Gas circuit control system and method for argon arc welding machine

An argon arc welding machine and gas circuit control technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of large volume of external devices, loss of argon gas, unfavorable movement, etc., to improve the level of intelligence, improve Argon utilization rate, the effect of reducing operational complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

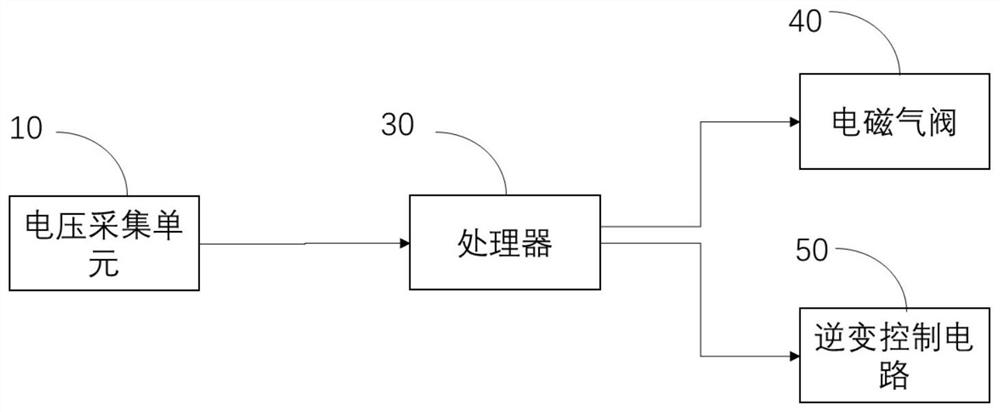

[0061] see figure 1 , the present embodiment provides an argon arc welding machine gas circuit control system, including a voltage acquisition unit 10, a processor 30, an electromagnetic gas valve 40 and an inverter control circuit 50, the processor 30 is connected to the voltage acquisition unit respectively 10. The electromagnetic valve 40 is connected to the inverter control circuit 50, wherein:

[0062] The voltage collection unit 10 collects the voltage of the argon arc welding machine, performs real-time data processing on the voltage, and transmits it to the processor 30;

[0063] The processor 30 controls the electromagnetic gas valve 40 and the inverter control circuit 50 according to the voltage, specifically, the processor 30 outputs to the electromagnetic gas valve 40 and the inverter control circuit 50 control signal to control the electromagnetic valve 40 and the inverter control circuit 50;

[0064] The electromagnetic gas valve 40 controls the on-off of the g...

Embodiment 2

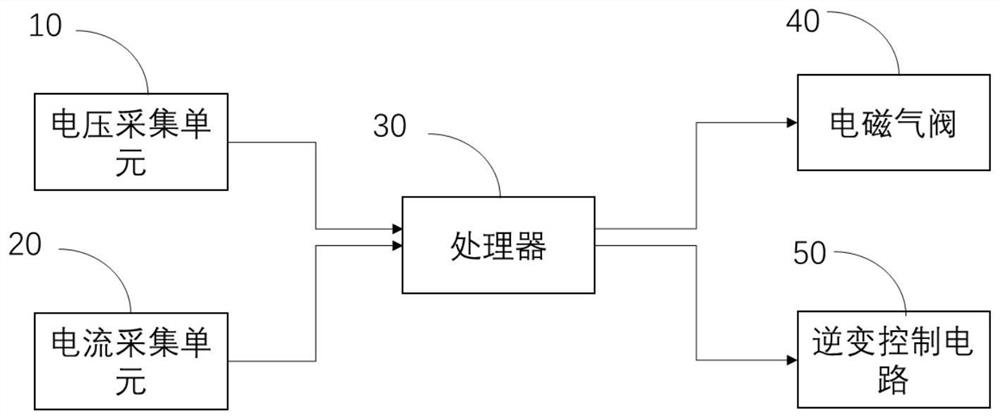

[0075] see figure 2 , the present embodiment provides another argon arc welding machine gas circuit control system, including a voltage acquisition unit 10, a current acquisition unit 20, a processor 30, an electromagnetic gas valve 40 and an inverter control circuit 50, and the processor 30 is respectively It is connected with the voltage acquisition unit 10, the current acquisition unit 20, the electromagnetic valve 40, and the inverter control circuit 50, wherein:

[0076] The voltage collection unit 10 collects the voltage of the argon arc welding machine, performs real-time data processing on the voltage, and transmits it to the processor 30;

[0077] The current collection unit 20 collects the current of the argon arc welding machine, performs real-time data processing on the current and transmits it to the processor 30;

[0078] The processor 30 controls the electromagnetic valve 40 and the inverter control circuit 50 according to the voltage and the current, specific...

Embodiment 3

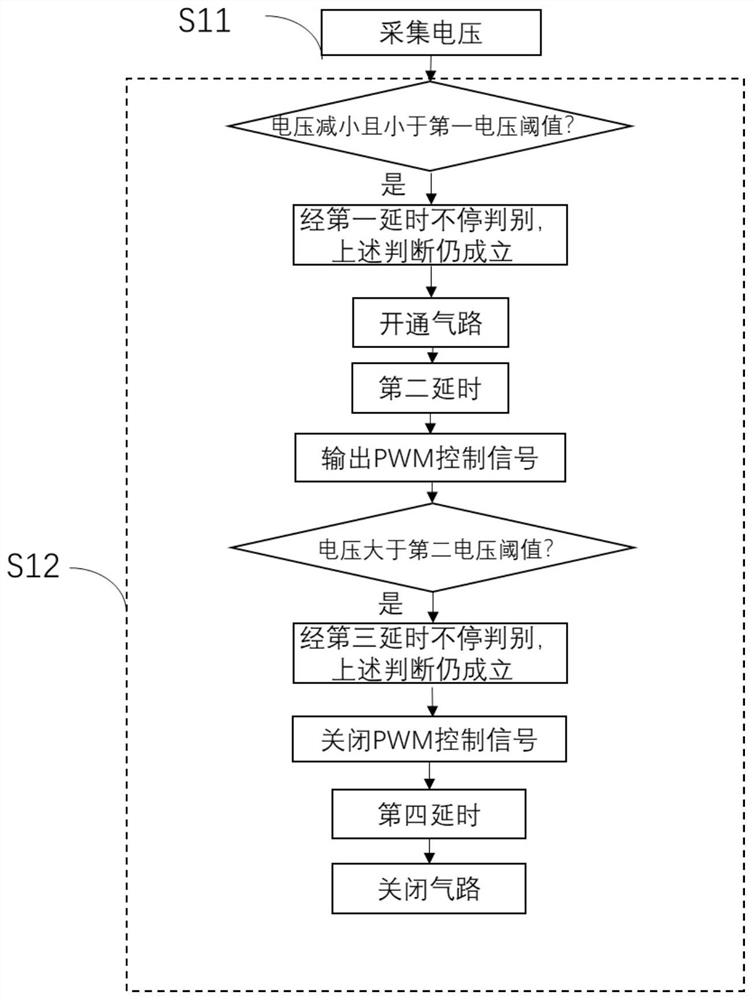

[0090] see image 3 , the present embodiment provides a gas path control method for an argon arc welding machine, which is applied to the aforementioned gas path control system for argon arc welding machines, including the following steps:

[0091] S11: collecting the voltage of the argon arc welding machine;

[0092] S12: Control the gas circuit, voltage and current of the argon arc welding machine according to the voltage.

[0093] In this embodiment, the controlling the gas path, voltage and current S12 of the argon arc welding machine according to the voltage and current includes:

[0094] The gas path of the argon arc welder is controlled by the electromagnetic gas valve 40, and the voltage and current of the argon arc welder are controlled by the PWM control signal.

[0095] In this embodiment, the controlling the gas path, voltage and current S12 of the argon arc welding machine according to the voltage includes:

[0096] The magnitude of the voltage is judged by a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com