Integrally-welded movable pressure support

A pressure and welding point technology, applied in the field of integrated welding movable pressure bracket, can solve the problems of loose screw fastening, loose overall structure of the machine, user safety risks, etc., to avoid loose structure, reduce labor links, The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

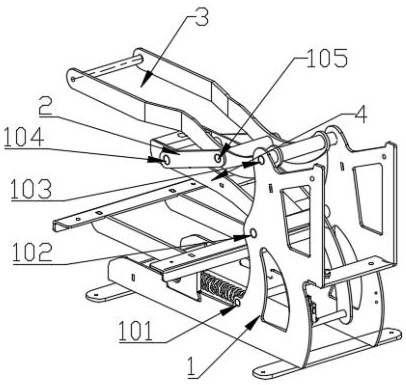

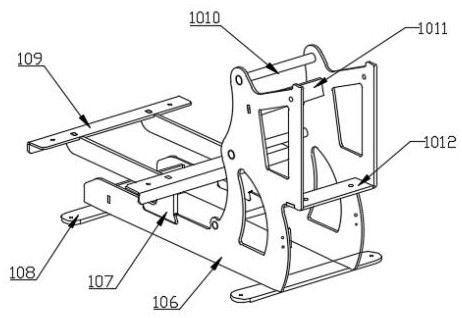

[0029] As a preferred embodiment of the present invention, the connection between the second rotating mechanism 3 and the frame 1 is a second welding point 102, and the connection between the first rotating mechanism 4 and the frame 1 is a third welding point. Welding point 103 , the connection between the connecting mechanism 2 and the first rotating structure 4 is the fourth welding point 104 , and the connecting point between the second rotating mechanism 3 and the connecting mechanism 2 is the fifth welding point 105 .

[0030] Specifically, the bottom of the frame 1 is further provided with a first welding point 101 .

[0031] The technical solution provides an integrated welded movable pressure bracket, including a frame, on which the second rotating mechanism and the first rotating mechanism are rotatably connected, and the connecting mechanism between the first rotating mechanism and the second rotating mechanism is rotatably connected. On the basis of the structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com