Suspended formwork bracing system for steel structure concrete floor slab construction

A technology of formwork support and support system, which is applied in the direction of formwork/formwork/work frame, building structure, and on-site preparation of building components, which can solve the problems of long construction period and heavy workload, and achieve convenient formwork support Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

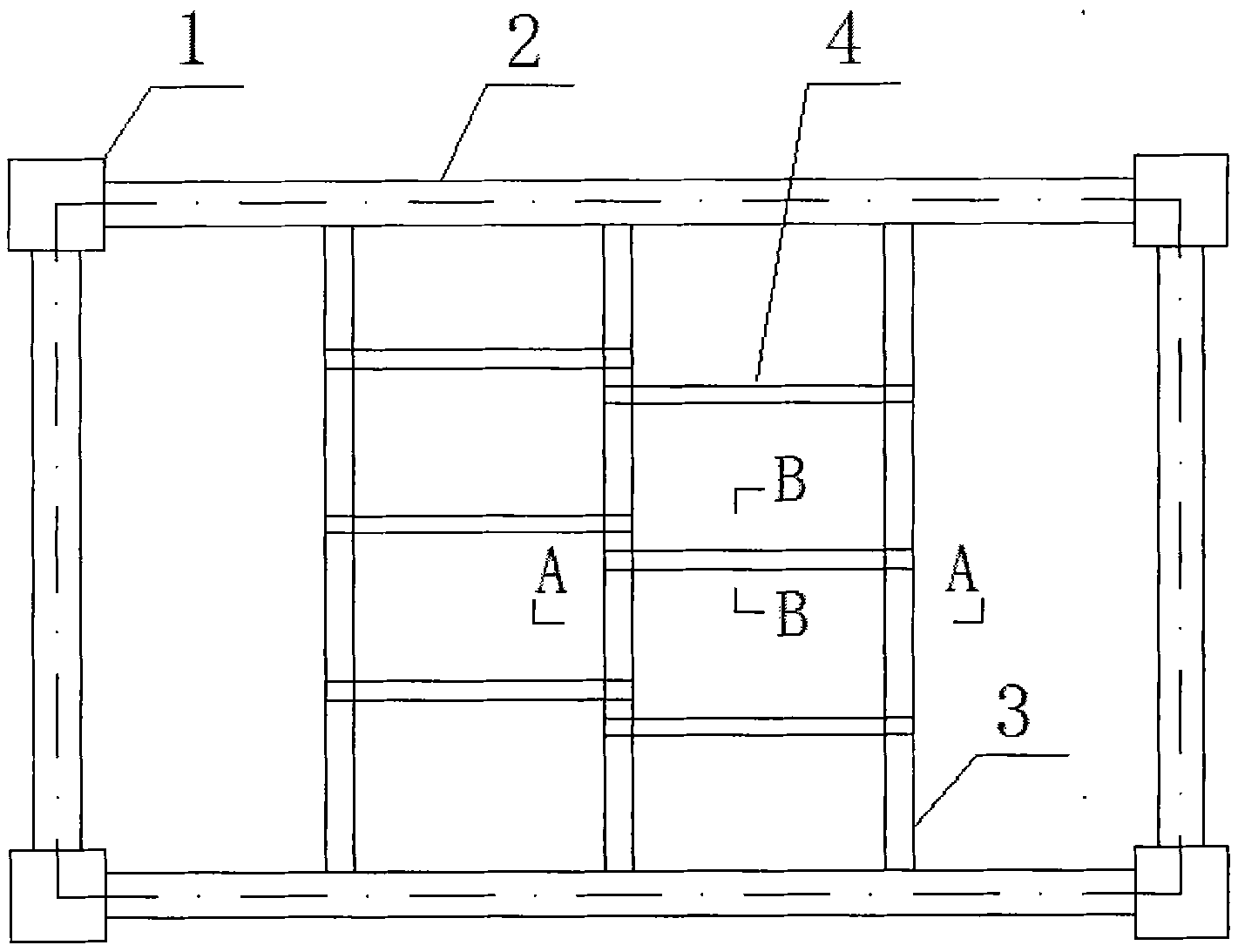

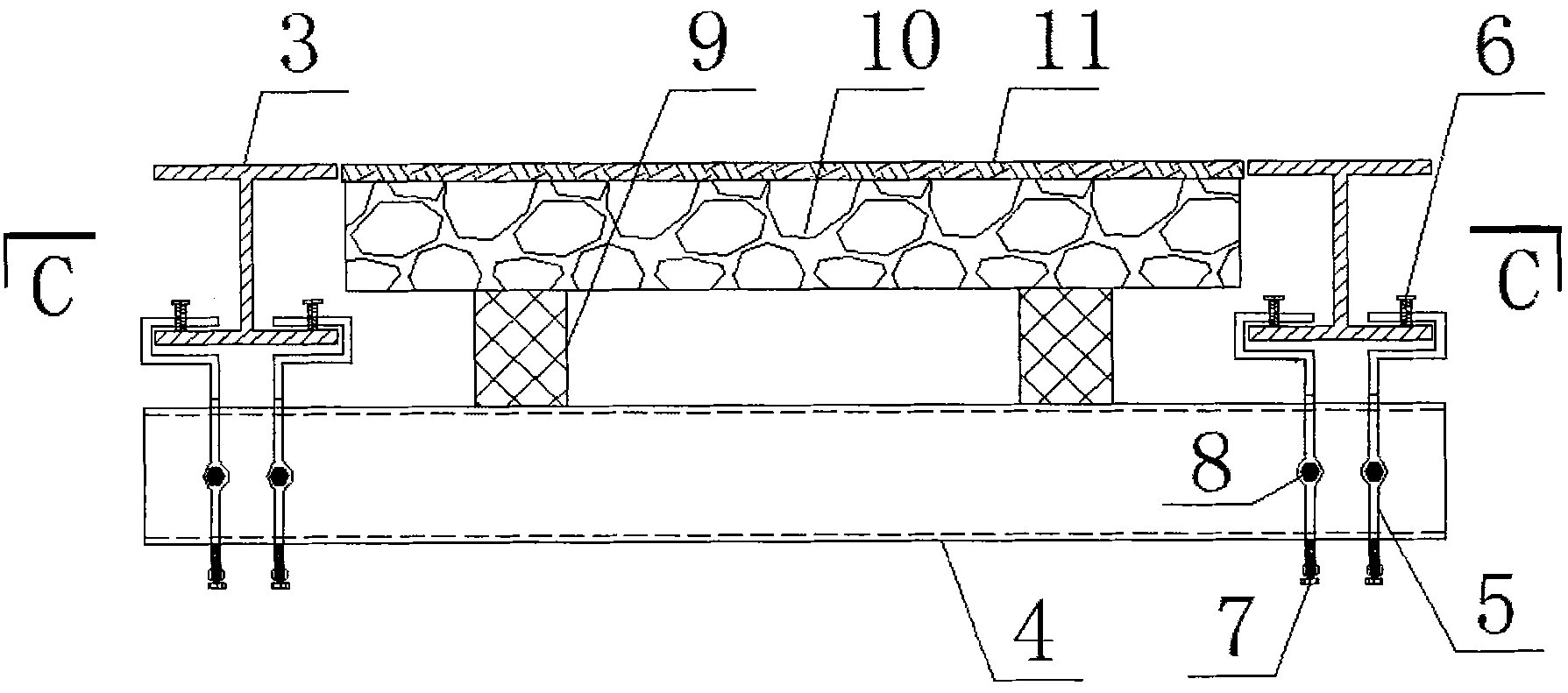

[0014] The preferred embodiment of the suspension formwork support system for steel structure concrete floor construction of the present invention is:

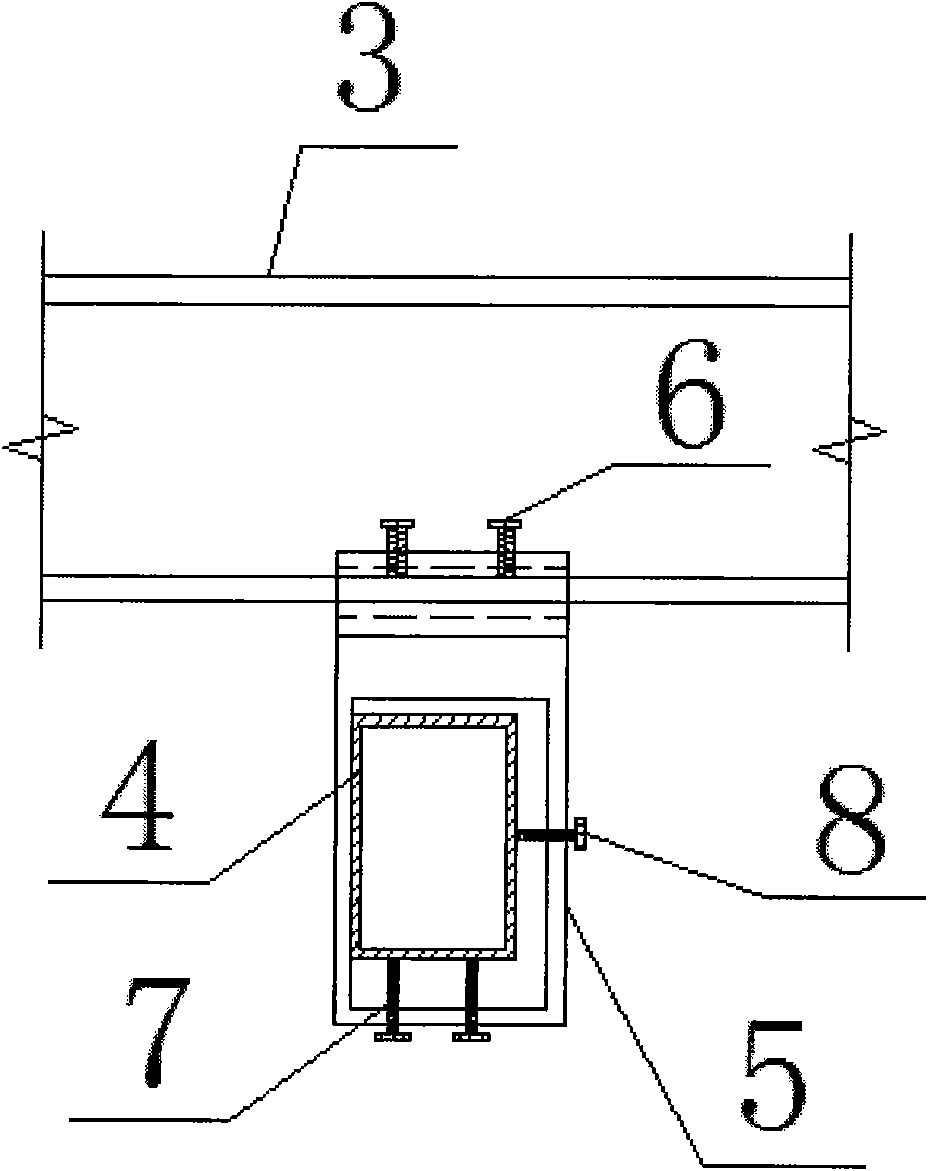

[0015] The formwork support beam is included, and the formwork support beam is suspended on the lower flange of the H-shaped steel beam of the steel structure concrete floor slab. The two ends of the formwork support beam can be respectively hung on the lower flanges of the two H-shaped steel beams through clips. Fastening bolts can be arranged between the clip and the lower flange of the H-shaped steel beam.

[0016] There can be two clips, which are respectively suspended on both sides of the lower flange of the H-shaped steel beam; there can also be one clip, which is suspended on one side of the lower flange of the H-shaped steel beam.

[0017] Horizontal fixing bolts can be provided between the clip and the formwork support beam in the horizontal direction, and vertical lifting bolts can be provided in the vertical direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com