Lifting mechanism of forging manipulator

A technology for a forging manipulator and a buffer device, which is used in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problem of reducing the forging quality of forgings, increasing the structural complexity, and failing to achieve lateral movement, etc. problems, to achieve the effect of improving forging quality, simplifying structure and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

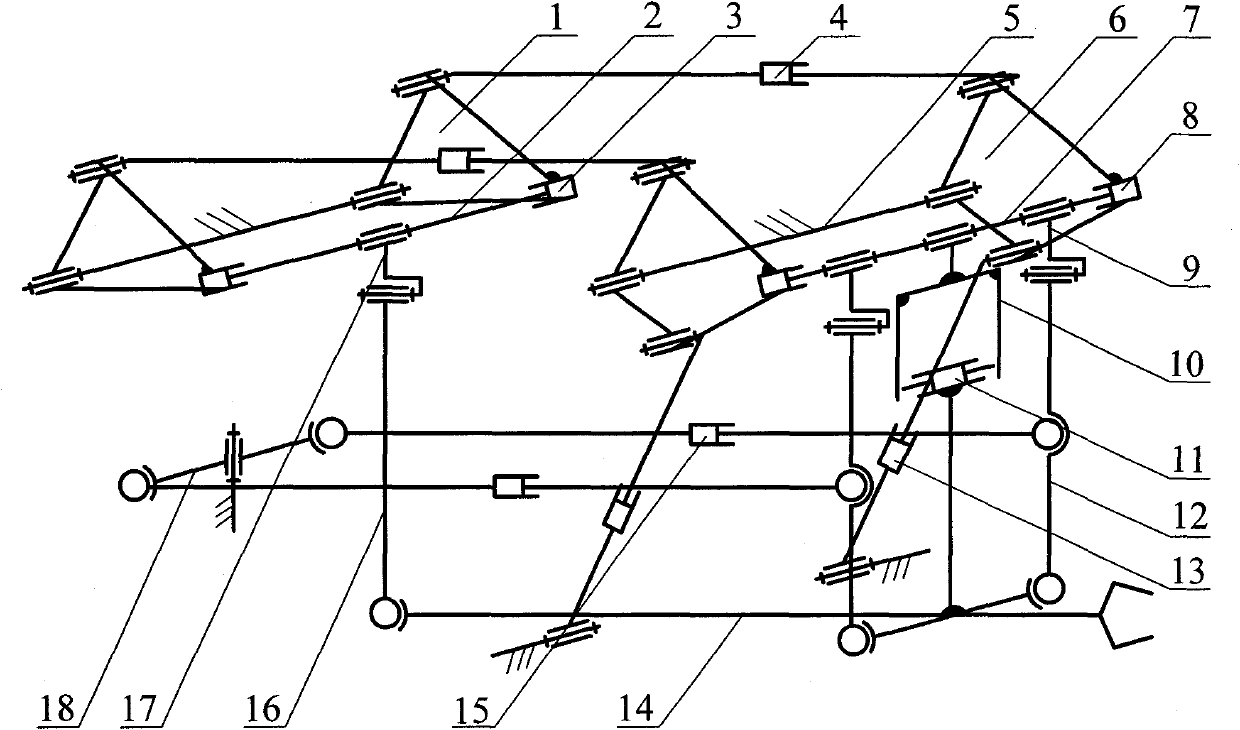

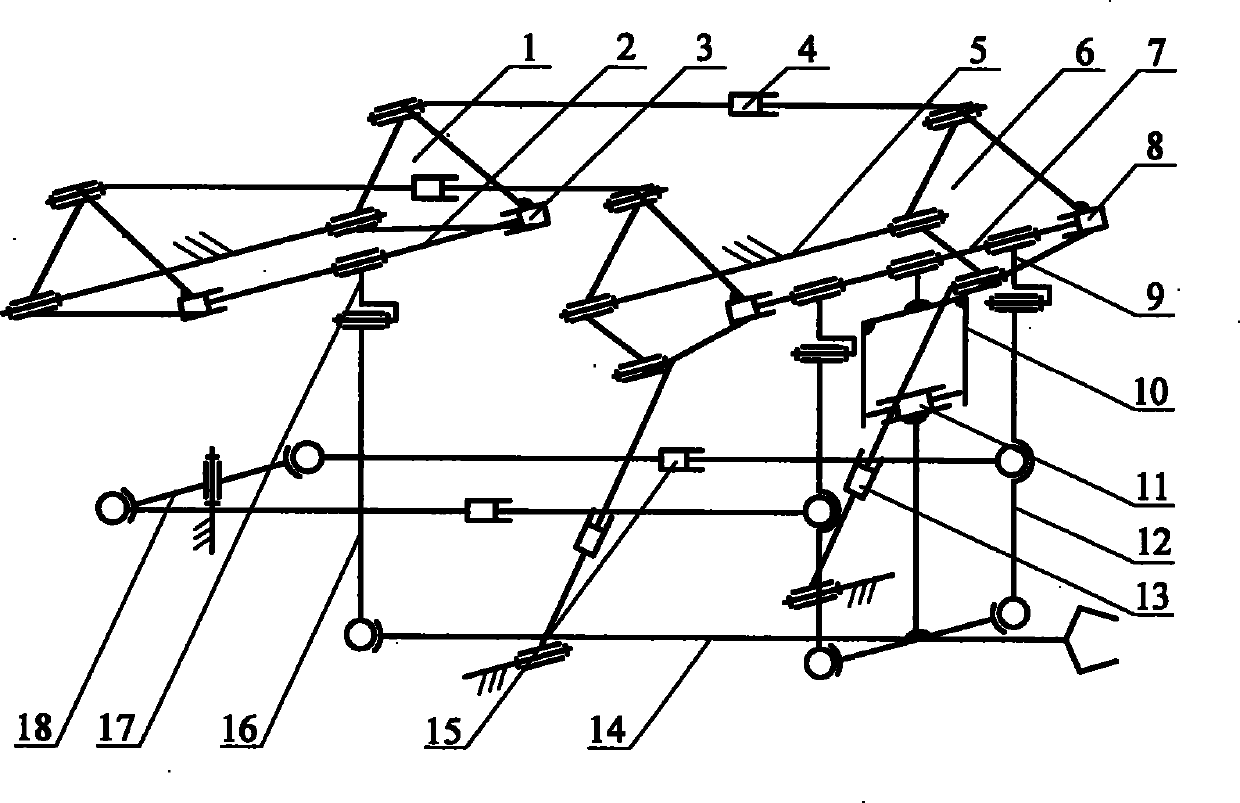

[0014] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

[0015] As shown in the drawings, this embodiment includes: a lifting device, a swing device, a front and rear buffer device, a left and right buffer device, a pincer rod 14 and a frame 5, wherein the swing device is installed on the upper part of the lifting device, and the pincer rod 14 is installed on the lifting device. At the bottom of the device, the front end of the front and rear buffer devices is connected to the front suspension rod 12 middle part of the lifting device, and the rear end is connected with the frame 5, and the left and right buffer devices are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com