Halogen-free flame-retardant antistatic polyester mesh false roof for underground coal mine and preparation method thereof

A flame-retardant, anti-static, and flame-retardant polyester technology, which is used in the manufacture of fire-retardant and flame-retardant filaments, mining equipment, and single-component polyester rayon. and other problems, to achieve the effect of quick product installation, simple production process and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

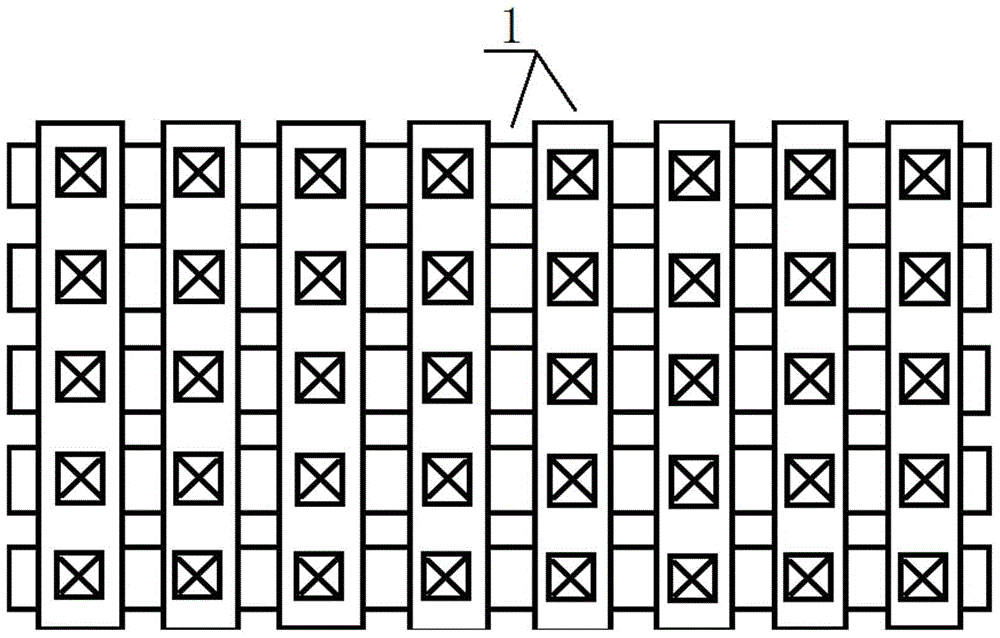

[0055] Reference figure 1 , The preparation method of the top belt 1 includes the following steps:

[0056] (1) The phosphorus-based reactive flame retardant is copolymerized with terephthalic acid and ethylene glycol to obtain a halogen-free flame-retardant polyester chip with a phosphorus content of 5000 ppm;

[0057] (2) Increase the intrinsic viscosity of the halogen-free flame-retardant polyester chips described in step (1) from 0.67dl / g to 0.95dl / g through solid phase viscosity increase;

[0058] (3) The tackified halogen-free flame-retardant polyester chips are spun and stretched to obtain halogen-free flame-retardant polyester industrial filaments with a fineness of 888 dtex;

[0059] (4) The halogen-free flame-retardant polyester industrial filament obtained in step (3) is woven into a top belt with a width of 22 mm and a thickness of 2.0 mm through a woven belt;

[0060] (5) Put the top tape obtained in step (4) into a 2%wt antistatic solution for 30 seconds and then take it o...

Embodiment 2

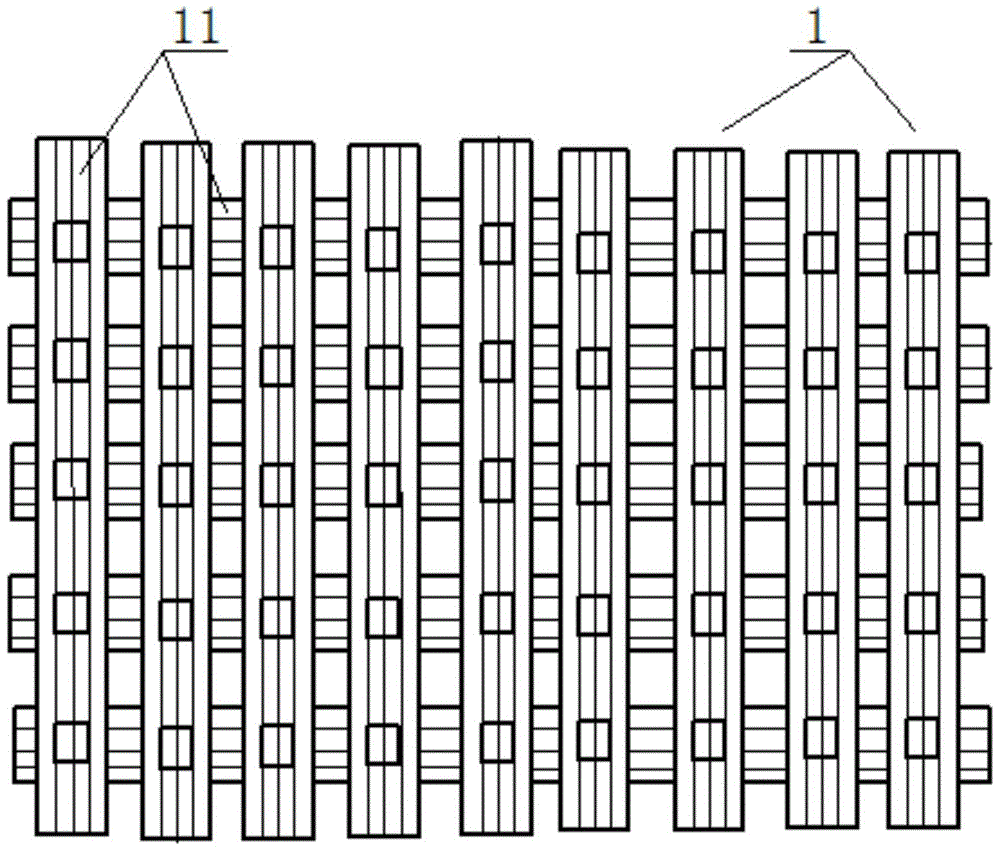

[0062] Reference figure 2 , The preparation method of the top belt 1 includes the following steps:

[0063] (1) The phosphorus-based reactive flame retardant is copolymerized with terephthalic acid and ethylene glycol to obtain a halogen-free flame-retardant polyester chip with a phosphorus content of 6000 ppm;

[0064] (2) Increase the intrinsic viscosity of the halogen-free flame-retardant polyester chips described in step (1) from 0.67dl / g to 1.00dl / g through solid phase viscosity increase;

[0065] (3) The tackified halogen-free flame-retardant polyester chips are stretched by spinning to obtain halogen-free flame-retardant polyester industrial filaments with a fineness of 1667 dtex;

[0066] (4) Ply and twist the halogen-free flame-retardant polyester industrial filament obtained in step (3) and 22dtex conductive yarn, with a twist of 60 twists, to obtain a conductive yarn for inlay weaving;

[0067] (5) The conductive thread 11 obtained in step (4) is interwoven radially with th...

Embodiment 3

[0069] The preparation method of the top belt includes the following steps:

[0070] (1) The phosphorus-based reactive flame retardant, terephthalic acid and ethylene glycol are copolymerized to obtain halogen-free flame-retardant polyester chips with a phosphorus content of 4000 ppm;

[0071] (2) Increase the intrinsic viscosity of the halogen-free flame-retardant polyester chips described in step (1) from 0.67dl / g to 0.95dl / g through solid phase viscosity increase;

[0072] (3) The tackified halogen-free flame-retardant polyester chips are spun and stretched to obtain halogen-free flame-retardant polyester industrial filaments with a fineness of 999 dtex;

[0073] (4) The halogen-free flame-retardant polyester industrial filament obtained in step (3) is woven into a top belt with a width of 15 mm and a thickness of 1.0 mm through a woven belt.

[0074] (5) Put the top tape obtained in step (4) into a 5% wt antistatic solution for 30 seconds and then take it out, and put the top tape s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com