Machined round cap

A round cap and mechanism technology, applied in hats, hat products, clothing and other directions, can solve the problems of low production efficiency, large waste of materials, poor product uniformity, etc., and achieve the effects of low production cost, solid structure and reliable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

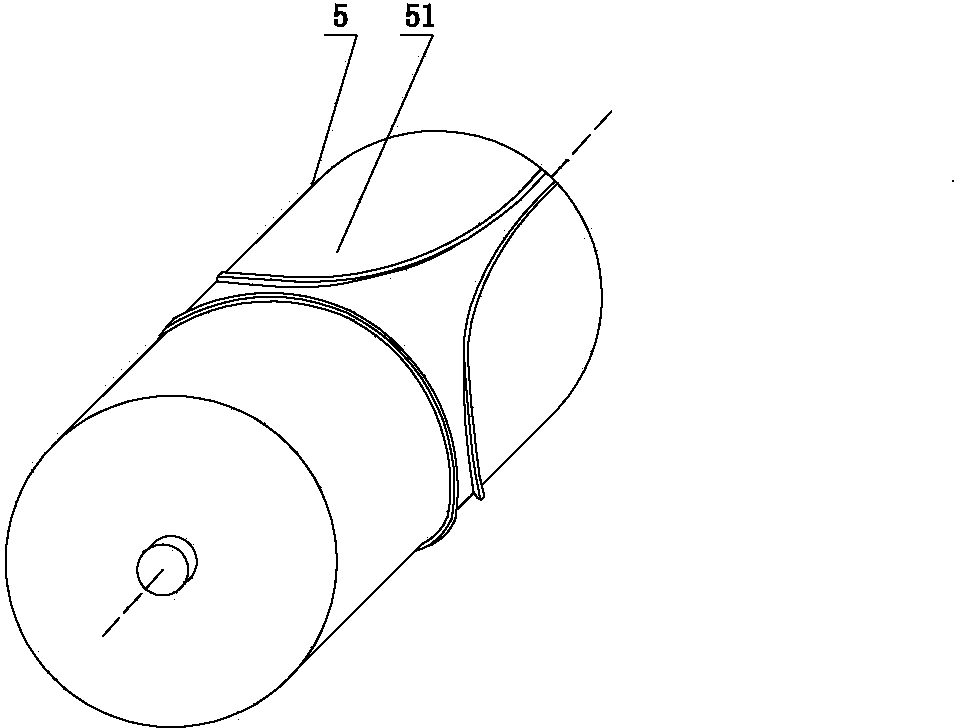

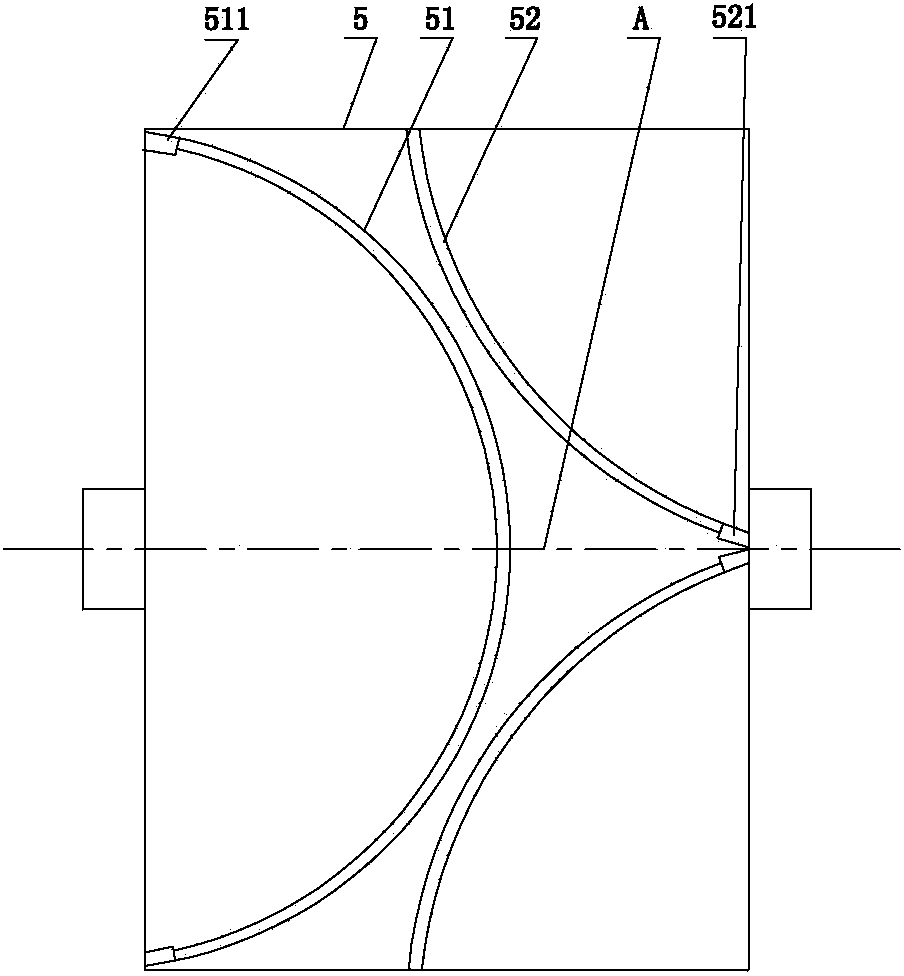

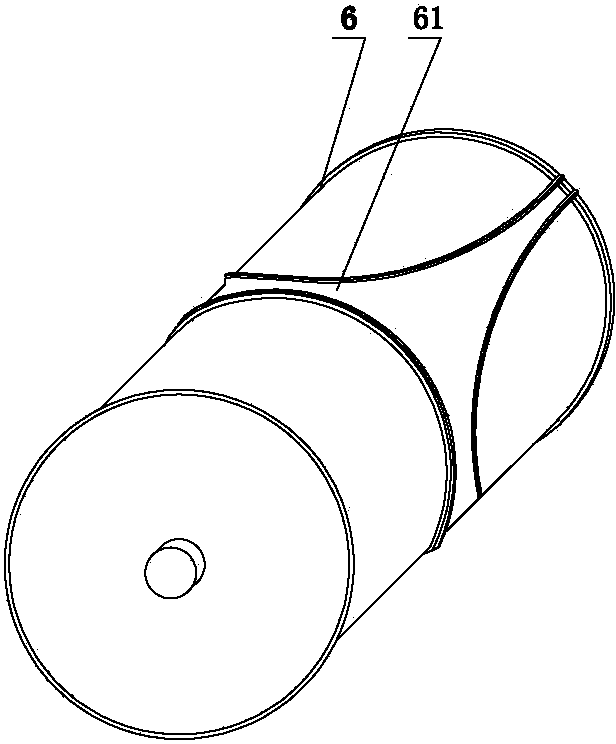

[0024] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. figure 1 It is a schematic diagram of the structure of the non-woven machine-made round cap, figure 2 is a schematic diagram of the structure of the heat-sealing roller, image 3 is the expanded view of the heat-sealing roller, Figure 4 is the structural schematic diagram of the cutting roller, Figure 5 is the expanded view of the cutting roll, Figure 6 It is a schematic diagram of the working state of the heat-sealing roller and the cutting roller.

[0025] As can be seen from the figure, the round cap 123 of this mechanism includes a cap body 1 and a cap mouth 2. The cap body 1 is formed by heat-bonding two pieces of non-woven fabrics or plastic films. The ends are welded together. An elastic band 4 is welded in the wrapping 3, and the width of the wrapping 3 is preferably 4-15mm. The heat-sealed e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com