Method for smelting silicon carbide by single core furnace

A silicon carbide, single-core technology, applied in the field of smelting silicon carbide, can solve the problems of high energy consumption, low output and quality, and high control technology requirements, and achieve the effects of increasing product output, avoiding blindness, and reducing control technology requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

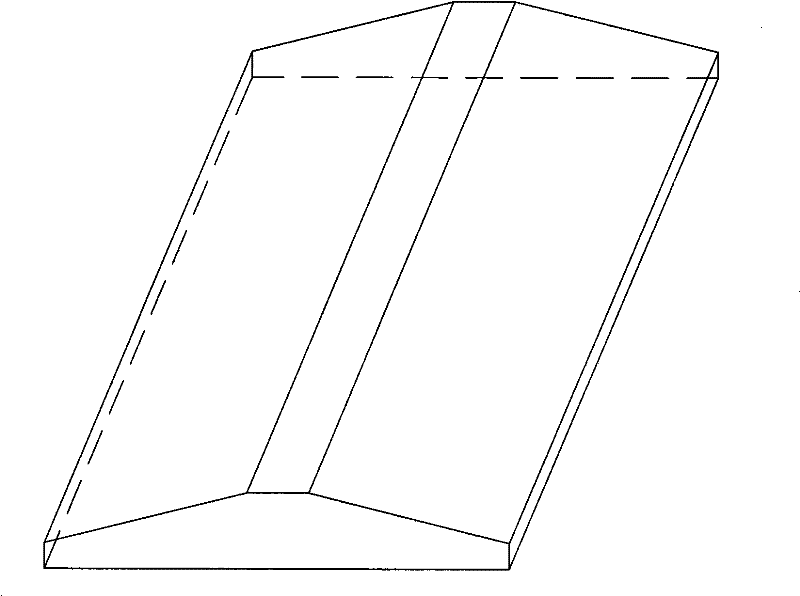

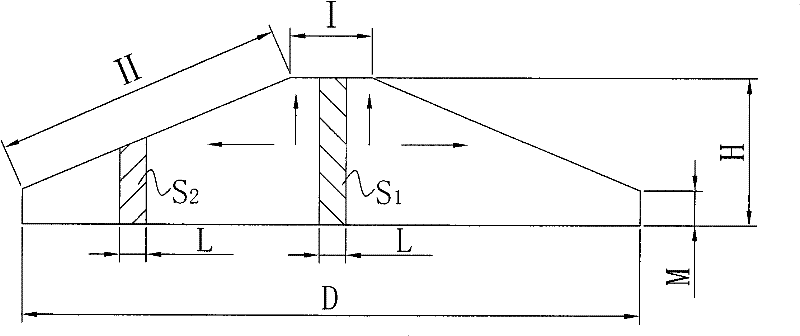

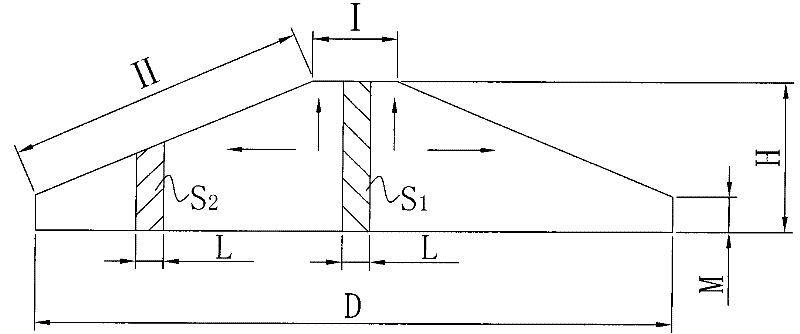

[0021] In the method for smelting silicon carbide involved in the present invention, first, the furnace core 1 needs to be processed to form a central gasification zone I and a peripheral sintering zone II on the outer heat-conducting surface of the furnace core 1; secondly, in order to ensure that the furnace core 1 forms a central gas The thickness H of the gasification zone in the center of the furnace core is greater than the thickness M of the two sides of the furnace core in the sintering zone I and the surrounding sintering zone II; finally, the two ends of the furnace core 1 are heated with electrodes until the gasification zone I in the center of the furnace core 1 occurs. The phenomenon of gasification and evaporation is used to reach the required temperature, and then the reaction materials are fully reacted in the furnace to be smelted into silicon carbide.

[0022] In order to improve the smelting effect, the thickness H of the gasification zone in the center of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com