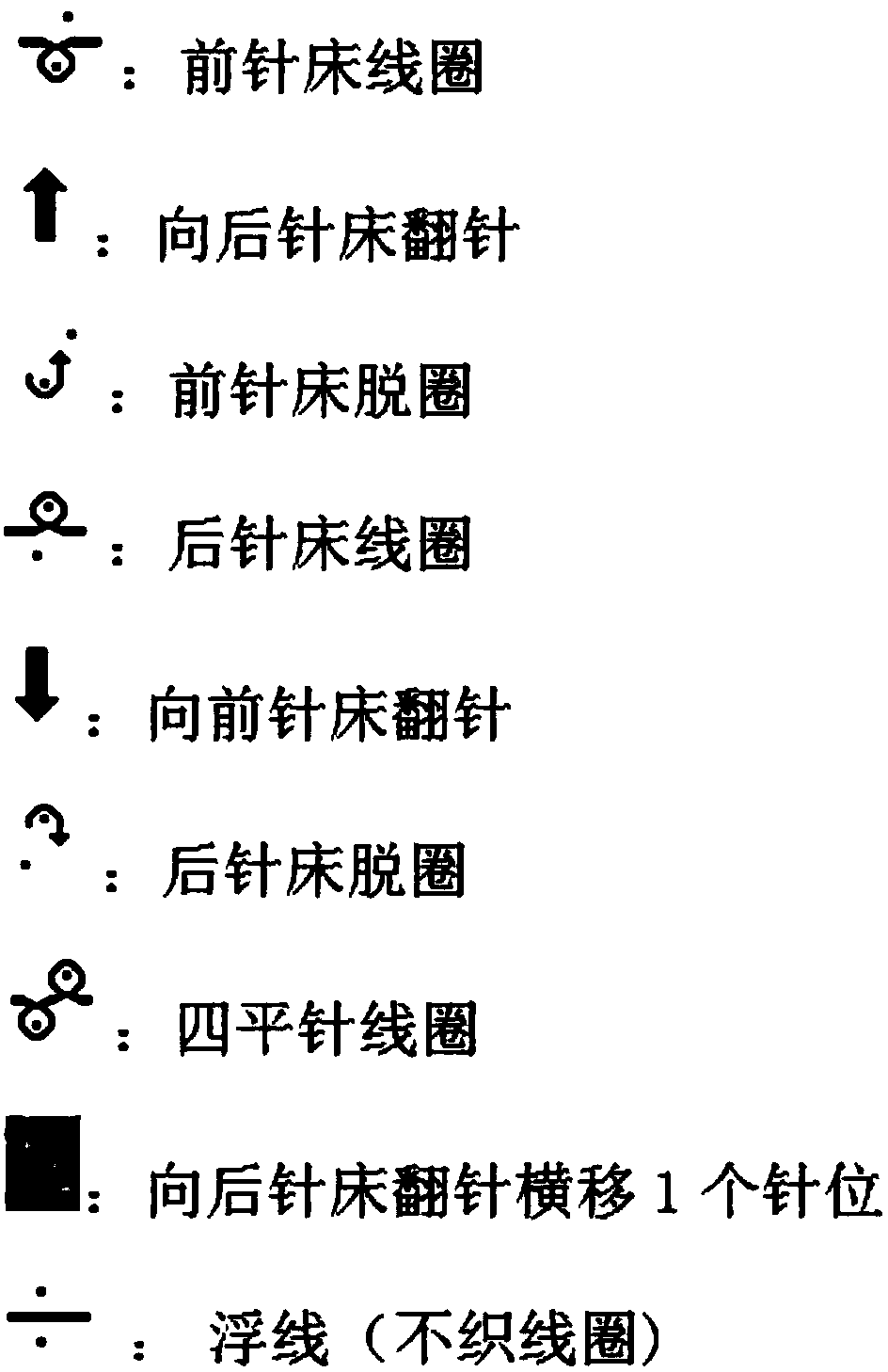

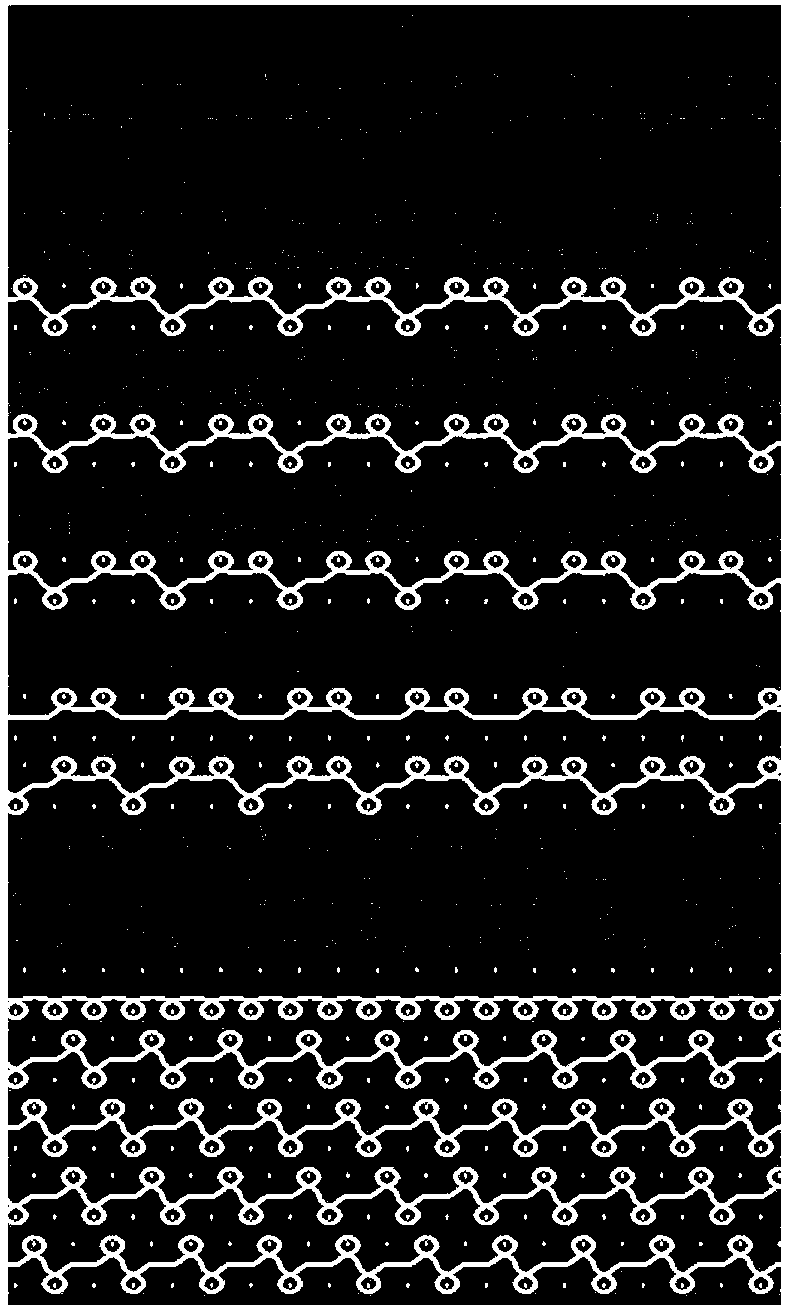

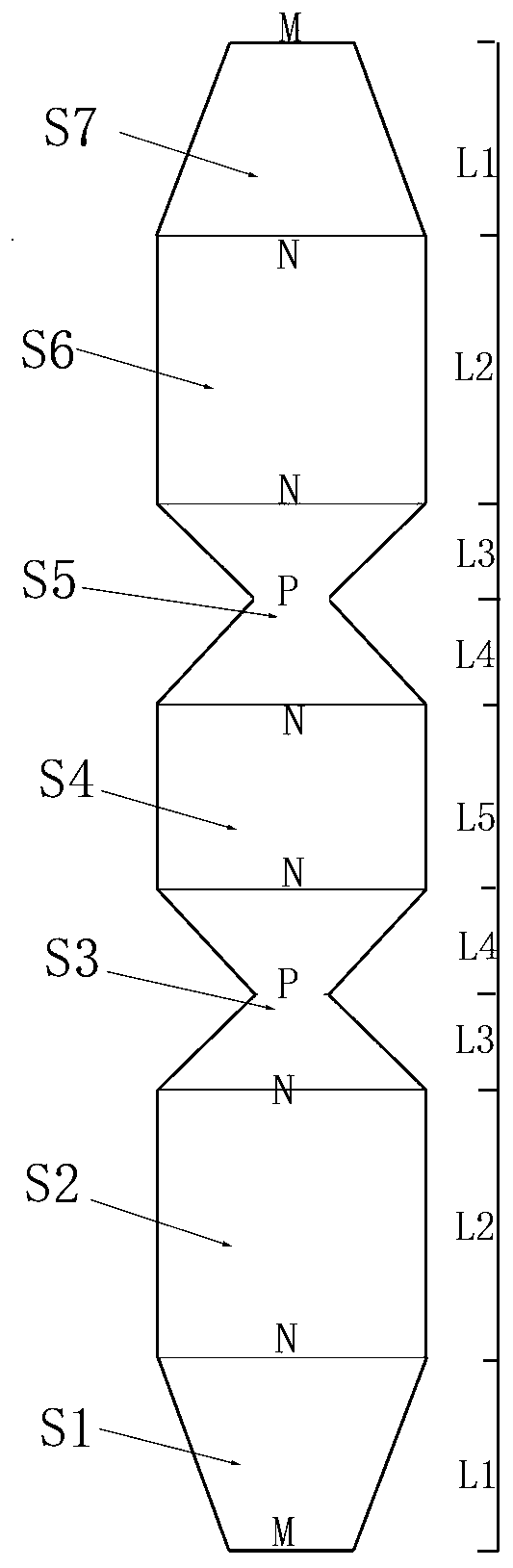

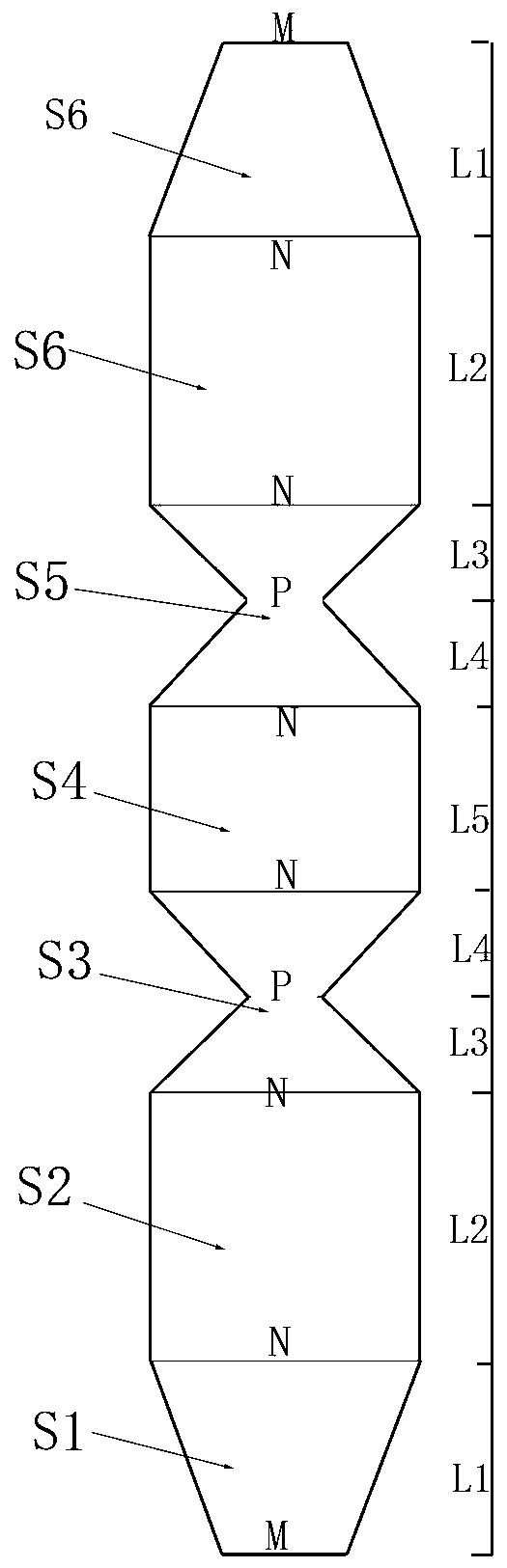

Knitting method of longitudinal shoe eyelet pattern

ActiveCN106637638AImprove weaving is not smoothReduce manual linksWeft knittingShoe lacesEngineering

The invention discloses a knitting method of a longitudinal shoe eyelet pattern. A shoe eyelet is longitudinally formed by adopting partial knitting; top and bottom processing methods of the shoe eyelet adopt four-plain-stitch connection and a shoe lace part penetrates through the shoe eyelet; a plane knitting method adopts front knitting; a needle at a tissue edge has a stealing stitch method and the bottom is knitted by remaining a few of rows, so that a relatively large pore is easy to form; in a knitting process, an empty machine head front and rear needle separation and needle pressing method (a needle withdrawing height is 4 / 1) is applied and a needle pressing method is adopted, so that a phenomenon that the knitting is not smooth after the quantity of partially knitted rows is more is effectively improved; and meanwhile, front knitting and needle pressing movement can be circulated longitudinally and the shoe eyelet is integrally molded and knitted, so that a subsequent manual link is omitted.

Owner:NINGBO CIXING

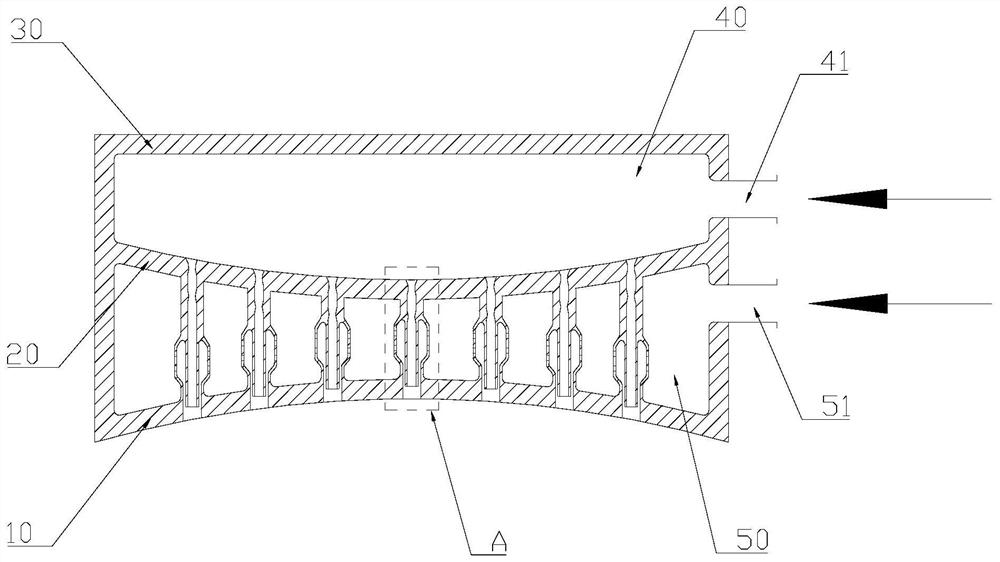

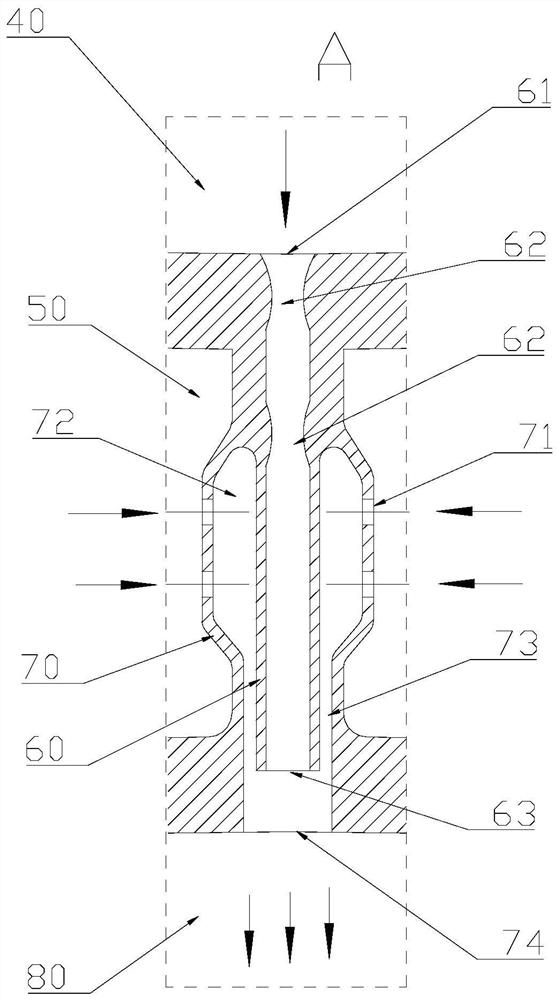

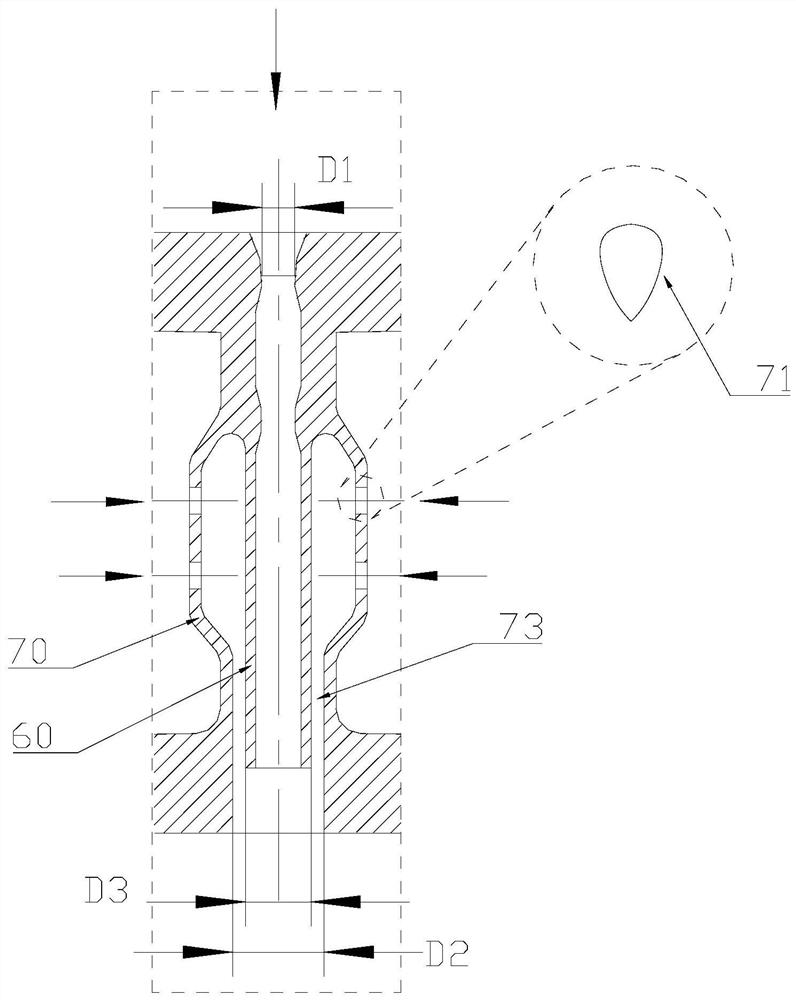

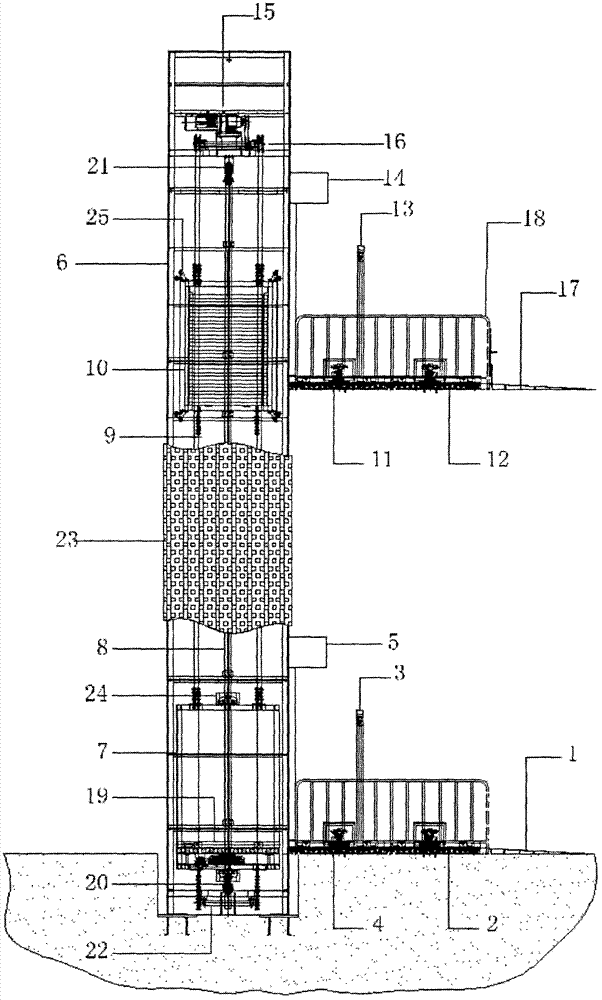

Integrated double-component injector, manufacturing method thereof and space equipment

PendingCN111852691AImprove structural strengthImprove pressure bearing capacityRocket engine plantsInjectorProcess engineering

The invention relates to the technical field of space equipment, in particular to an integrated double-component injector, a manufacturing method thereof and the space equipment. The integrated double-component injector comprises a fuel agent cavity, a first bottom face arranged at the bottom of the fuel agent cavity, a second bottom face arranged on the top of the fuel agent cavity and opposite to the first bottom face and at least one injection unit communicating between the first bottom face and the second bottom face. The first bottom face and the second bottom face are of curved structures. According to the integrated double-component injector, the structural strength of the integrated double-component injector can be improved, the fuel agent cavity has the isostatic pressure flow equalizing characteristic, the flow of each injection unit is more uniformly distributed, and the injection combustion efficiency can be improved.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD +2

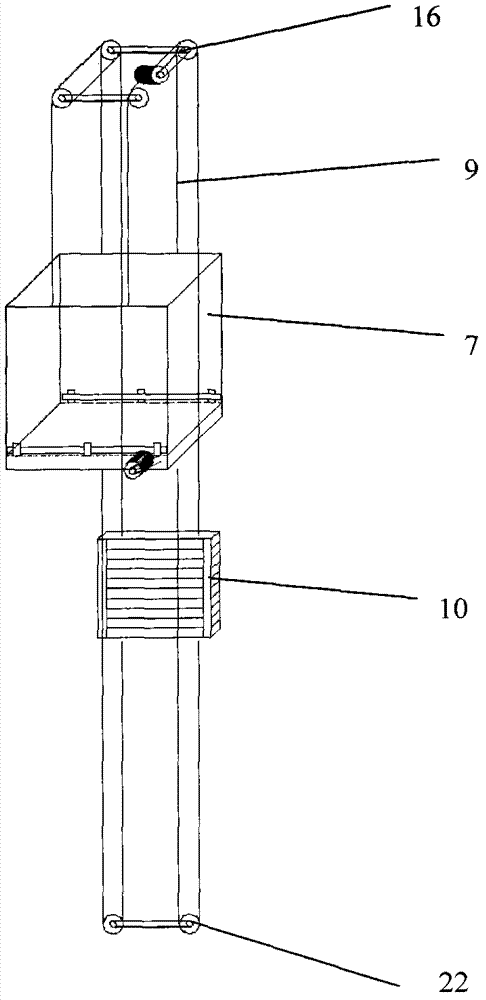

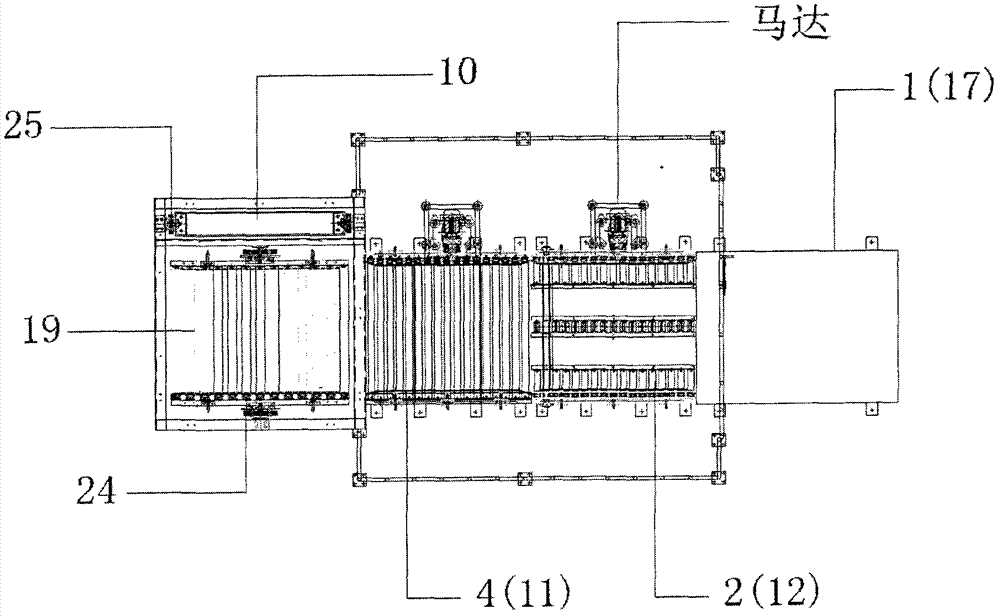

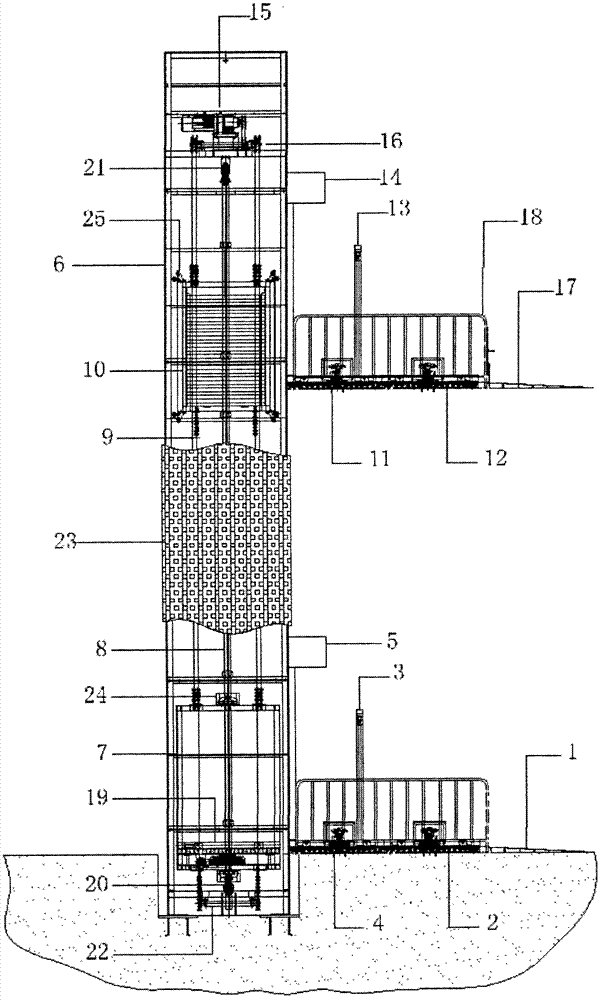

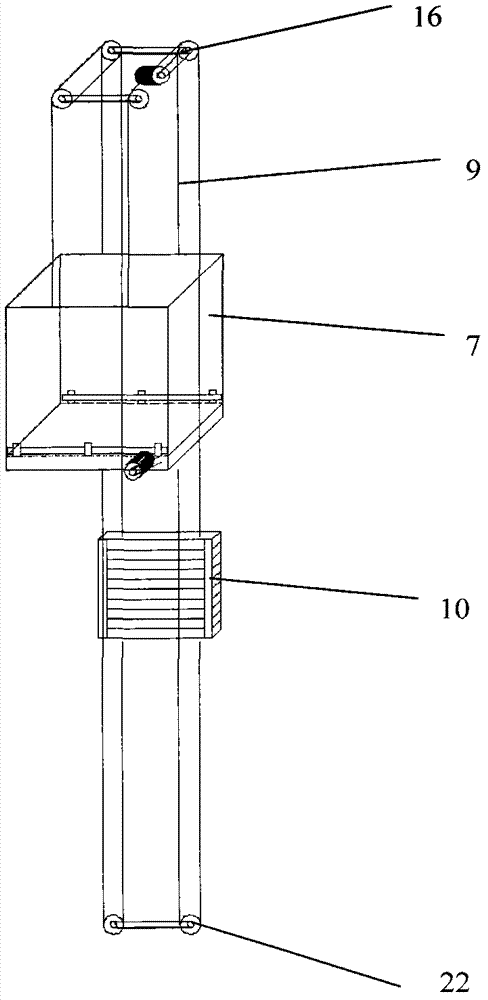

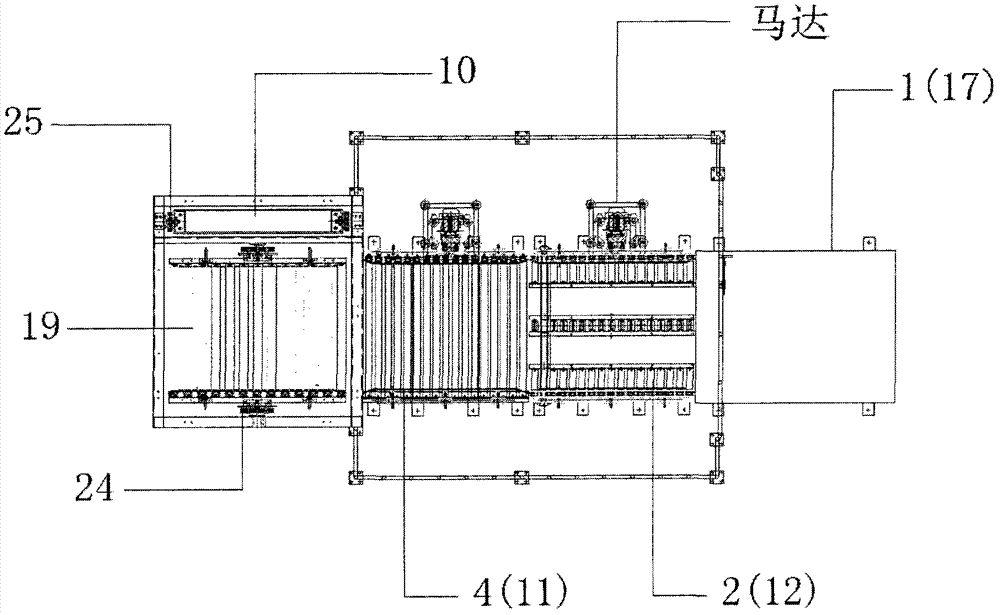

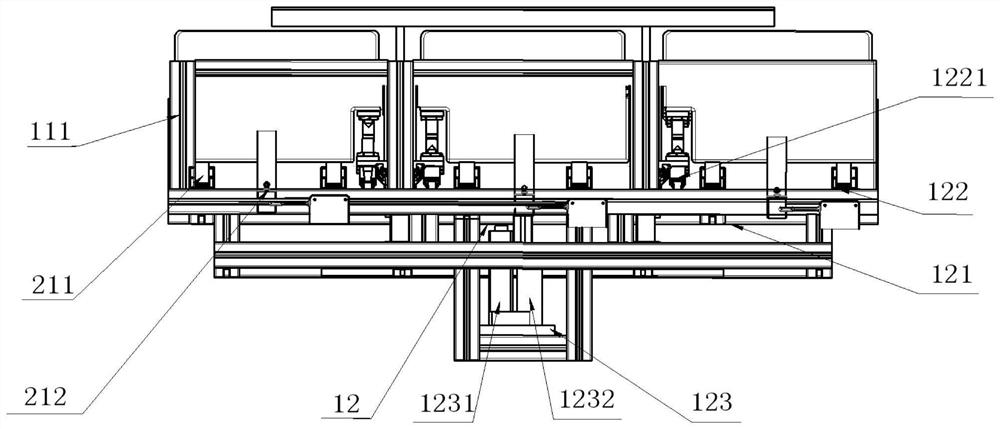

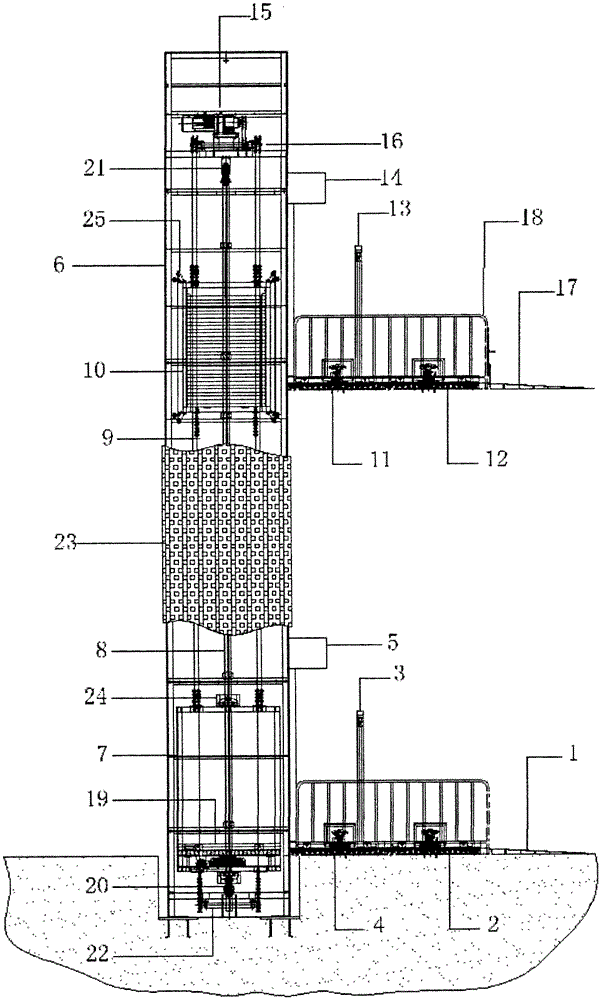

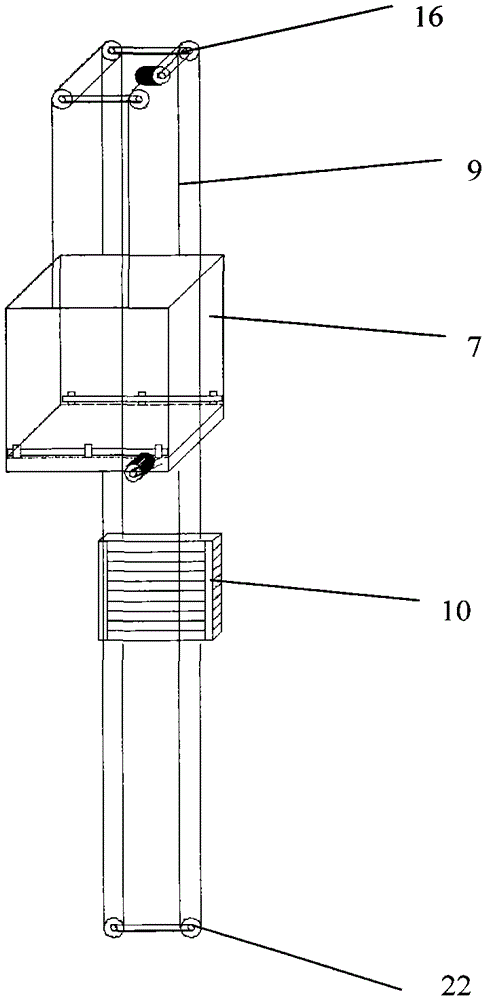

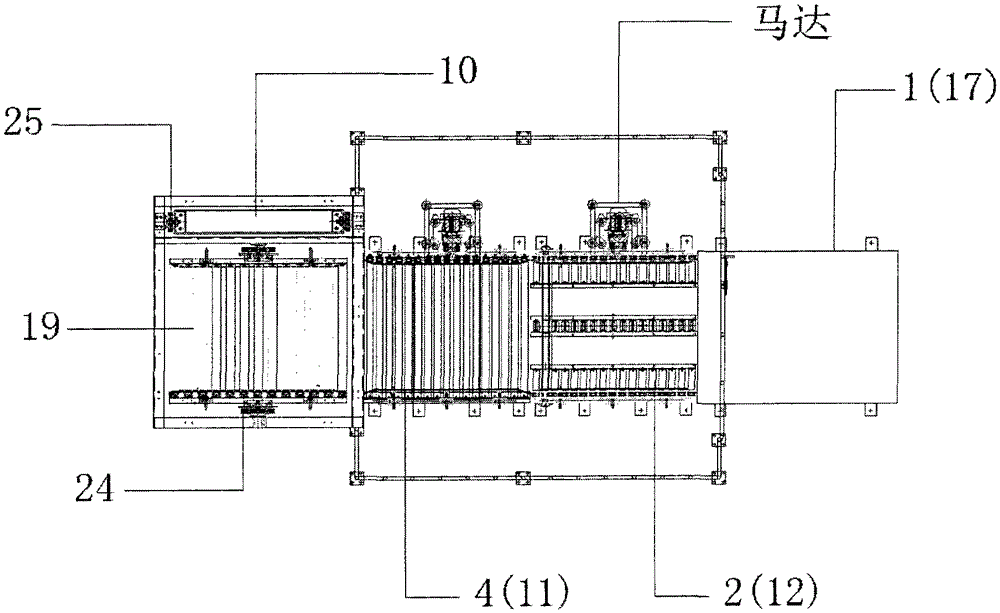

Automatic vertical conveyor

ActiveCN103086135AAutomate managementReduce manual linksBuilding liftsMechanical conveyorsProduction lineEngineering

The invention discloses an automatic vertical conveyor which comprises a vertical conveyor frame, two groups of horizontal conveying rotary drum sections, a vertical conveying cart, a dynamical system, a driving system and two groups of slope boards used for loading and unloading goods. The first group of horizontal conveying rotary drum section is statically connected on the bottom of the vertical conveyor frame through a bolt while the second group of horizontal conveying rotary drum section is statically connected on top of the vertical conveyor frame. The two groups of slope boards used for loading and unloading goods are statically connected with the two groups of horizontal conveying rotary drum sections through bolts respectively. The vertical conveying cart is connected with the dynamical system and the driving system. The vertical rotary drum conveyor can continuously transmit goods vertically, the whole system is controlled by procedures and can be connected with devices of a horizontal conveying line, a production line, a three-dimensional library and the like, so that manual part is saved and the logistics automated management is achieved.

Owner:WUHAN HAILAN LOGISTICS EQUIP

Buttonhole-pattern integrated knitting method for top flies with rib textures

The invention relates to a buttonhole-pattern integrated knitting method for top flies with rib textures. In a first step, a head moves rightward to drive a left No. 2 yarn carrier to knit a pluralityof rows of elastic ribbons, and the elastic ribbons are hooked by a comb of a flat knitting machine; the head moves rightward to drive a left No. 1 yarn carrier to knit a plurality of rows of 1X1 ribworks and a plurality of rows of a single side by using accessory threads; two-stitch loops are transferred to a rear needle bed, and one-stitch loops are transferred to a front needle bed; the head moves leftward to drive a right No. 1 yarn carrier to knit a plurality of rows of two-stitch rear needle bed loops and one-stitch front needle bed loops by using accessory threads; the head moves rightward to drive the left No. 1 yarn carrier to knit a plurality of rows of two-stitch rear needle bed loops and one-stitch floating threads by using accessory threads; rightward traversing is carried out for a stitch, transferring is carried out, and the one-stitch front needle bed loops are transferred backward; the head moves leftward to use the left No. 1 yarn carrier to knit a plurality of rowsof two-stitch rear needle bed loops and one-stitch front needle bed loops by using accessory threads; and the front needle bed is disengaged from one row of loops. The buttonhole-pattern integrated knitting method breaks through an original buttonholing method, buttonholes and a top fly are knitted as a whole, manpower is saved, and the overall appearance of garments is improved.

Owner:SHANDONG SHOW LONG GARMENT

Automatic vertical conveying system

ActiveCN103086154AAutomate managementReduce manual linksCharge manipulationBuilding liftsProduction lineEngineering

The invention discloses an automatic vertical conveying system which comprises: the goods are placed on a first horizontal conveying rotary drum section by a slope plate used for loading and unloading goods, then the goods are transmitted onto a second horizontal conveying rotary drum section and are further transmitted forwards. The goods are transmitted into a vertical conveying trolley through the horizontal conveying rotary drum. The vertical conveying motor of the trolley drives a top chain wheel through a transmission chain and the top chain wheel drives the vertical conveying trolley to lift along a trolley track by using the trolley to lift a chain. The goods are conveyed onto a third horizontal conveying rotary drum section through the horizontal conveying rotary drum section and transmitted forward to a fourth horizontal conveying rotary drum section. The vertical conveying trolley falls back to the second horizontal conveying rotary drum section along the trolley track. The vertical rotary drum conveyor can continuously transmit goods vertically, the whole system is controlled by procedures and can be connected with devices of a horizontal conveying line, a production line, a three-dimensional library and the like, so that manual part is saved and the logistics automated management is achieved.

Owner:WUHAN HAILAN LOGISTICS EQUIP

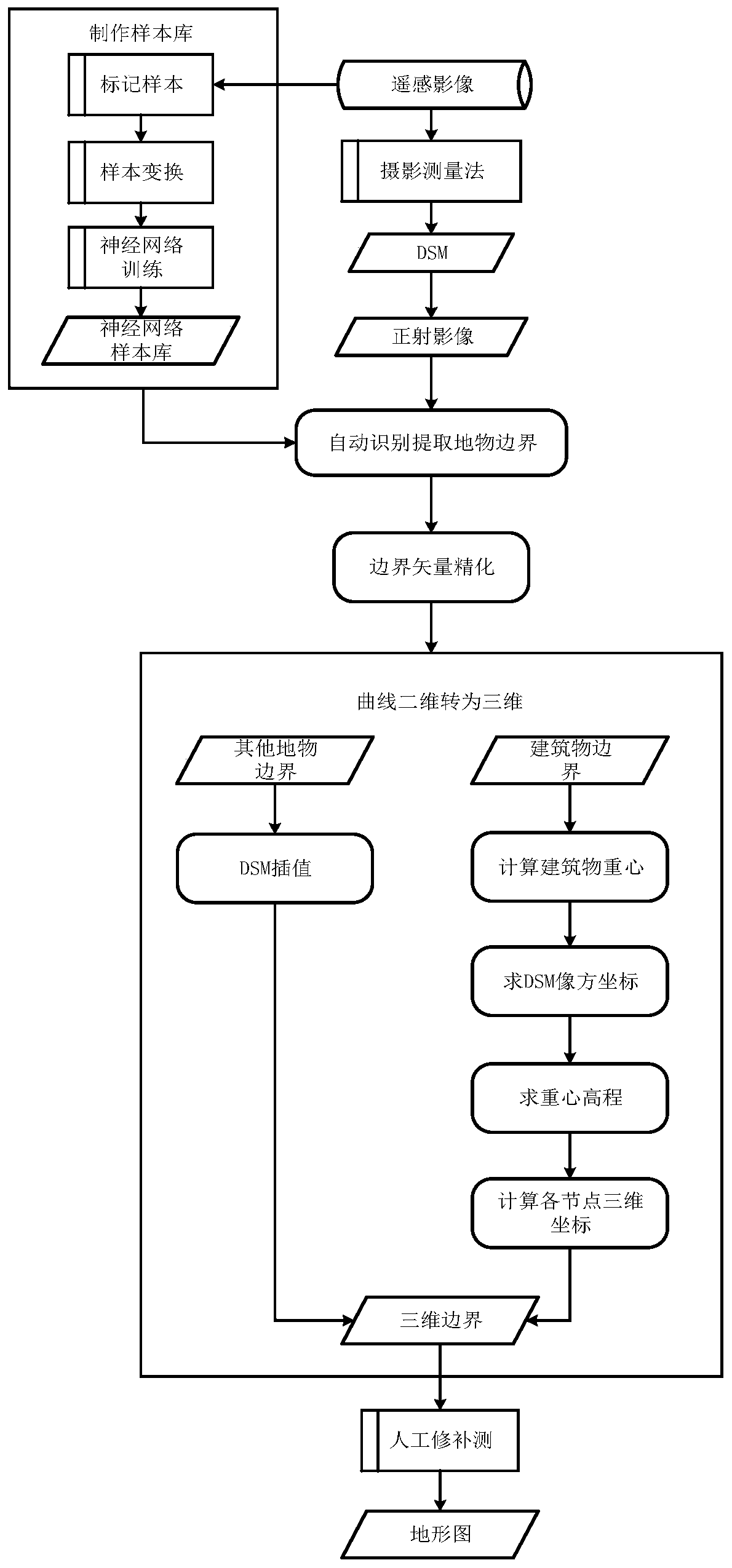

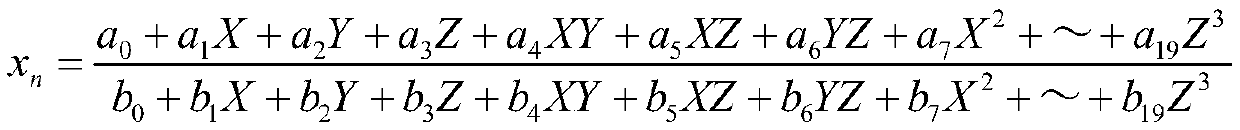

Method for extracting surface feature elements in topographic map

PendingCN111382715AReduce manual linksImprove acquisition efficiencyScene recognitionNeural architecturesComputer graphics (images)Computer vision

The invention discloses a method for extracting surface feature elements in a topographic map, which comprises the following steps of: generating an ortho-image and a DSM (Digital Subscriber Module) based on a remote sensing image; respectively making a sample library of each type of elements; matching different ground objects in the image through the trained neural network sample library of eachtype of element samples to obtain a ground object element planar region, detecting a surface and extracting a ground object boundary vector; matching the buildings on the original image, and matchingthe non-buildings on the orthoimage; refining the ground object boundary vector; converting the refined two-dimensional curve into a three-dimensional curve; converting building boundaries from a two-dimensional curve to a three-dimensional curve by adopting rational polynomial transformation or forward intersection, and non-building boundaries are converted from the two-dimensional curve to the three-dimensional curve by adopting a DSM interpolation algorithm; and processing the three-dimensional curve to obtain a topographic map. Manual links in topographic map production are reduced, and the geographic information data processing efficiency is greatly improved.

Owner:BEIJING GEO VISION TECH

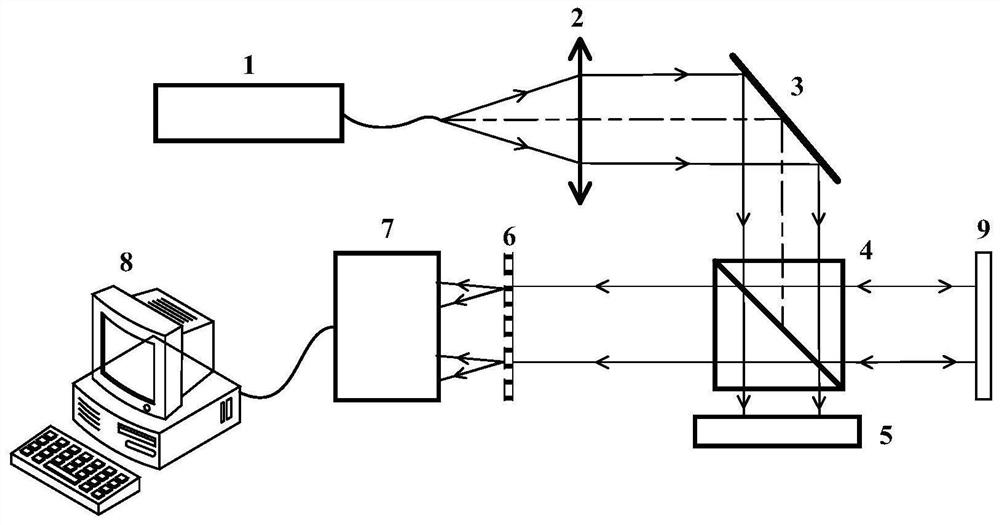

Measuring device and method capable of dynamically measuring surface shape of planar optical element

InactiveCN112504164AAchieve alignmentHigh precision alignmentUsing optical meansPhysicsMeasurement plane

In order to solve the technical problems of low measurement precision, small measurement dynamic range and poor measurement real-time performance of an existing planar optical element surface shape measurement device, the invention provides a measuring device and method capable of dynamically measuring the surface shape of a planar optical element. According to the invention, a laser, a spectroscope, a collimator objective, an attenuation plate, a far-field aiming detector, a small hole, an ocular lens, a binary optical device and a detector are utilized to realize dynamic high-resolution measurement of the surface shape of the measured plane optical element, and the measurement process is not influenced by the external environment; The far-field aiming detector is used for measuring inclination information of the measured planar optical element relative to light beams incident to the surface of the measured planar optical element in real time, so that high-precision alignment is realized, and subsequent high-precision measurement can be realized; and the adopted binary optical device is a micro-lens array or a mixed modulation grating, the corresponding measurement principles arethe Hartmann Shack principle and the transverse shearing interference principle respectively, and compared with a traditional phase shift interference method, the method has a larger measurement dynamic range.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

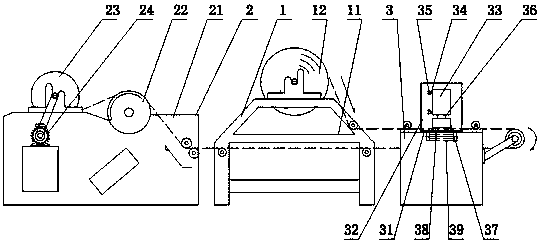

Automatic shaping device for polypropylene hernia-repair mesh

InactiveCN107837127AImprove production environmentHigh degree of automationProsthesisEngineeringPolypropylene

The invention discloses an automatic forming device for a polypropylene hernia patch, which comprises an upper layer mesh forming device, a connector forming device, a lower layer mesh forming device, a first compounding device and a second compounding device. The upper mesh forming device has the same structure as the lower mesh forming device. The upper mesh forming device can cut and shape the mesh from the cloth roll, and the connecting body forming device can cut and shape the connecting body from the cloth roll. The upper mesh and the connecting body are sent to the first forming device, and the operator will connect The body is placed in the composite die, the composite punch is pressed down and the upper mesh and the connecting body are pressed and welded together, the lower mesh forming device cuts out the lower mesh, and sprays on the lower mesh through the drug spraying device For the medicine, the dried lower mesh is compounded for the second time with the first compounded upper mesh and the connecting body. The invention can reduce manual links, reduce labor costs, improve production efficiency, and has good practical value.

Owner:武汉蓝普医品有限公司

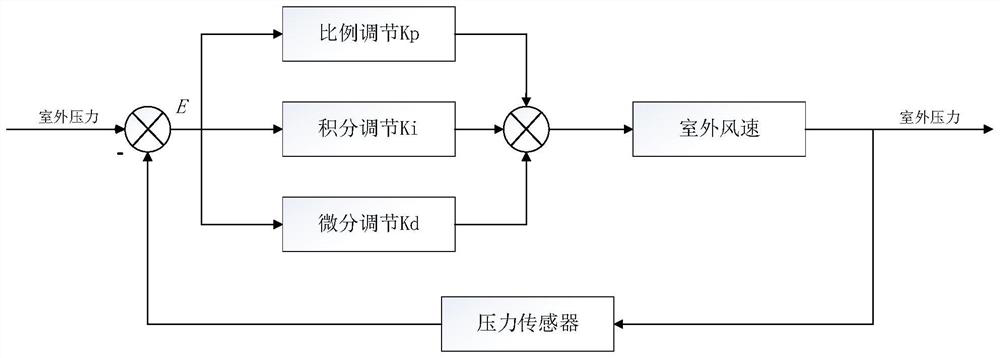

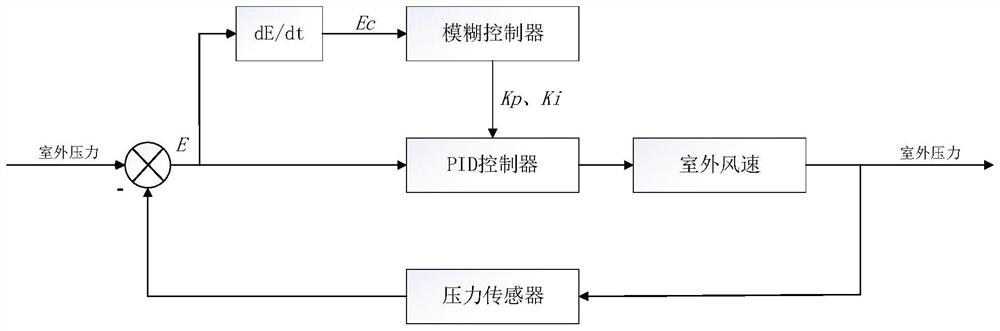

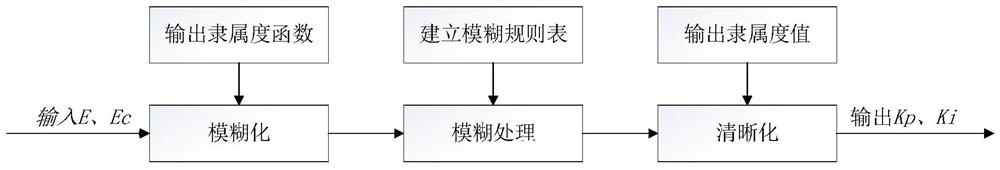

Air conditioner control method and air conditioner

ActiveCN112904709ATime-sensitiveBoth stableControllers with particular characteristicsDefuzzificationControl signal

The invention provides an air conditioner control method. The method comprises the steps of determining a pressure error value and a pressure error change value based on an actual pressure value and a target pressure value; defining a fuzzy subset, establishing a discrete domain, and calculating a pressure error value and a membership degree of a pressure error change value to the fuzzy subset; adaptively generating a fuzzy rule table according to system characteristics and environmental conditions; performing defuzzification according to a gravity center method, and determining a proportion parameter increment and an integral parameter increment; and based on a calculation formula of a PID controller, the proportion parameter increment and the integral parameter increment, obtaining a control signal of an outdoor fan, and then adjusting the speed of the outdoor fan. According to the air conditioner control method, the link of manual trial and error in the process of establishing the fuzzy rule table is omitted, resources and cost are saved, meanwhile, the operation period of the fuzzy rule table is effectively shortened, and the air conditioner operation process is more stable and reliable. The invention further provides the air conditioner adopting the method, and the air conditioner has the advantages of timeliness and stability.

Owner:QINGDAO HISENSE ELECTRONICS EQUIP

Machined round cap

ActiveCN104068551AStable structureQuality improvementHatsHeadwear capsManufactured materialPlastic film

The invention provides a machined round cap. The machined round cap comprises a cap body and a cap opening; the cap body is formed from two pieces of non-woven fabrics or plastic films by virtue of heat sealing; a covered edge is formed at the edge of the cap opening and an elastic band is welded in the covered edge. The machined round cap has the advantages of secure structure, reliable quality, high automation degree, low production cost and the like. Due to the design of the semicircular cap body formed from two pieces of non-woven fabrics or plastic films by virtue of heat sealing, in combination with the automatic production process, the production materials can be greatly saved. The cap body is sheared by use of a special cutting roller after being heat-sealed by use of a heat sealing roller, and the whole process can be carried out through one step and realized automatically. The machined round cap is reasonable in structure and consistent in dimension specification, and thus is convenient for large-scale production by use of a full-automatic machine, and as a result, the manual work links are reduced, the production cost and the waste of the raw materials are reduced and the enterprise competitiveness is enhanced.

Owner:XIANTAO ZHONGTAI PROTECTIVE PROD

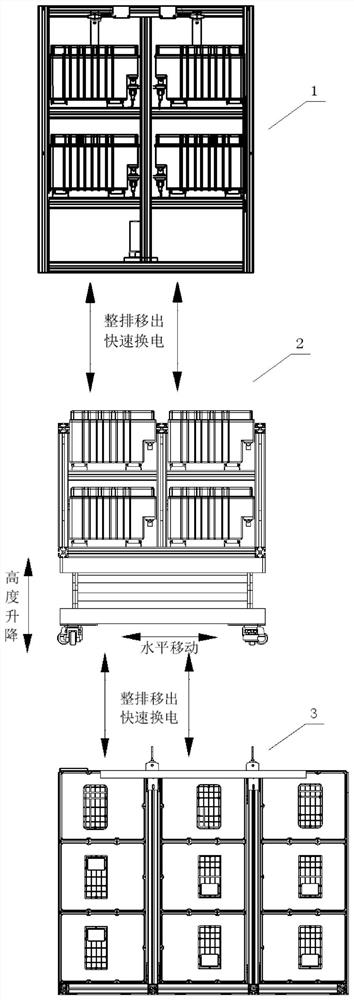

Quick-change system and method for standardized battery modules of electric vehicles

ActiveCN110682894BRealize automatic chargingRealize loading and unloadingCharging stationsElectric propulsion mountingElectrical batteryElectric cars

The invention discloses a quick-change system and method for a standardized battery module of an electric vehicle. The quick-change system includes a charging device and a quick-change transfer device. The battery module on the device is corresponding; the quick-change method charges the battery module after the electrode plate lifting and charging assembly of the charging device rises, and the electrode plate lifting and charging assembly descends after being fully charged, and the battery module is pushed into the quick-change transfer device, the transfer sliding mechanism of the quick-change transfer device transfers the battery module from one end of the carrier to the other end, and the quick-change transfer device is transferred to the installation device of the electric vehicle standardized battery module to automatically install the battery module. Compared with the prior art, the quick-change system of standardized battery modules for electric vehicles provided by the present invention adopts the cooperation of electrode plate lifting and charging components and quick-change transfer devices to realize automatic loading and unloading of battery modules, reducing labor costs. links, save man-hours and reduce costs.

Owner:湖南海博瑞德电智控制技术有限公司

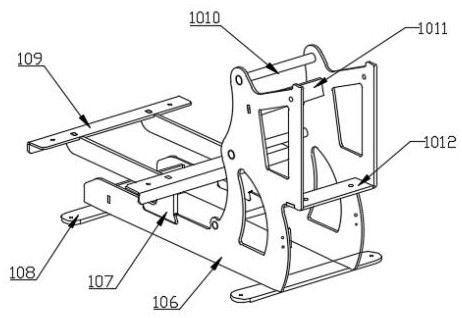

Integrally-welded movable pressure support

InactiveCN112046135AImprove structural strengthAvoid security risksTransfer printingMachinePyrography

The invention relates to the technical field of pyrography machines, and particularly discloses an integrally-welded movable pressure support. The support comprises a rack, wherein a second rotating mechanism and a first rotating mechanism are rotatably connected to the rack, and a connecting mechanism is rotatably connected between the first rotating mechanism and the second rotating mechanism. On the basis of an existing pyrography machine structure, a fastener assembling process is abandoned, robot integrated welding is adopted to replace manual assembling, manual links are reduced, and thereject ratio of products is reduced; and by use of integrated welding, the structural strength of a whole machine is greatly improved, a safety risk brought to a user by structure loosening of an original pyrography machine due to high-frequency use is avoided, the rigidity of the whole machine is greatly improved, and the production process is simplified.

Owner:义乌泰乐机械设备有限公司

A kind of knitting method of sleeve type fully formed seamless knitted shoes

The invention discloses a sleeve type fully-formed seamless knitted shoe knitting method. A whole shoe is knitted by means of sleeve type knitting, the shoe is knitted from a shoe head to a shoe throat portion at first, then reverse knitting is performed for knitting a lining shoe head, and finally two layers are achieved by combination. The sleeve type knitting method breaks a traditional tailing and sewing process, and time and subsequent manual processes are saved due to direct forming.

Owner:NINGBO CIXING

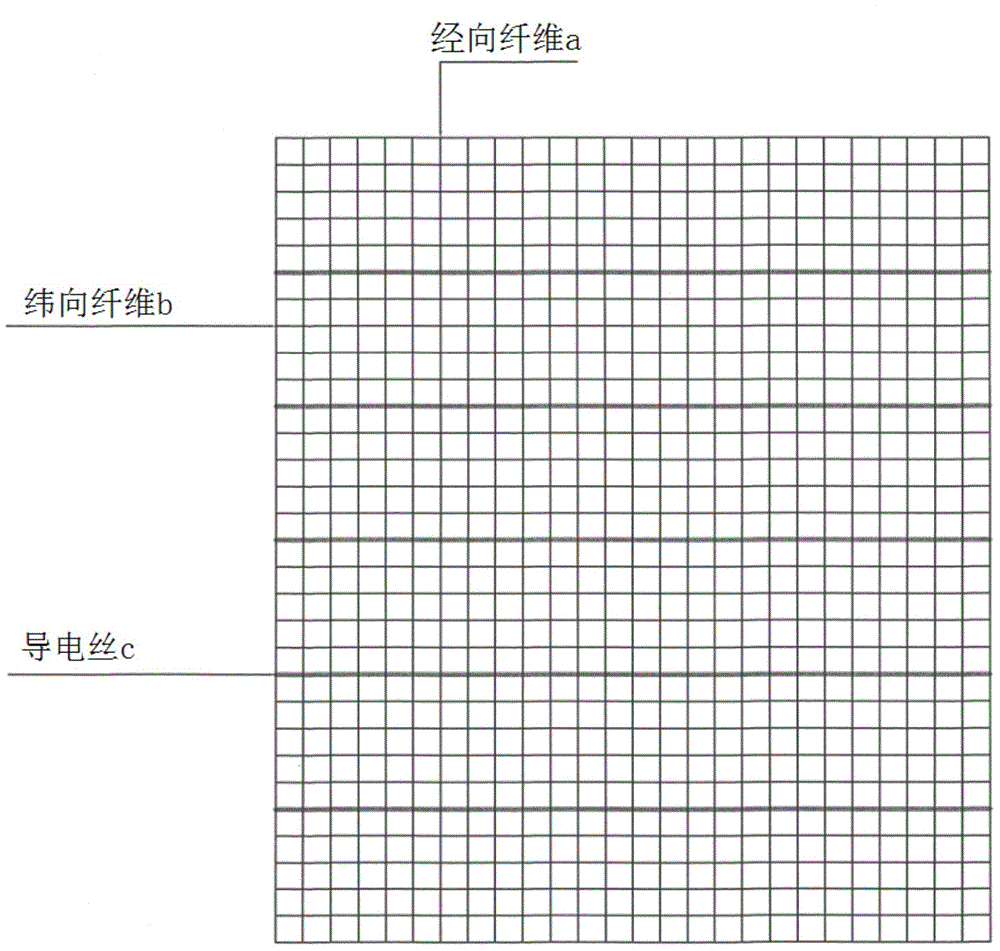

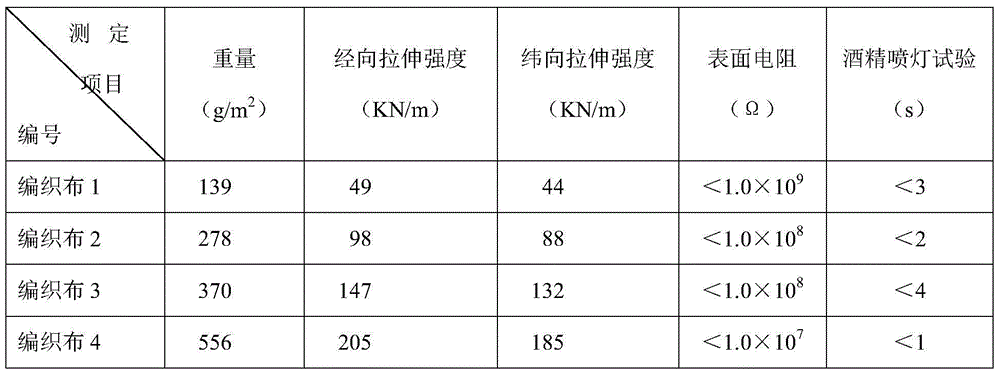

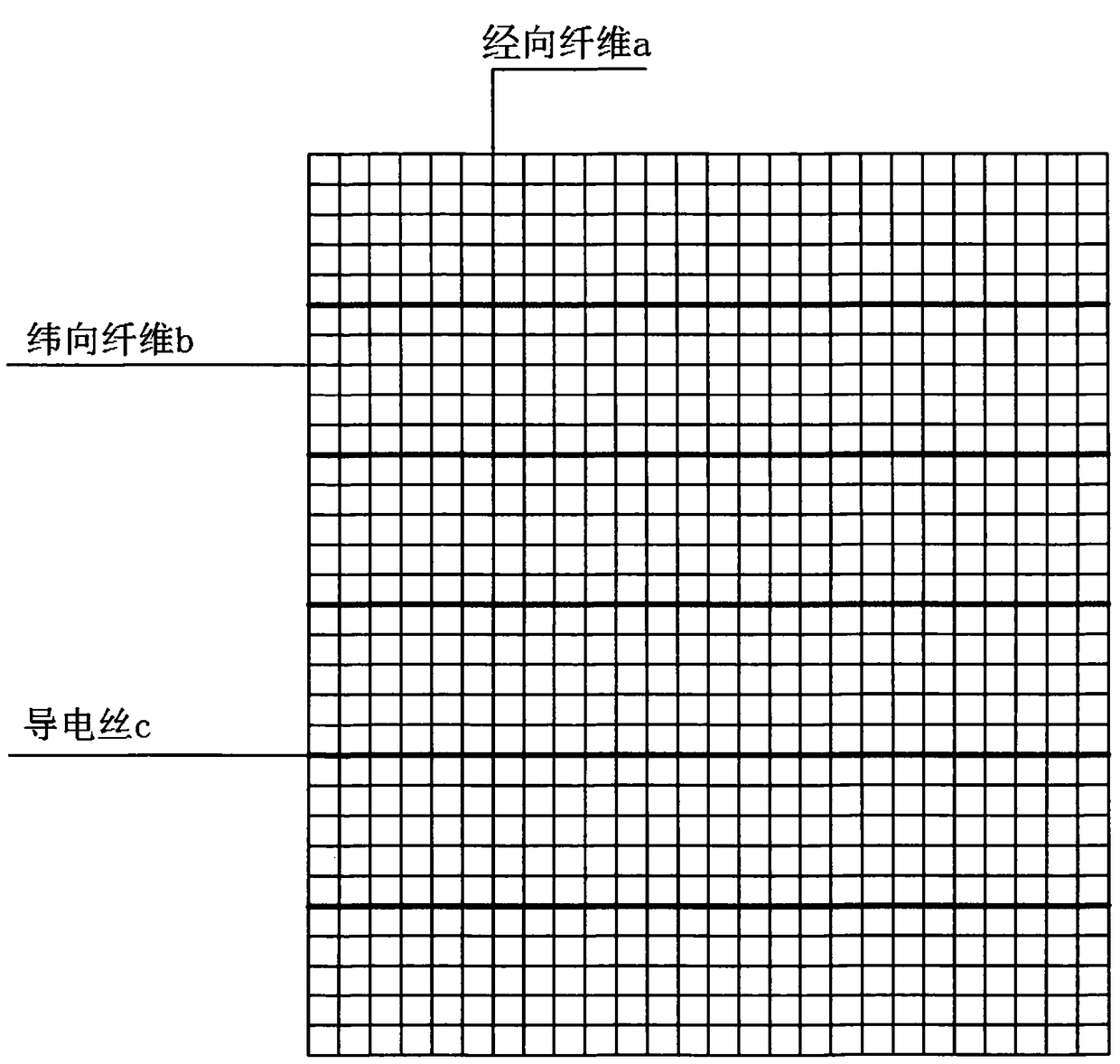

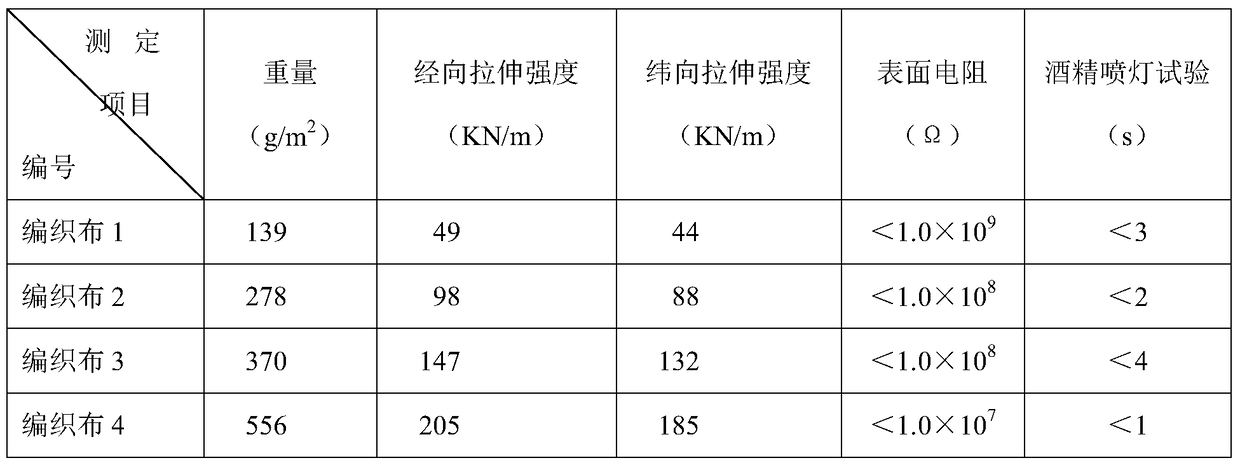

Coal mine underground halogen-free flame-retardant antistatic fiber woven cloth and preparing method of fiber woven cloth

ActiveCN104912577AFlame retardant and antistaticHalogen-free, low toxicity and environmental protectionMaterial fill-upBraidYarnFiber

The invention relates to the technical field of a macromolecular material, in particular to fiber woven cloth and a preparing method of the fiber woven cloth. Coal mine underground halogen-free flame-retardant antistatic fiber woven cloth comprises a fiber woven cloth body, wherein when the fiber woven cloth body is woven by using halogen-free flame-retardant fiber industrial yarns with the fiber number range being 222 dtex to 5555 dtex, a conducting yarn is uniformly embedded and woven into a warp direction and / or a weft direction at equal intervals; and the yarns are directly woven into the halogen-free flame-retardant antistatic fiber woven cloth through a loom. The halogen-free flame-retardant fiber industrial yarns are made of halogen-free flame-retardant polymer slices with the phosphorus content being 5000 ppm to 8500 ppm. The fiber woven cloth and the preparing method have the obvious advantages that on the premise of ensuring the safety performance and the use performance, non-pollution discharge is achieved in the production process; artificial links are few in the production process; the automation degree is high; a product achieves halogen-free low-toxicity and environment-friendly effects; the weight is light; the installation is fast, convenient and efficient; and the use range is wide, and the like.

Owner:上海鑫荻良实业发展有限公司

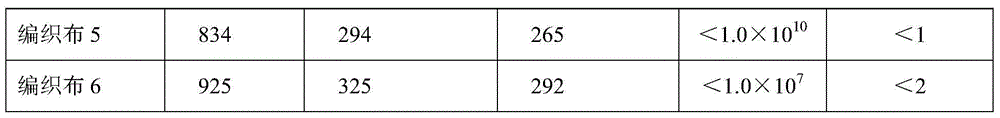

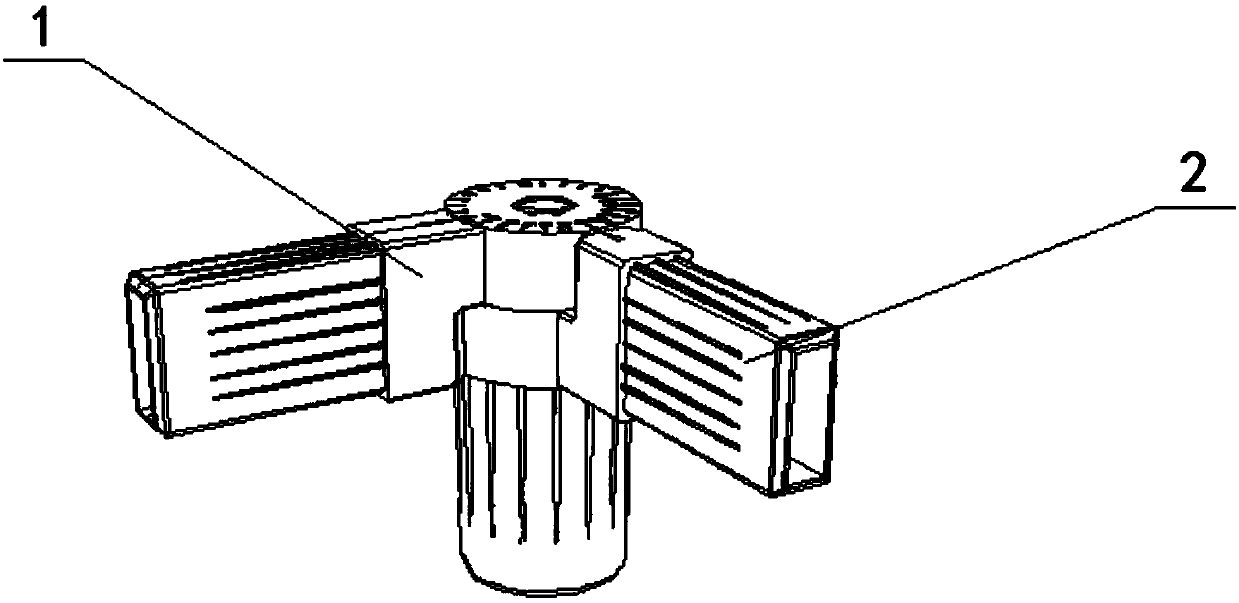

Adjustable type table frame connecting piece, table frame and table

InactiveCN107859675ADoes not take up shipping spaceReduce shipping costsRod connectionsTablesArchitectural engineeringTransportation cost

The invention discloses an adjustable type table frame connecting piece. The table frame connecting piece comprises a first connecting assembly and a second connecting assembly; the first connecting assembly is composed of a first connecting seat and a first connecting beam, the first connecting seat is a cylindrical mounting seat, and the first connecting beam is a hollow pipe body and is fixed on the side surface of the first connecting seat; and the second connecting assembly is composed of a second connecting seat, a second connecting beam and a supporting column connecting pipe, the second connecting beam is fixed on the side surface of the second connecting seat, and the supporting column connecting pipe is a hollow pipe body and is fixed at the bottom of the second connecting seat.The table frame connecting piece can be directly conveyed to a field after being manufactured in a factory to be assembled with cross beams and supporting columns on site, the transportation space canbe not occupied, and the transportation cost can be saved; and in the assembling process, the connecting piece is directly inserted and connected, so that the welding time is saved, and the cost is further saved.

Owner:南京大德科教设备有限公司

An automatic vertical conveying method

ActiveCN103086154BAutomate managementReduce manual linksCharge manipulationBuilding liftsProduction lineWheel drive

The invention discloses an automatic vertical conveying system which comprises: the goods are placed on a first horizontal conveying rotary drum section by a slope plate used for loading and unloading goods, then the goods are transmitted onto a second horizontal conveying rotary drum section and are further transmitted forwards. The goods are transmitted into a vertical conveying trolley through the horizontal conveying rotary drum. The vertical conveying motor of the trolley drives a top chain wheel through a transmission chain and the top chain wheel drives the vertical conveying trolley to lift along a trolley track by using the trolley to lift a chain. The goods are conveyed onto a third horizontal conveying rotary drum section through the horizontal conveying rotary drum section and transmitted forward to a fourth horizontal conveying rotary drum section. The vertical conveying trolley falls back to the second horizontal conveying rotary drum section along the trolley track. The vertical rotary drum conveyor can continuously transmit goods vertically, the whole system is controlled by procedures and can be connected with devices of a horizontal conveying line, a production line, a three-dimensional library and the like, so that manual part is saved and the logistics automated management is achieved.

Owner:WUHAN HAILAN LOGISTICS EQUIP

Halogen-free flame-retardant antistatic fiber woven cloth for coal mine underground and preparation method thereof

ActiveCN104912577BWith permanent flame retardant antistaticExtended service lifeMaterial fill-upBraidFiberYarn

The invention relates to the technical field of a macromolecular material, in particular to fiber woven cloth and a preparing method of the fiber woven cloth. Coal mine underground halogen-free flame-retardant antistatic fiber woven cloth comprises a fiber woven cloth body, wherein when the fiber woven cloth body is woven by using halogen-free flame-retardant fiber industrial yarns with the fiber number range being 222 dtex to 5555 dtex, a conducting yarn is uniformly embedded and woven into a warp direction and / or a weft direction at equal intervals; and the yarns are directly woven into the halogen-free flame-retardant antistatic fiber woven cloth through a loom. The halogen-free flame-retardant fiber industrial yarns are made of halogen-free flame-retardant polymer slices with the phosphorus content being 5000 ppm to 8500 ppm. The fiber woven cloth and the preparing method have the obvious advantages that on the premise of ensuring the safety performance and the use performance, non-pollution discharge is achieved in the production process; artificial links are few in the production process; the automation degree is high; a product achieves halogen-free low-toxicity and environment-friendly effects; the weight is light; the installation is fast, convenient and efficient; and the use range is wide, and the like.

Owner:上海鑫荻良实业发展有限公司

Device and method for in-plane shape splicing measurement of large-aperture planar optical elements

ActiveCN112577446BAchieving Stitching MeasurementsAchieve high precision alignmentImage analysisUsing optical meansEyepieceImage resolution

In order to solve the problem that the existing solutions for measuring the surface shape of large-diameter planar optical components are easily affected by air flow disturbance and vibration, the measurement dynamic range is small, the surface shape measurement resolution is not high, and it cannot be applied to in-situ surface shape measurement of various attitudes. And the technical problem that cannot be measured when there is Power in the surface shape of the large-diameter plane optical element, the present invention proposes a large-diameter plane optical element in-position surface shape splicing measurement device and method, using lasers, half mirrors, Straight objective lens, diaphragm, pinhole diaphragm, collimating eyepiece, binary optics, detector, attenuation plate, far-field detector, drive controller, electronic diaphragm, mirror array, corner prism array, six The degree of freedom motion platform realizes the dynamic and high-precision surface splicing measurement of the measured large-diameter flat optical components in various postures, and the measurement accuracy is not affected by the external environment.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Stabilizer bar conveying and clamping device

PendingCN109365662AAvoid damageExtended service lifeMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses a stabilizer bar conveying and clamping device. The stabilizer bar conveying and clamping device comprises a conveying base (1), and a conveying device is arranged on the conveying base (1). The stabilizer bar conveying and clamping device is characterized in that an aligning device and a clamping device are arranged at the head end and the tail end of the conveying devicerespectively. According to the stabilizer bar conveying and clamping device, manual operation can be reduced, the machining efficiency is improved, and meanwhile, the accident that worker is scalded by a high-temperature stabilizer bar during manual operation is also avoided.

Owner:贵州长江汽车有限公司

A metal bar conveying device and its application method

ActiveCN101786545BReduce manual linksAutomated process extensionControl devices for conveyorsCharge manipulationEngineeringAlloy

A metal bar conveying device and an application method thereof belong to the technical field of alloy production raw material conveying machinery. The structure of the device includes an electric control part, a fixed guide rail, a moving mechanism and a blocking mechanism; the application method of the device is to enable the equipment to control the speed of the first row of materials, and to make the second row and the entire material stack intermittently move. Function. The utility model has the advantages: through the device, the material transfer and automatic feeding are organically combined, the manual link in the middle is omitted, the automatic process is extended, and at the same time, it can be extended to other industries that need automatic delivery of bar materials, especially It is suitable for materials with a ratio of bar length to diameter less than 2.

Owner:SHENYANG NEU-SANKEN IND FURNACE MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com