Fixing frame

A fixed frame and straight rod technology, which is applied in the field of fixed frames, can solve the problems of large-scale processing machinery occupying a large space, cumbersome manual links, inconvenient transfer, etc., and achieves good overall structural stability, wide applicability, and reduction of manual links. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

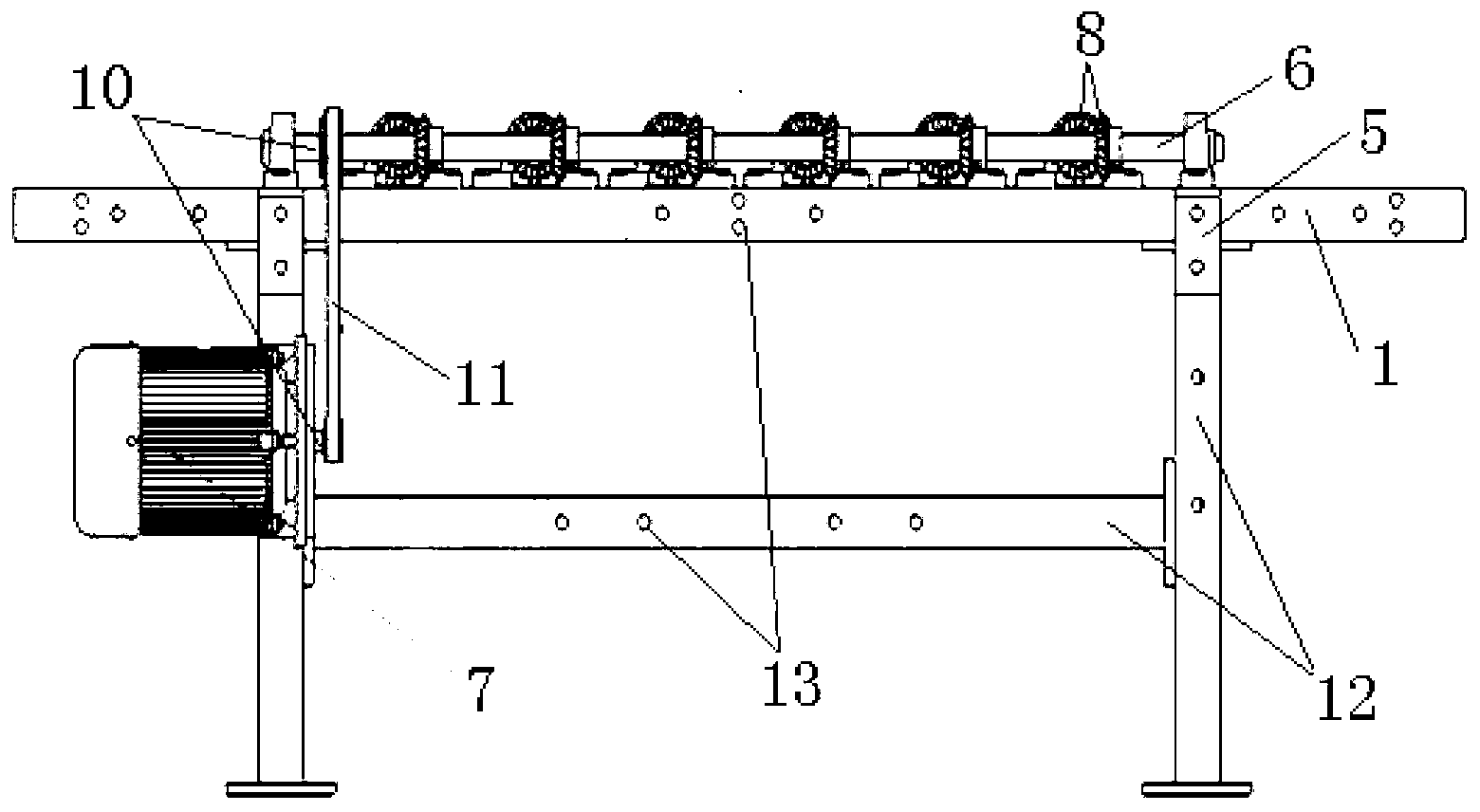

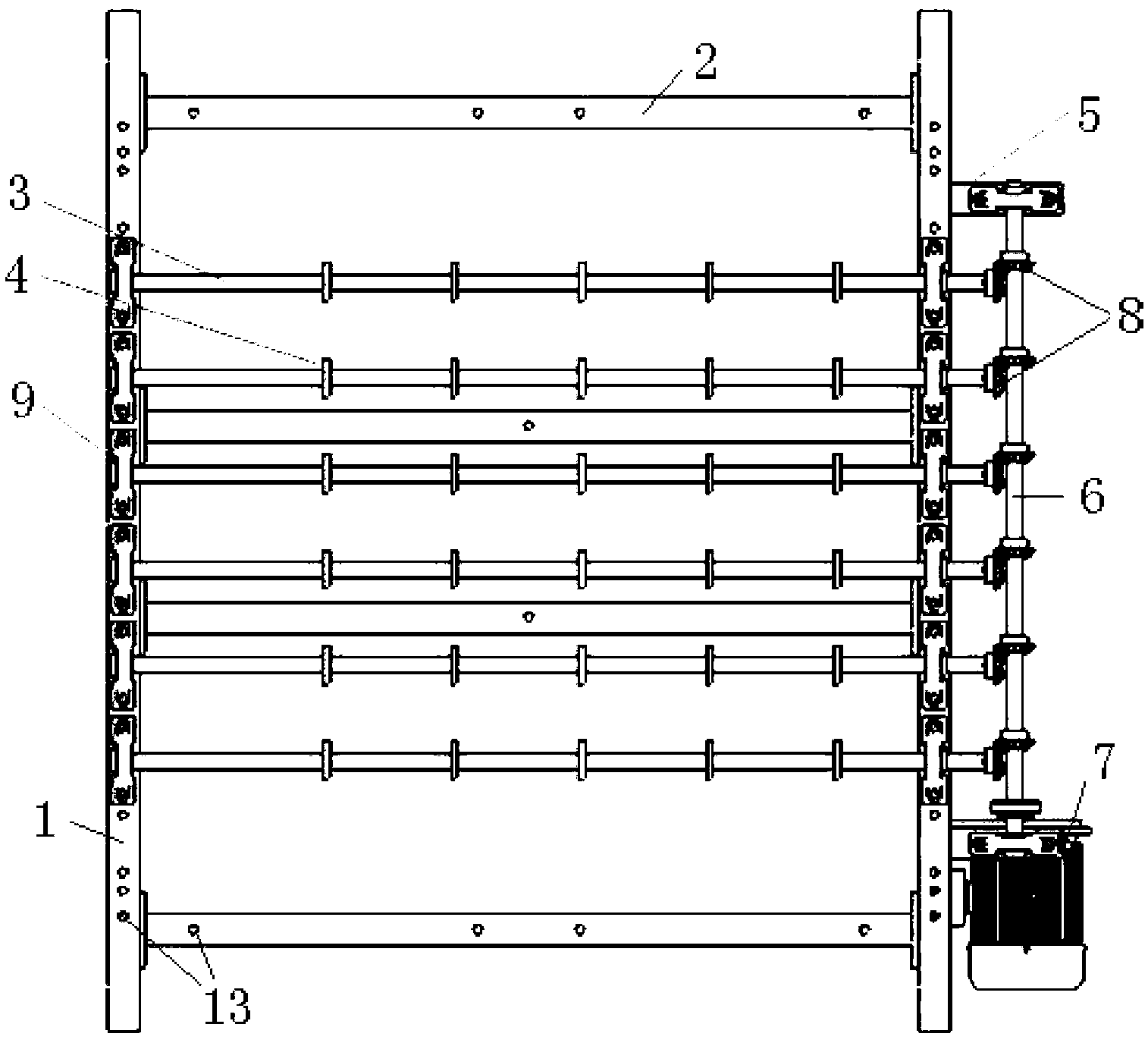

[0026] figure 1 is a schematic diagram of the side structure of the fixing frame in the preferred embodiment of the present invention, figure 2 It is a top view structural schematic diagram of the fixing frame of the preferred embodiment of the present invention, as figure 1 , 2 As shown, the fixed frame includes a support straight bar 1 and a support cross bar 2, at least two support cross bars 2 are equidistantly fixed between at least two support straight bars 1, and at least two support straight bars 1 are also provided with at least Two support rollers 3, at least two support rollers 4 are arranged at equal intervals on the support roller 3, a bearing seat bracket 5 is provided on one side of the supporting straight rod 1, a transmission rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com