Two-freedom rotary decoupling parallel robot mechanism

A degree of freedom, robot technology, applied in the direction of moving/orienting solar collectors, manipulators, solar collectors, etc., can solve the problems of large cumulative error, installation at one point, and many moving pairs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

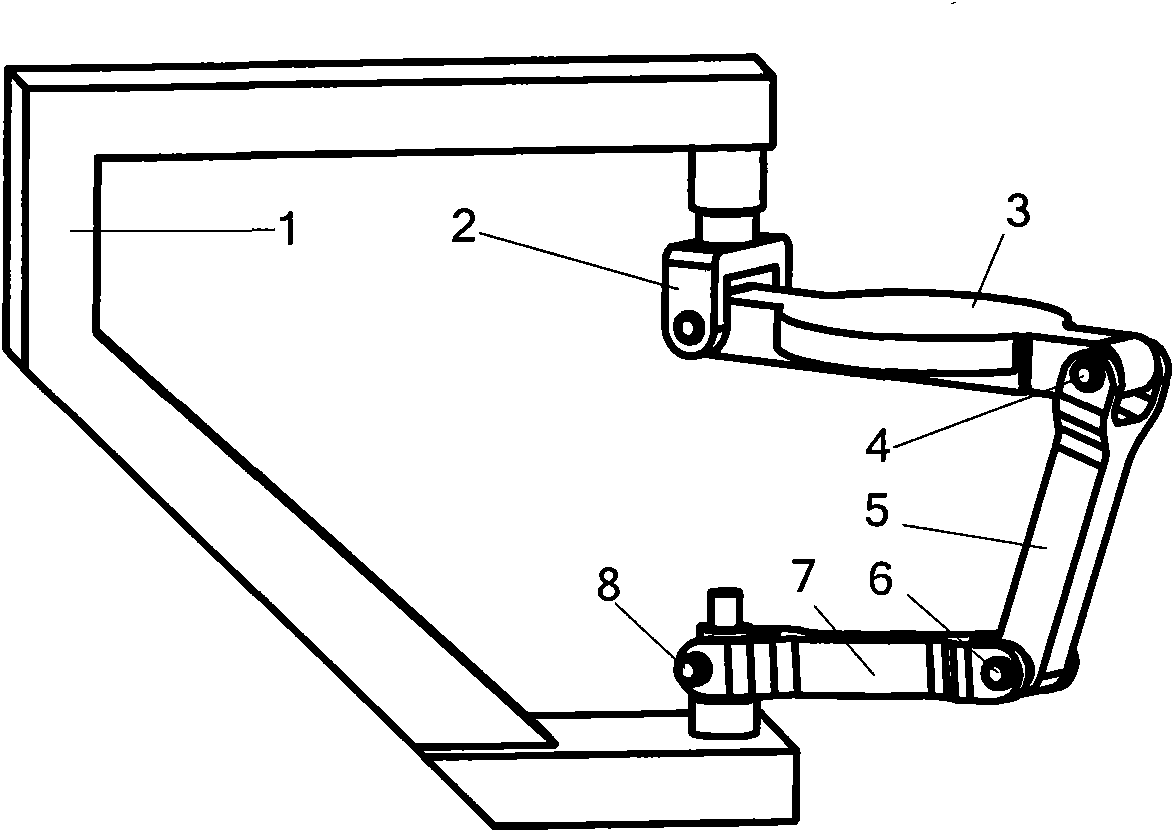

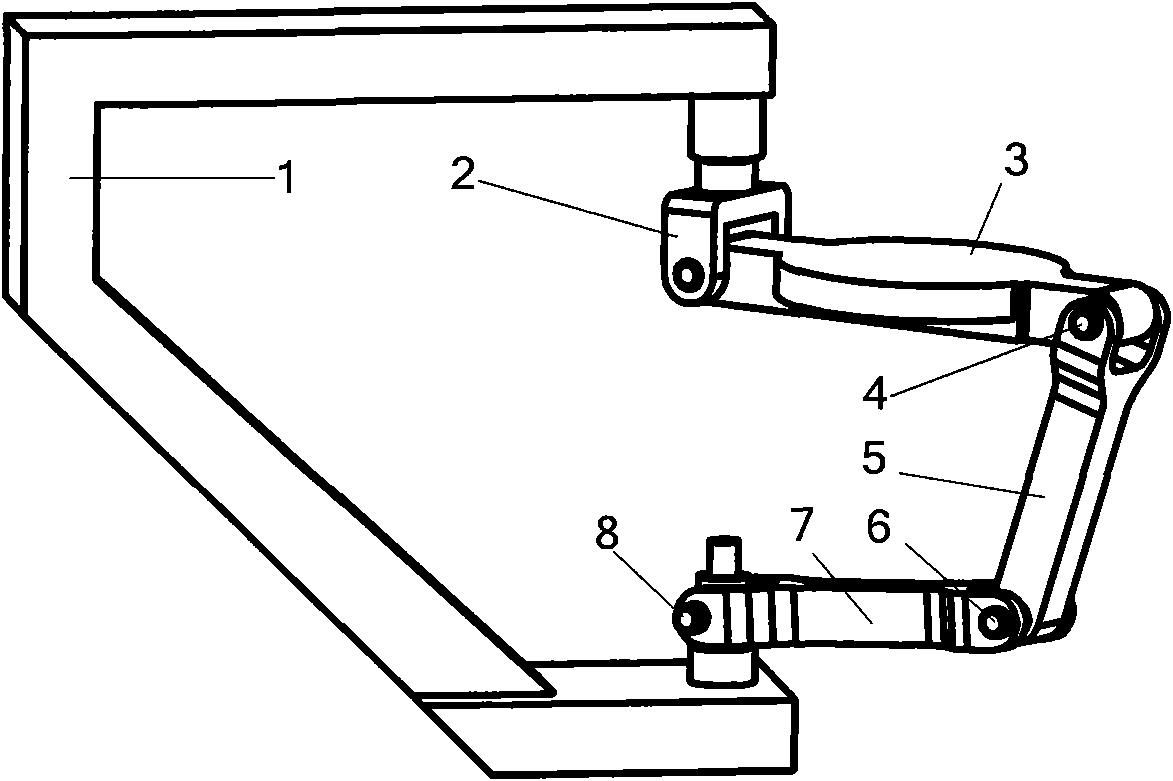

[0012] The moving platform 3 of this mechanism is connected with the fixed platform 1 through 2 branches (see figure 1 ). There is only one Hookee hinge 2 in the first branch. The rotating pair 4 of the second branch connects the moving platform 3 and the connecting rod 5, the rotating pair 6 connects the connecting rod 5 and the connecting rod 7, and the connecting rod 7 is connected with the fixed platform 1 through a Hooke hinge 8. An axis of the Hooke hinge 2 of the first branch and an axis of the Hooke hinge 8 connected to the fixed platform 1 of the second branch are collinear, and the other axis of the Hooke hinge 2 of the first branch and the second The axis of the rotating pair 4 whose branch is connected with the moving platform 3 remains parallel.

Embodiment 2

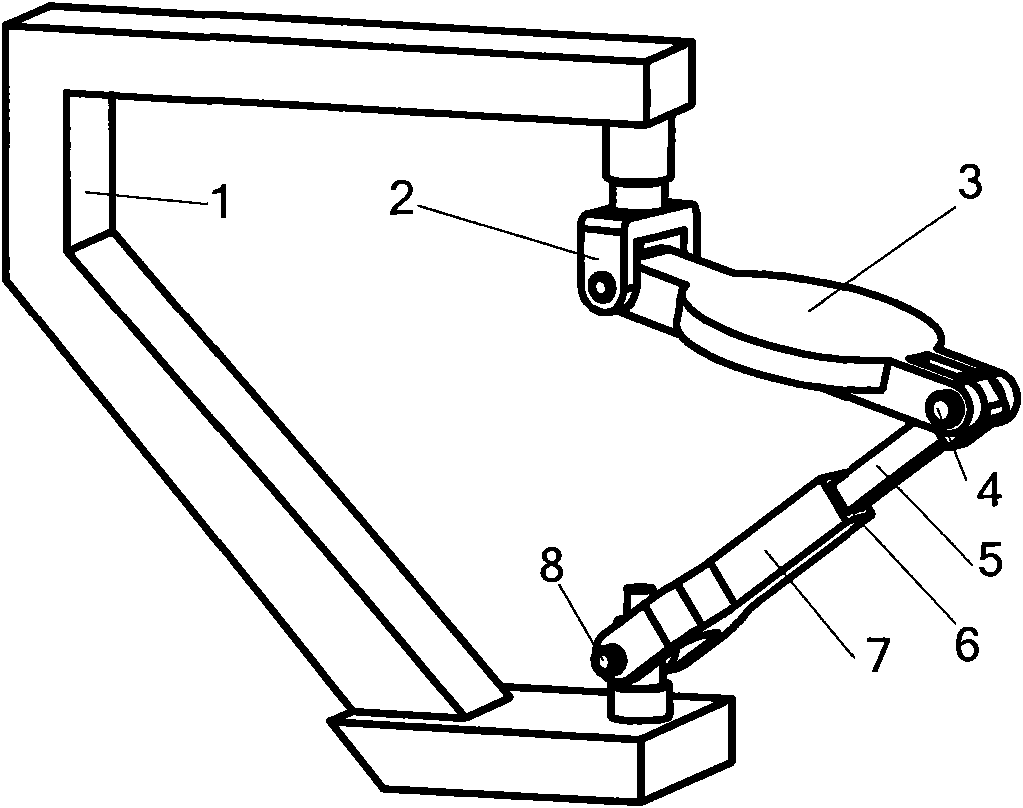

[0014] The moving platform 3 of this mechanism is connected with the fixed platform 1 through 2 branches (see figure 2 ). There is only one Hookee hinge 2 in the first branch. The rotating pair 4 of the second branch connects the moving platform 3 and the connecting rod 5, the moving pair 6 connects the connecting rod 5 and the connecting rod 7, the connecting rod 7 is connected with the fixed platform 1 through the Hooke hinge 8, the Hooke of the first branch One axis of the hinge 2 and one axis of the Hooke hinge 8 whose second branch is connected to the fixed platform 1 are collinear, and the other axis of the Hooke hinge 2 of the first branch and the second branch connected to the moving platform 3 The axes of the revolving pair 4 remain parallel.

[0015] The space two-degree-of-freedom rotation decoupling parallel robot mechanism of the present invention has good kinematics performance, high flexibility and large working space; its kinematics positive and negative sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com