Direct-current charging heating control method, device and circuit, vehicle and storage medium

A DC charging and heating control technology, which is applied in the field of circuits, vehicles and storage media, devices, and DC charging and heating control methods, can solve the problems of main relay load disconnection and relay adhesion, so as to improve safety and avoid relay adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

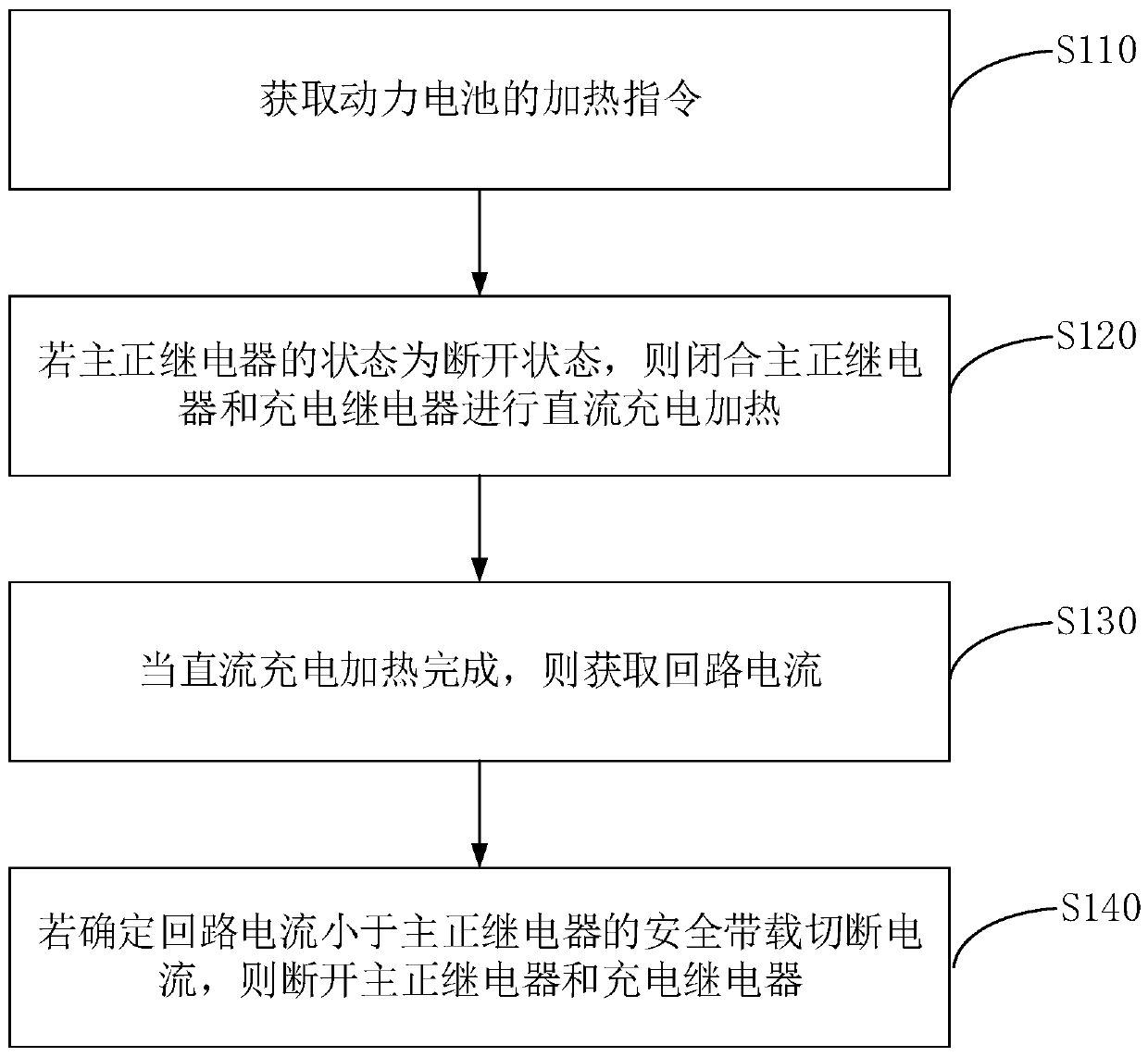

[0044] figure 1 It is a flow chart of a DC charging and heating control method provided in Embodiment 1 of the present invention. This embodiment is applicable to the situation of controlling the DC charging and heating of power batteries in electric vehicles. The method can be controlled by a DC charging and heating control device For execution, the device may be implemented in the form of software and / or hardware, and the device may be configured in a controller in the vehicle, such as a motor controller. Such as figure 1 As shown, the method may specifically include:

[0045] S110. Obtain a heating instruction of the power battery.

[0046] Wherein, the power battery may be a battery configured on an electric vehicle, and the specific type and quantity are not limited in this embodiment. The heating command is used to control the power battery for charging and heating.

[0047] Specifically, when the power battery needs to be charged and heated, the heating instruction ...

Embodiment 2

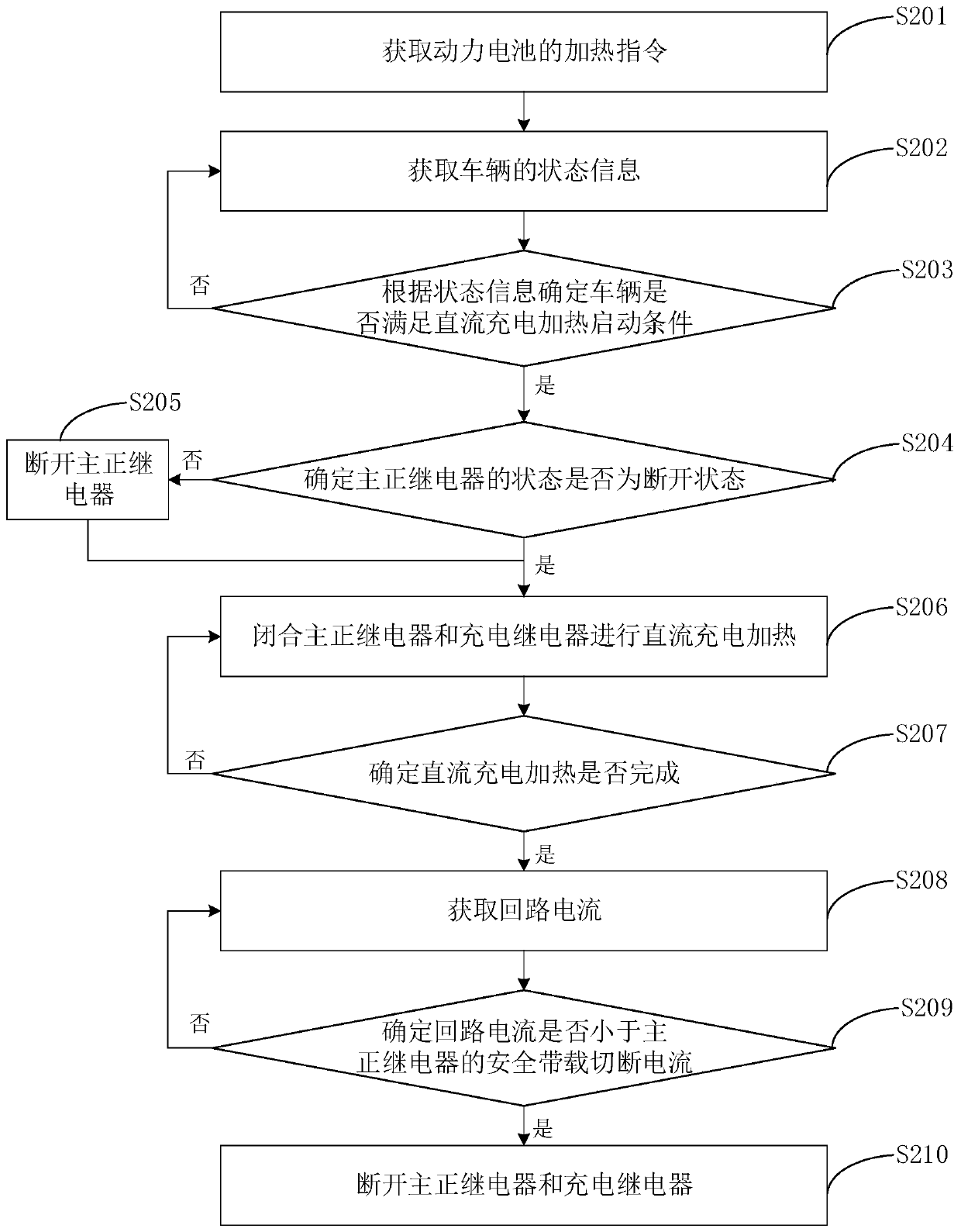

[0066] figure 2 It is a flowchart of a DC charging heating control method provided in Embodiment 2 of the present invention. In this embodiment, on the basis of the above embodiments, the above-mentioned DC charging and heating control method is further optimized. Correspondingly, such as figure 2 As shown, the method of this embodiment specifically includes:

[0067] S201. Obtain a heating instruction of the power battery.

[0068] S202. Acquiring status information of the vehicle.

[0069] Wherein, the status information may include status signals of various devices in the vehicle. In this embodiment, the type of information included in the state information is not limited, and may be determined according to actual conditions. For example, the state information may include the state signal of the gear position of the vehicle, the state signal of the ignition switch, the state signal of the charging port, and the like.

[0070] S203. Determine whether the vehicle sati...

Embodiment 3

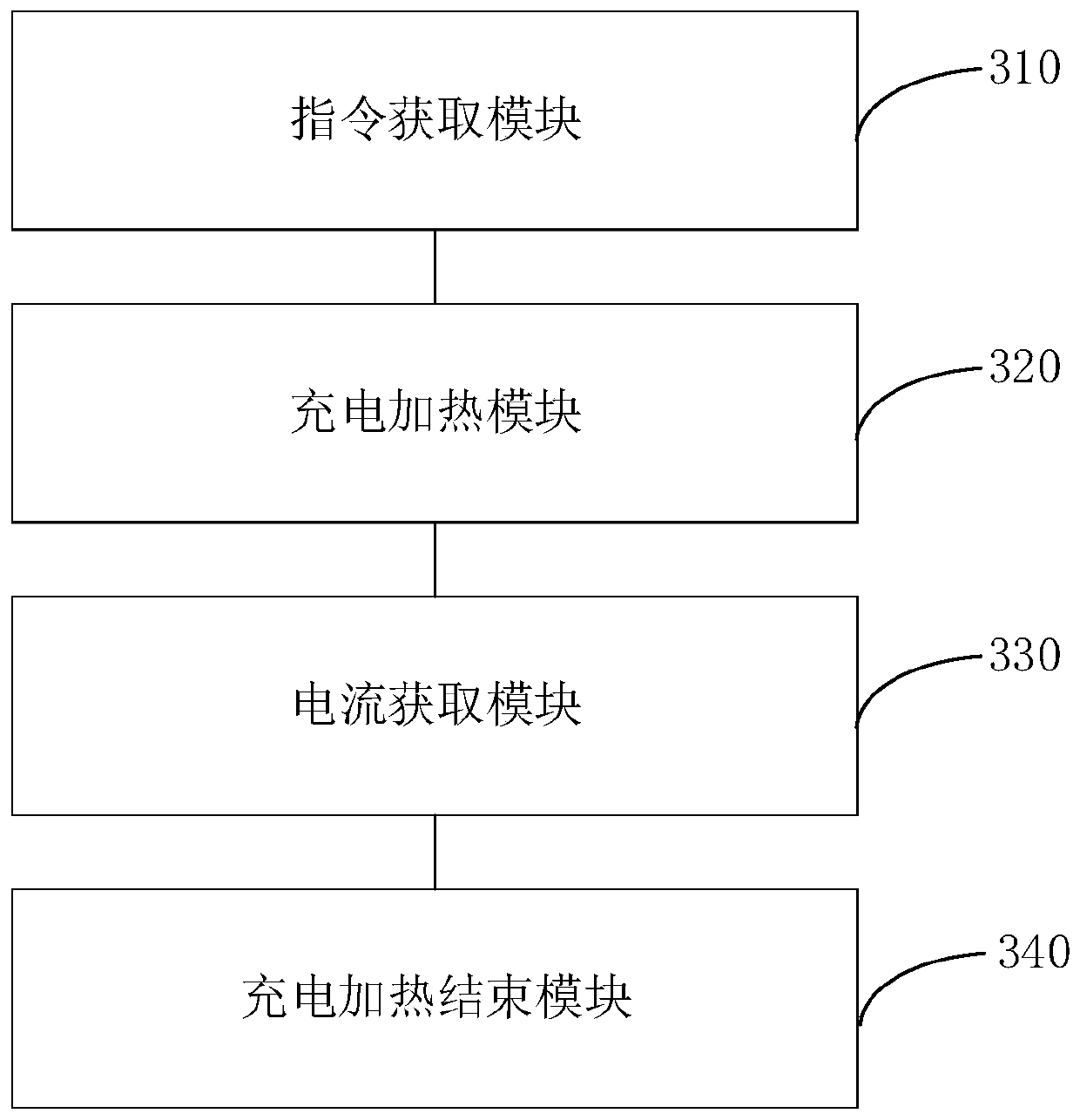

[0089] image 3 It is a schematic structural diagram of a DC charging and heating control device provided in Embodiment 3 of the present invention. This embodiment is applicable to the situation of controlling the DC charging and heating of a power battery in an electric vehicle. The DC charging and heating control device provided in the embodiment of the present invention can execute the DC charging and heating control method provided in any embodiment of the present invention, and has corresponding functional modules and beneficial effects for executing the method.

[0090] The device specifically includes an instruction acquiring module 310, a charging and heating module 320, a current acquiring module 330, and a charging and heating end module 340, wherein:

[0091] An instruction acquiring module 310, configured to acquire a heating instruction of the power battery;

[0092] The charging and heating module 320 is used to close the main positive relay and the charging rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com