Steel ring type high-strength buttress column with built-in light material

A lightweight material, steel ring technology, applied in pillars/supports, mining equipment, earth-moving drilling, etc., can solve problems such as increased construction insecurity, secondary disasters, and more manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, by describing embodiment, the present invention will be further described:

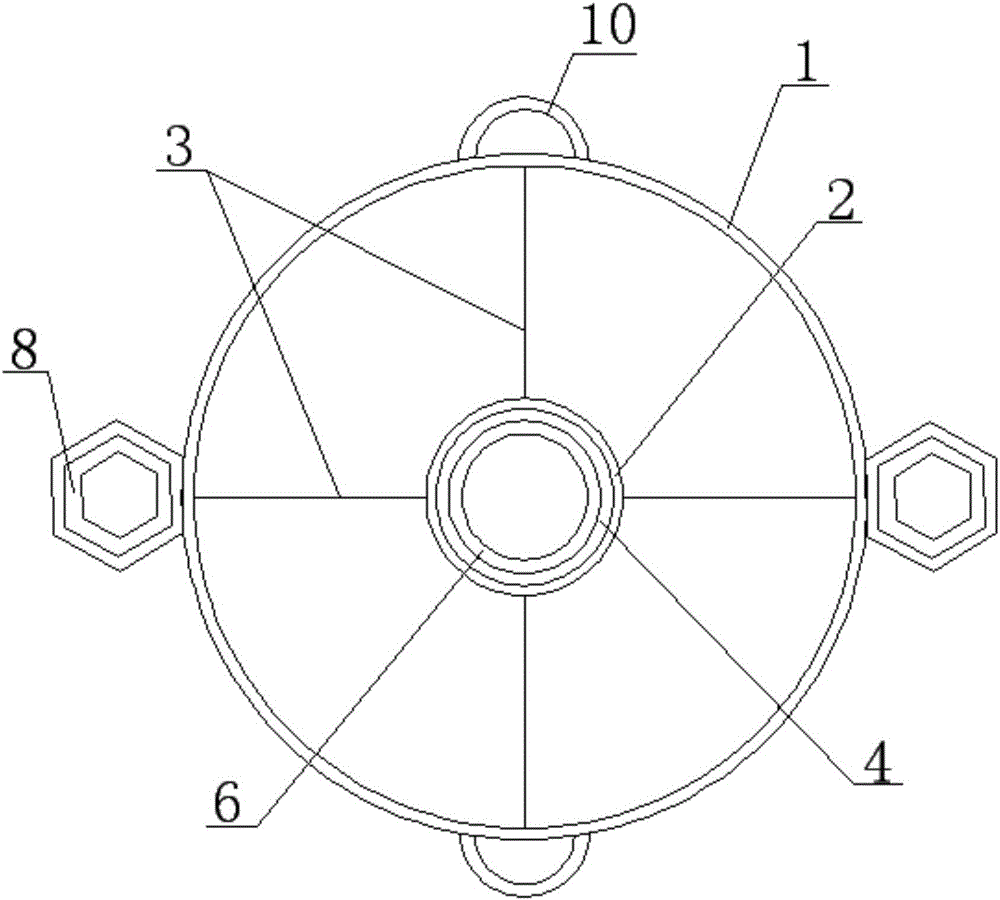

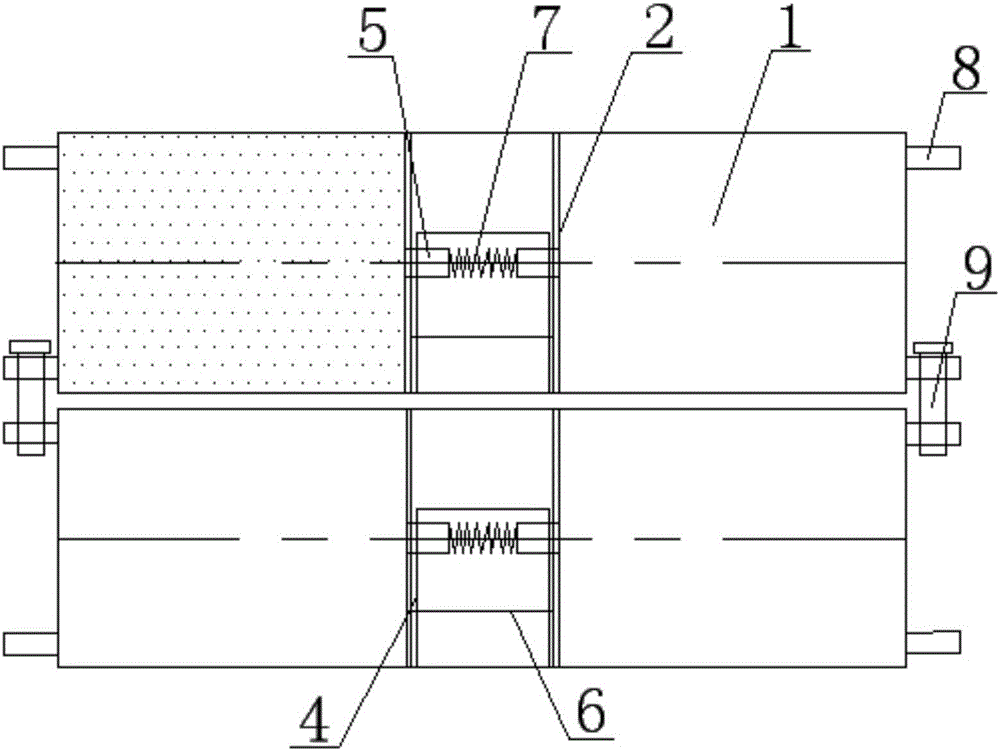

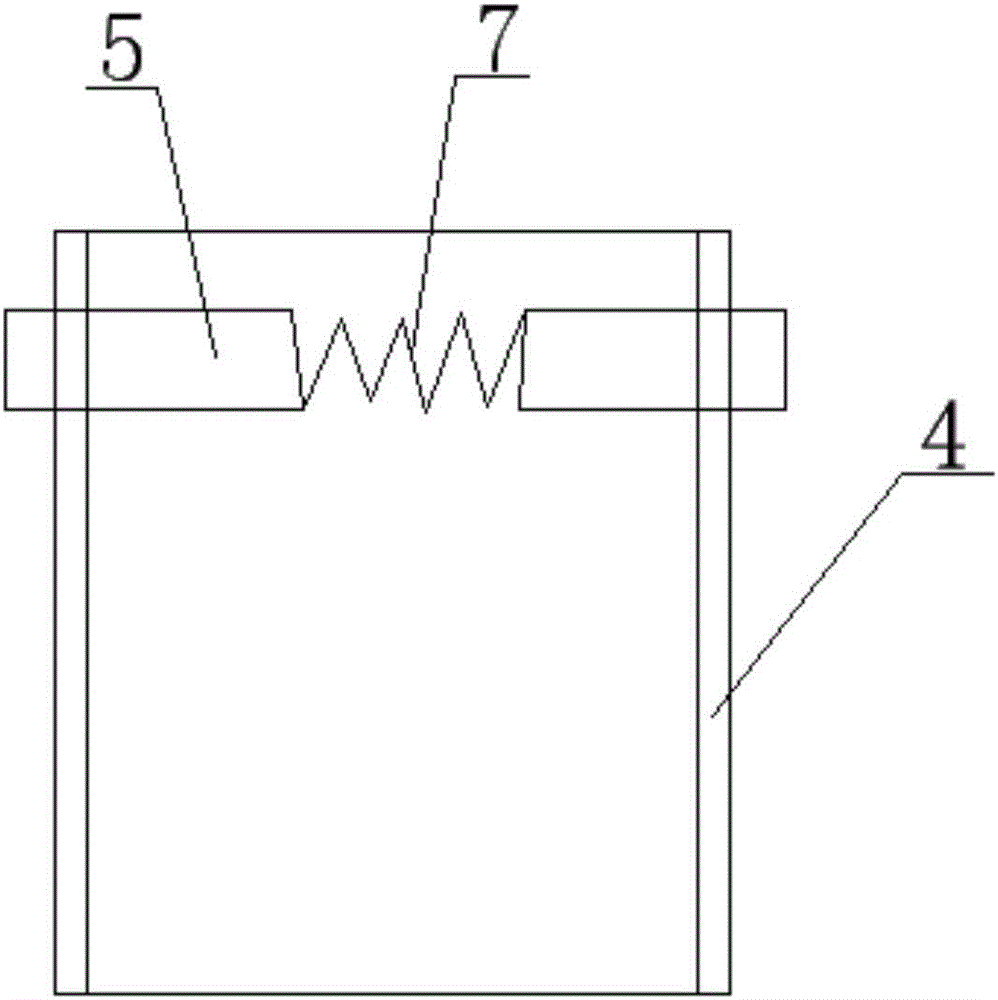

[0016] Such as Figures 1 to 3 As shown, the steel ring type built-in light material high-strength stacking column of the present invention includes several steel rings 1 with a diameter of 200-800 mm, a wall thickness of 3-12 mm, and a height of 100-500 mm. The strength requirements of the steel ring 1 are determined. All the steel rings 1 are stacked up and down in order to form a pile. Each steel ring 1 is equipped with a steel pipe 2. The steel pipe 2 is located at the center of the inner ring of the steel ring 1, and the steel pipe 2 passes through the reinforcing rib 3 or the reinforcing rib. The plate is welded to the inner wall of the steel ring 1, and each steel ring 1 is filled with light-weight high-strength materials. The high-strength material is made of super-polymeric concrete. Note, from 30-50 parts of polyethylene glycol ether, 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com