Non-metal flame-retardant lining block structure for railway tank car and preparation method thereof

A non-metal and lining block technology is applied to the non-metallic flame retardant lining block structure and preparation field for railway tank cars. , The effect of simple installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present application with reference to the accompanying drawings in the embodiments of the present application. Obviously, the described embodiments are only for illustration, and are not intended to limit the present application.

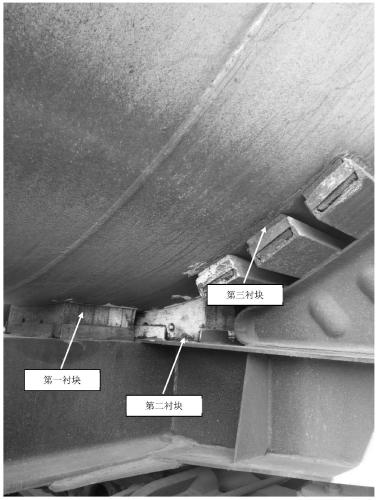

[0026] The basic idea of the non-metallic flame-retardant lining block for railway tank car disclosed by the present invention is to take the polymer material as the main body, and consider the performance requirements of preventing combustion, compressive strength and wear resistance during use, and carry out The corresponding internal skeleton structure is designed, and the corresponding components are added to modify the polymer material. At the same time, according to the shape and characteristics of the oil tank, the pad structure is designed to improve the fixing strength.

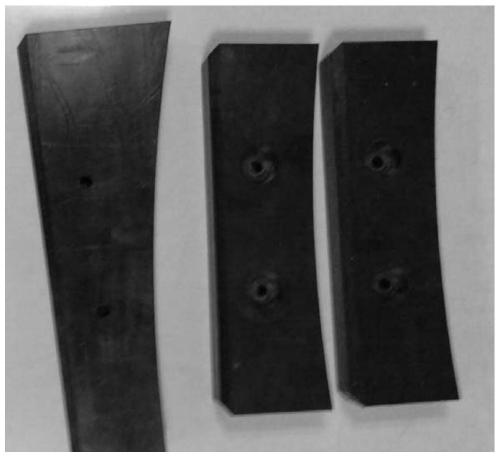

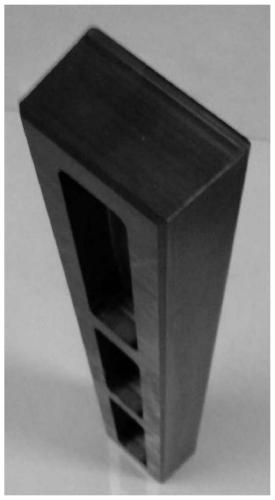

[0027] Such as Figure 1-9 As shown, the non-metallic flame-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com