Blade rotating device for comprehensive performance test of fan blades

A comprehensive performance test and fan blade technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of loss of accuracy of measured data, cumbersome testing process, and damage to the tested blades, and achieve the goal of testing The process is convenient, the difficulty of design and manufacturing is reduced, and the effect is not easy to be damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

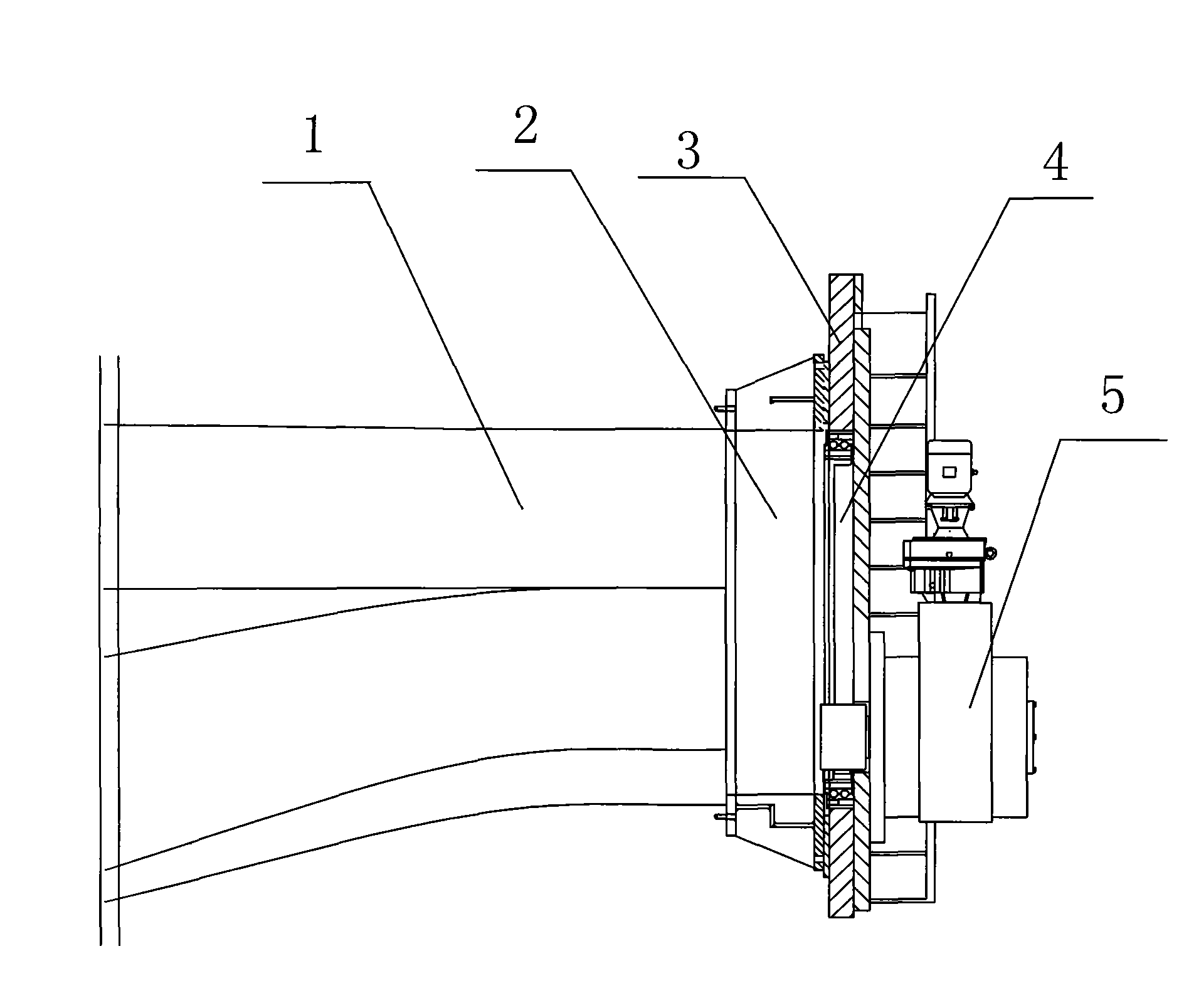

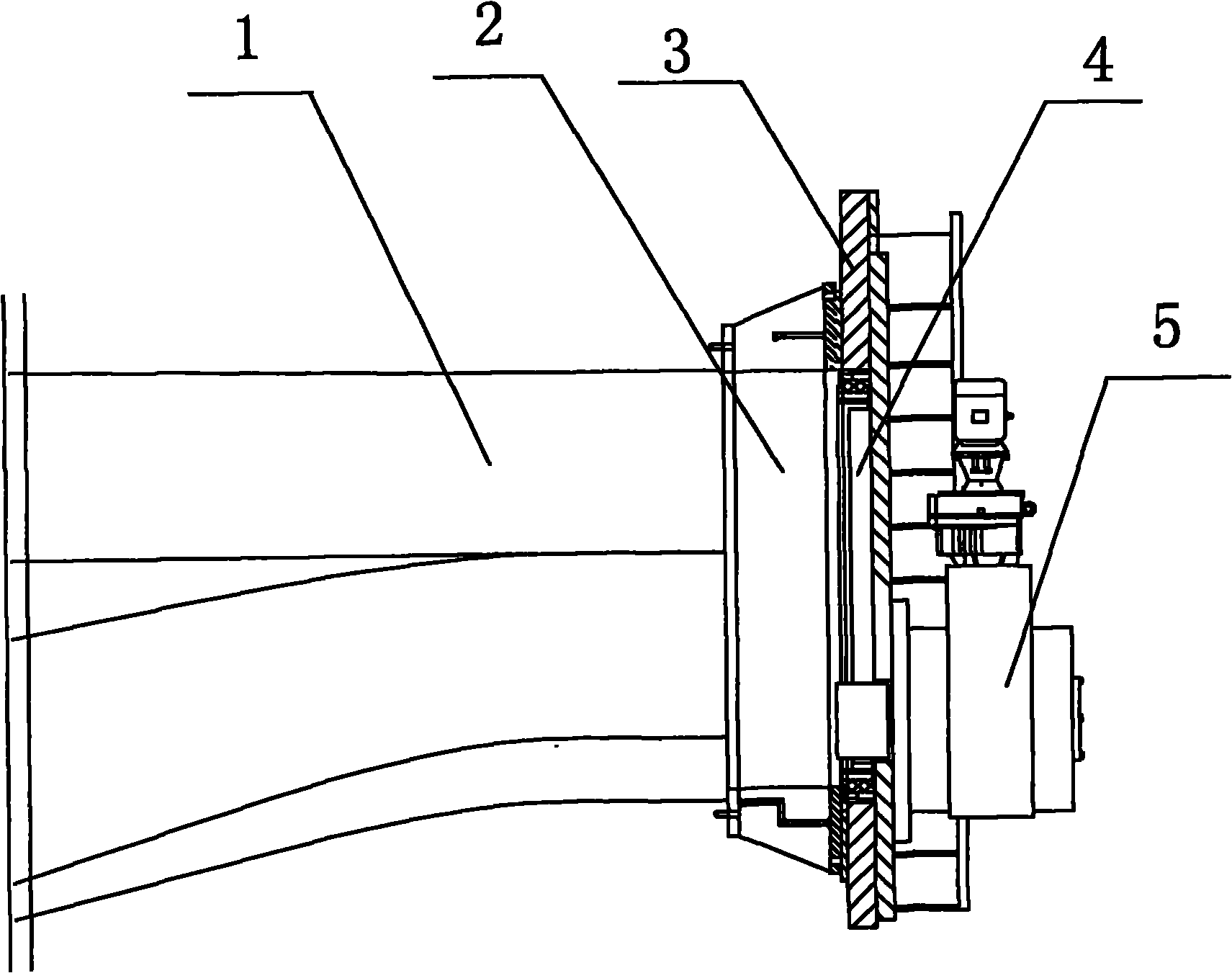

[0011] Embodiment 1, with reference to figure 1 . A blade rotating device for comprehensive performance testing of fan blades, which includes a fixed base 3, a worm drive system 5, a slewing bearing 4 and a rotor locking disc 2; the slewing bearing 4 is installed on the fixed pedestal 3, and the The rotor locking disc 2 is fixedly connected with the slewing bearing 4, the power output end of the worm drive system 5 is connected with the slewing bearing 4, and both the rotor locking disc 2 and the fixed base 3 are provided with screw holes.

[0012] During the test, the blade 1 to be tested can be fixed on the rotor locking disk 2 through bolts and screw holes, and the slewing bearing 4 is driven to rotate through the worm drive system 5, thereby driving the blade 1 to continuously change the angle; when the blade 1 reaches the required angle Finally, the rotor locking disc 2 is fixed on the fixed base 3 through bolts and screw holes. When using the loading system to load the...

Embodiment 2

[0013] Example 2. In the blade rotating device for comprehensive performance testing of fan blades described in Example 1, the fixed base 3 is composed of two layers of steel plates, the slewing bearing 4 is installed between the two layers of steel plates, and the slewing bearing 4 is fixed by bolts on the back plate.

Embodiment 3

[0014] Example 3. In the blade rotating device for comprehensive performance testing of fan blades described in Embodiment 2, the power output end of the worm drive system 5 passes through the rear steel plate and is connected to the slewing bearing 4 through gear meshing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com