Forced ventilation one-way valve for automotive engine

An automotive engine and forced ventilation technology, applied in engine components, machines/engines, crankcase ventilation, etc., can solve the problem of irregular opening and closing of plunger valves, affecting the normal operation of the engine, and unstable opening and closing of check valves, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below by embodiment and accompanying drawing thereof, the present invention is described in further detail:

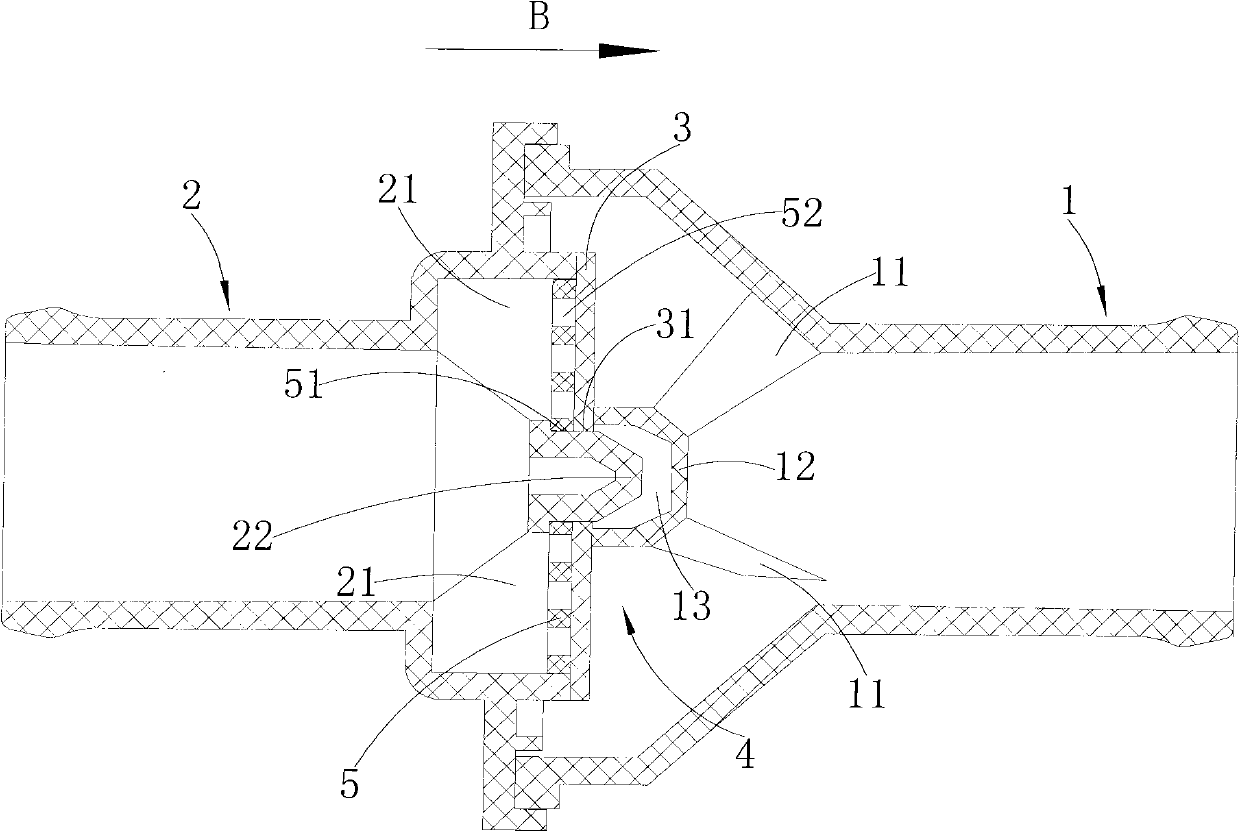

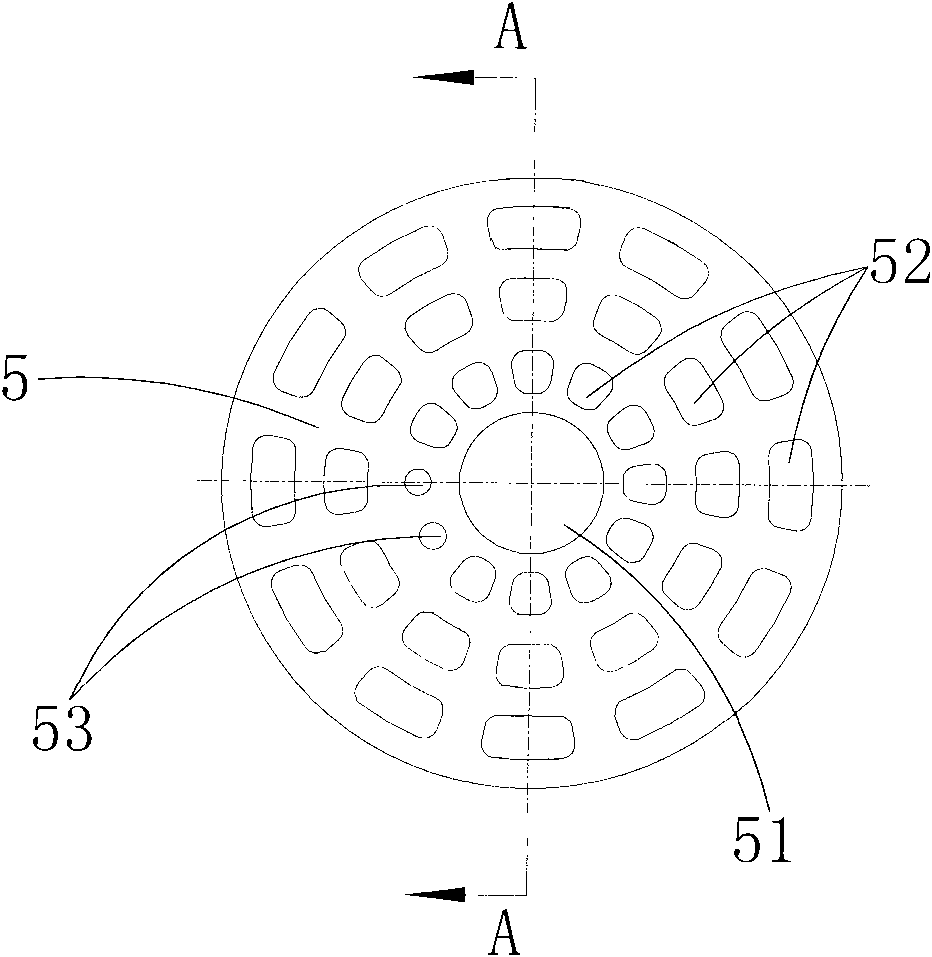

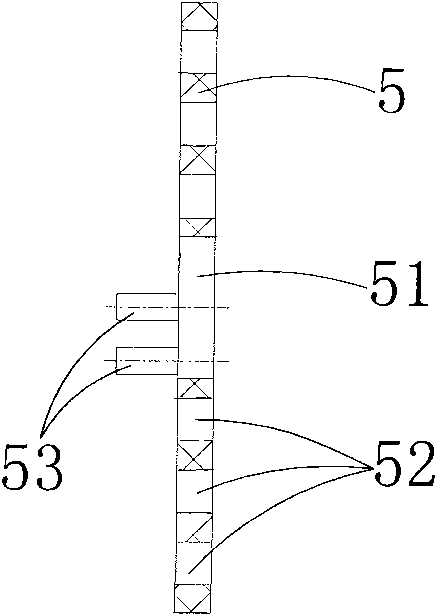

[0027] see figure 1 one image 3 : The one-way valve includes a valve cover 1, a valve seat 2, a circular valve plate 3, the valve cover 1 and the valve seat 2 are sealed and connected and a valve cavity 4 is formed between the valve cover 1 and the valve seat 2, the valve seat 2, the valve cavity 4. The bonnets 1 are connected sequentially, and the valve plate 3 is placed in the valve cavity 4 , and the valve cavity 4 is also provided with a circular blocking plate 5 which acts as a barrier to the valve plate 3 .

[0028] The valve seat 2 is a cylindrical body with openings at both ends. There are six first spokes 21 and a first hub 22 on the side close to the valve cover 1. The first spokes 21 are evenly distributed on the inner wall of the valve seat 2 in the circumferential direction and close The end faces of the valve cover 1 share a common plane, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com