Coal mine underground halogen-free flame-retardant antistatic fiber woven cloth and preparing method of fiber woven cloth

A flame-retardant, anti-static, and fiber weaving technology, which is applied to braids, mining equipment, and earthwork drilling and mining, can solve problems that do not conform to environmental protection and application safety concepts, high labor intensity of workers, and inconvenient installation and use, so as to facilitate mechanization Construction, construction is convenient and efficient, and the effect of using fewer layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

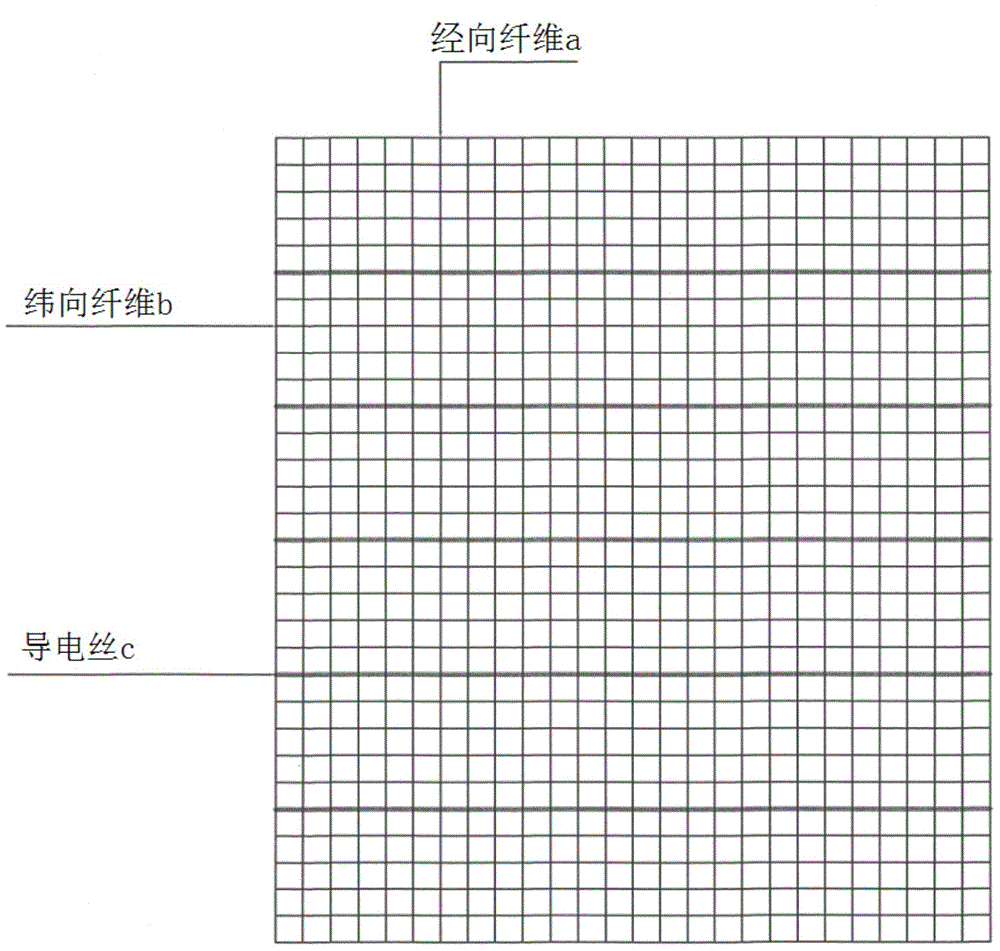

Method used

Image

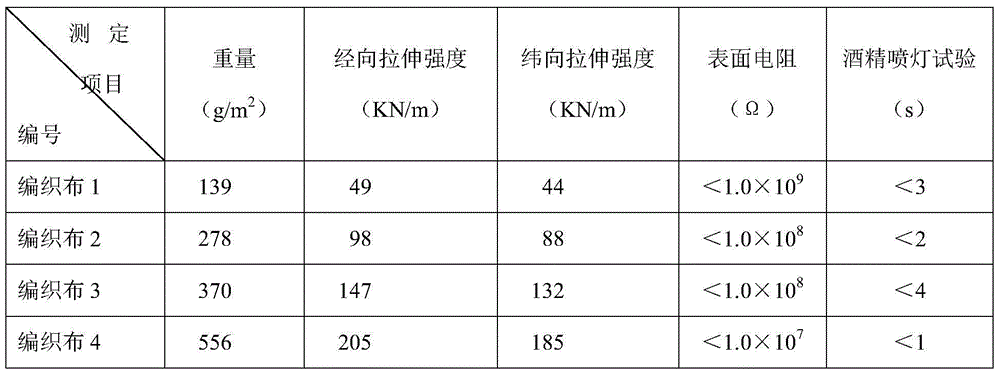

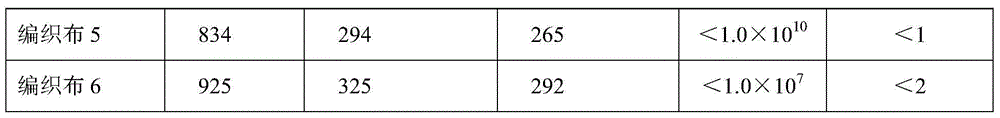

Examples

Embodiment 1

[0035] (1) Selecting a phosphorus content of 5000ppm halogen-free flame-retardant polymer chips;

[0036] (2) increasing the intrinsic viscosity of the halogen-free flame-retardant polymer chip described in step (1) to 0.95dl / g through solid-phase thickening;

[0037] (3) Spinning and stretching the thickened said halogen-free flame-retardant polymer slice to obtain a halogen-free flame-retardant fiber industrial yarn with a fineness of 555 dtex;

[0038] (4) performing ply twisting with the said halogen-free flame retardant fiber industrial yarn obtained in the step (3) and the carbon black fiber matrix composite conductive yarn of 44dtex, the twist is 100 twists to make the conductive yarn for embedded weaving;

[0039] (5) The conductive yarn for inlay weaving prepared in step (4) is weaved in the weft direction, and the halogen-free flame-retardant fiber industrial yarn prepared in step (3) is woven with a distance of 3.0 cm. A halogen-free flame-retardant antistatic fibe...

Embodiment 2

[0041] (1) Selecting a halogen-free flame-retardant polymer chip with a phosphorus content of 6000ppm;

[0042] (2) increasing the intrinsic viscosity of the halogen-free flame-retardant polymer chip described in step (1) to 0.95dl / g through solid-phase thickening;

[0043] (3) Spinning and stretching the thickened said halogen-free flame-retardant polymer slice to obtain a halogen-free flame-retardant fiber industrial yarn with a fineness of 1111dtex;

[0044] (4) The halogen-free flame-retardant fiber industrial yarn obtained in the step (3) and the carbon black fiber matrix composite conductive yarn of 22dtex are ply twisted, and the twist is 75 twists, and the conductive yarn for embedded weaving is obtained;

[0045] (5) The conductive yarn for inlay weaving prepared in step (4) is weaved in the weft direction, and the halogen-free flame-retardant fiber industrial yarn prepared in step (3) is woven with a distance of 2.0 cm, and is woven into The density is 30×30 pieces / ...

Embodiment 3

[0047] (1) Selecting a halogen-free flame-retardant polymer chip with a phosphorus content of 4000ppm;

[0048] (2) increasing the intrinsic viscosity of the halogen-free flame-retardant polymer chip described in step (1) to 1.05dl / g through solid-phase thickening;

[0049] (3) Spinning and stretching the thickened said halogen-free flame-retardant polymer slice to obtain a halogen-free flame-retardant fiber industrial yarn with a fineness of 1667dtex;

[0050] (4) Plying and twisting the halogen-free flame-retardant fiber industrial yarn obtained in step (3) and the carbon black fiber matrix composite conductive yarn of 22dtex, the twist is 60 twists, and the conductive yarn for embedded weaving is obtained;

[0051] (5) The conductive yarn for inlay weaving prepared in step (4) is weaved in the weft direction, and the halogen-free flame-retardant fiber industrial yarn prepared in step (3) is woven with a distance of 1.5 cm. A halogen-free flame-retardant antistatic fiber wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com