Electric control car controller

A technology of electric vehicle controller and relay, applied in excitation or armature current control, electrical components, vehicle components, etc., can solve the problems of DC power damage, slow diode turning speed, and failure to turn off the motor power supply, etc. The failure speed is slow, the effect of avoiding relay adhesion and avoiding power over-discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

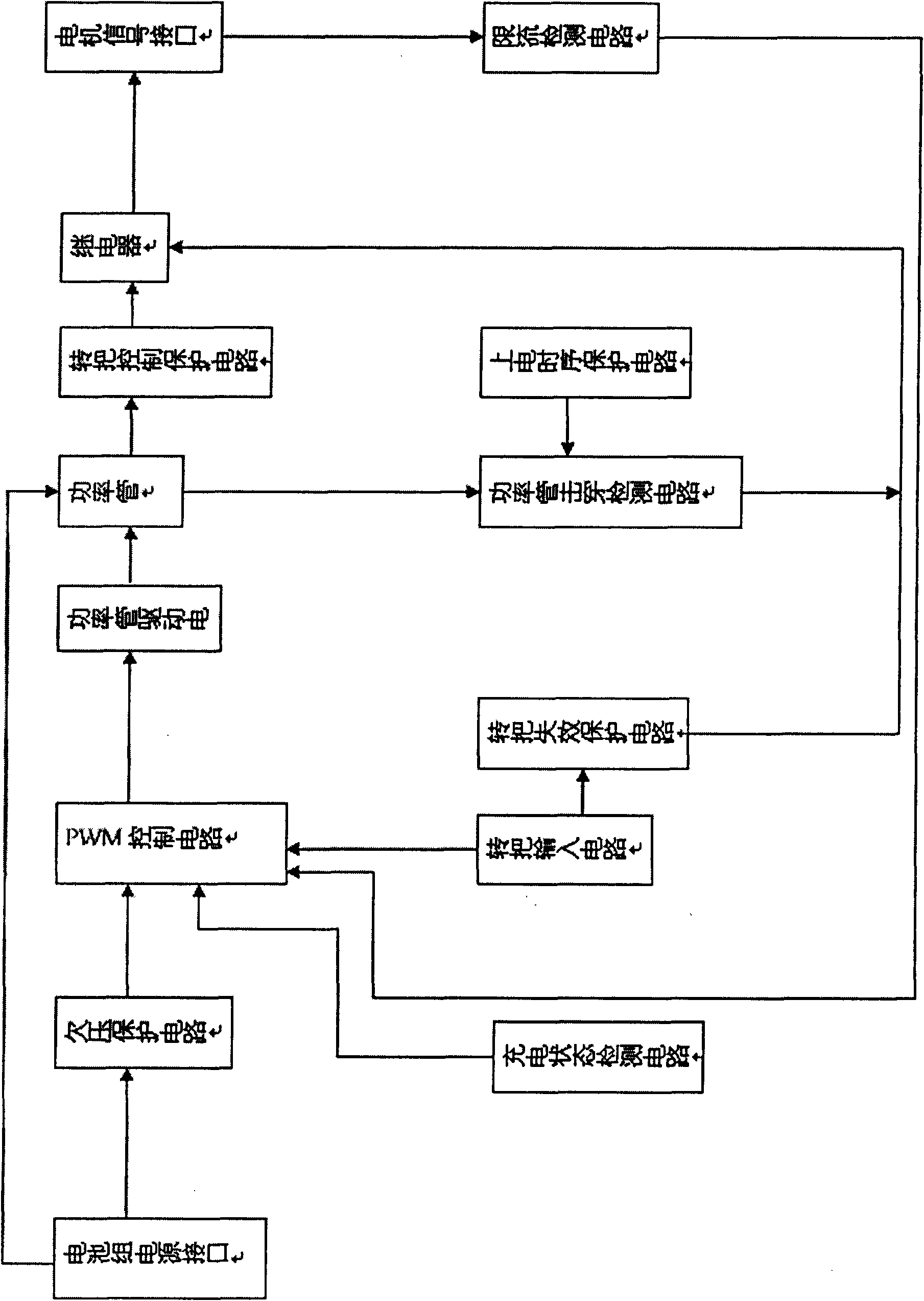

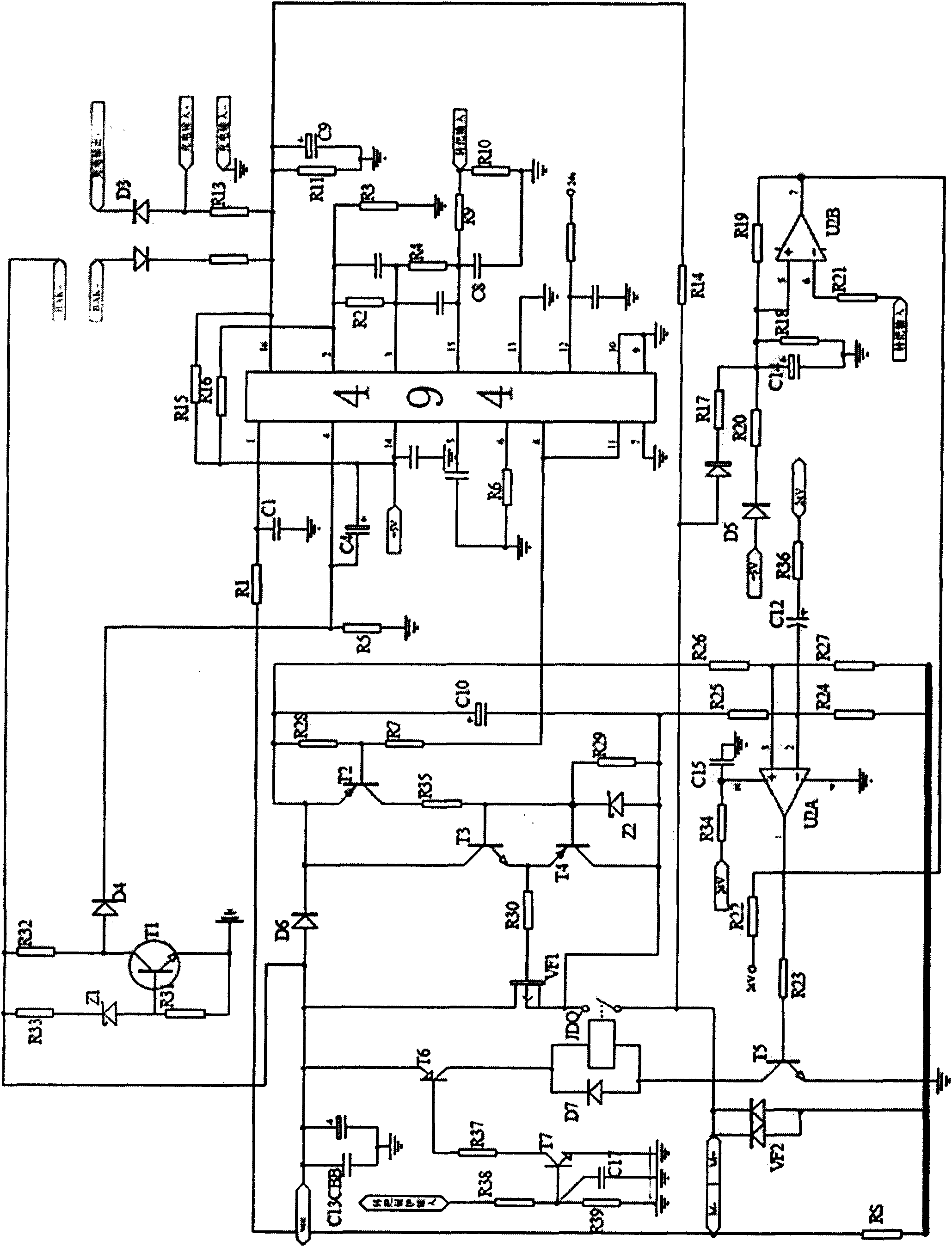

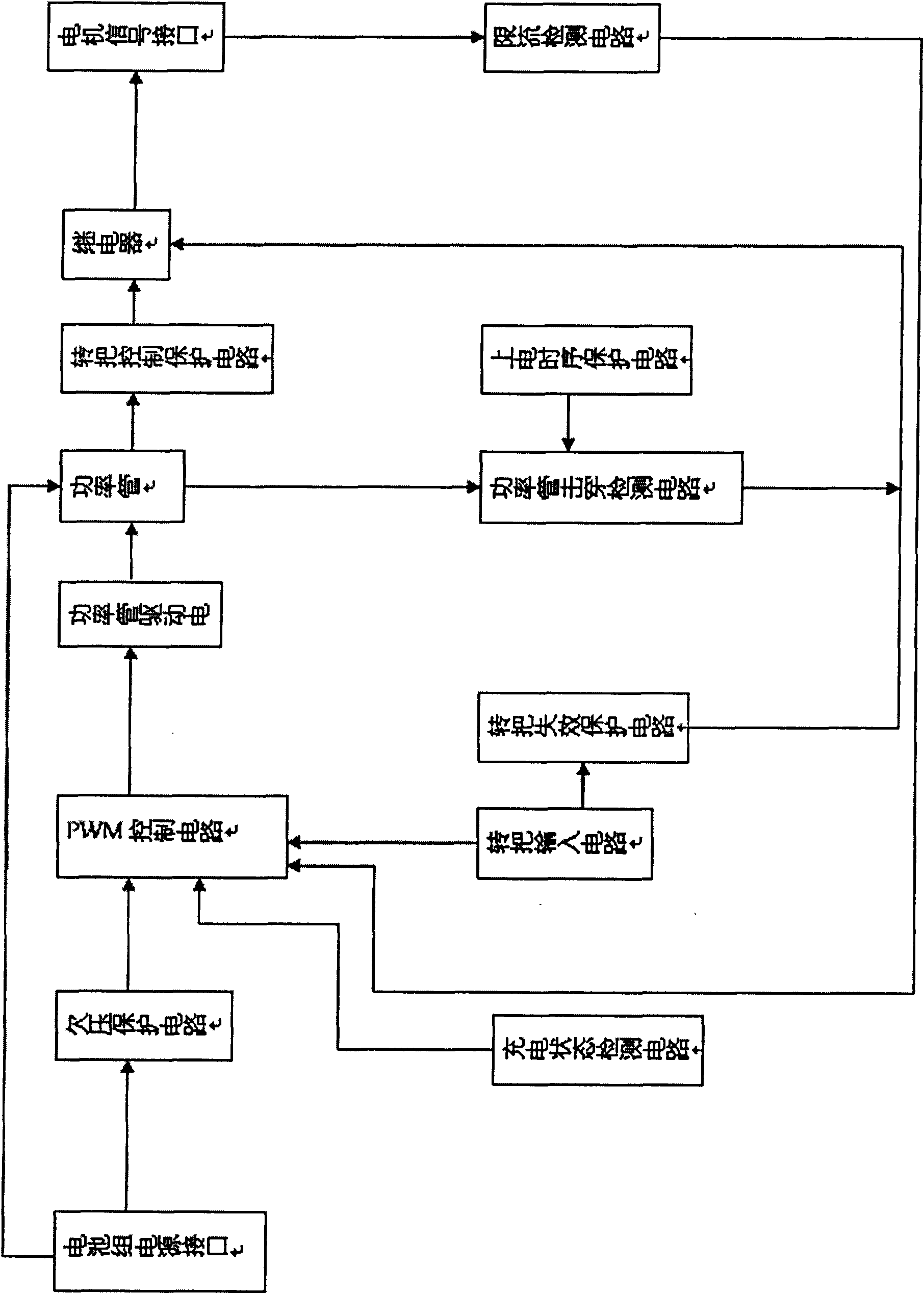

[0038] like figure 1 As shown, the undervoltage protection circuit, PWM control circuit, power tube drive circuit, power tube and relay are sequentially connected between the battery pack power interface and the motor signal interface, and the current-limiting detection circuit is connected between the PWM control circuit and the motor signal interface. During the period, the power-on sequence protection circuit is connected between the power interface and the power tube breakdown detection circuit, the power tube voltage stabilization protection circuit is included in the power tube drive circuit, and the power tube breakdown detection circuit is connected between the relay and the power tube. The fail-safe circuit is connected to the control circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com